Lubricant trends

Advances in automotive lubricant design

04 March 2025

13 September 2017

Enabling fuel economy and durability in tomorrow’s formulations

As emissions and fuel economy legislation tighten the world over, the need for advanced lubricants is increasing. This means formulators are demanding more from the complex components at the heart of engine oils so that they can deliver differentiated products. Insight explores the performance of advanced viscosity modifiers and looks at the lubricant formulation challenges they can help to solve.

Governments across the world are working to meet carbon reduction targets, which means vehicle fuel economy targets are being introduced and/or tightened in most regions. The automotive industry is responding with new technology innovations and by improving the performance of conventional internal combustion engines. In addition, OEMs have a significant interest in achieving fuel economy improvements by reducing the viscosity of engine oils.

Viscosity modifiers are key enablers of lubricant fuel economy.

Infineum has been working to develop new advanced componentry to meet industry requirements for cost effective fuel economy improvement combined with superior engine protection.

By delivering excellent viscosity control at both high and low temperatures; the latest Infineum viscosity modifiers can deliver measurable fuel economy gains. At the same time, they offer all of the benefits of current chemistries at low treat rates.

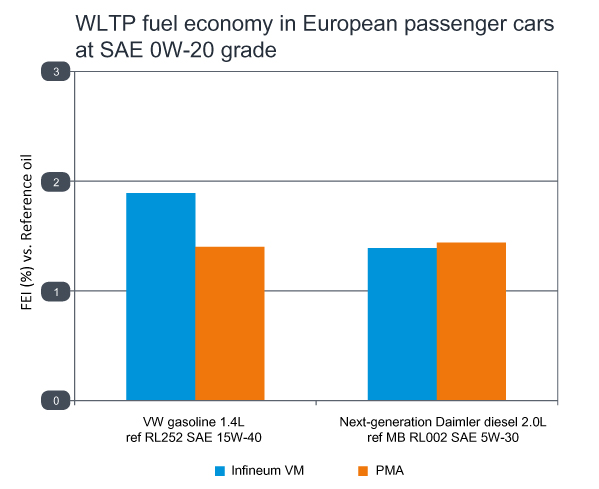

Fuel economy performance has been demonstrated in diesel and gasoline European passenger cars under the New European Driving Cycle (NEDC), Worldwide harmonized Light vehicles Test Procedure (WLTP) and in Japanese cars under the JC-08 and FTP-75 cycles.

Infineum VM fuel economy performance achieved at one third of the treat rate of the Polymethacrylate (PMA) fuel economy formulation

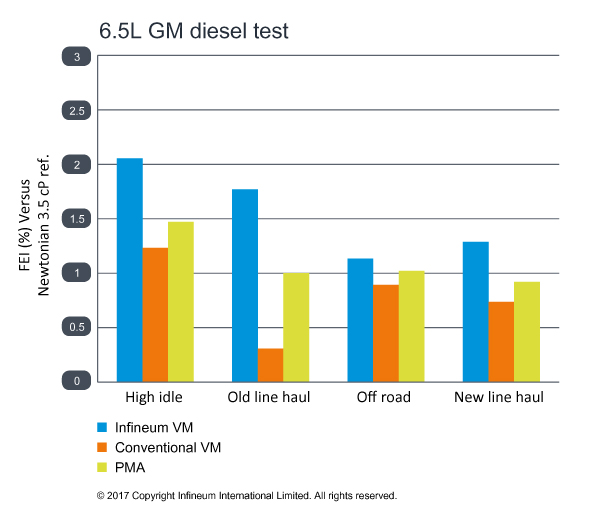

Infineum VM fuel economy performance achieved at one third of the treat rate of the Polymethacrylate (PMA) fuel economy formulationIn addition, fuel economy performance has been measured in a heavy-duty diesel engine using the 6.5L GM diesel test, which shows good correlation with real-life fuel efficiency. The Infineum VM consistently showed significant fuel economy improvement compared to a conventional VM and PMA, especially in line haul cycle.

The Infineum VM delivered fuel economy improvement in the 6.5L GM diesel test

The Infineum VM delivered fuel economy improvement in the 6.5L GM diesel test

While lubricant derived fuel economy improvement is increasingly important, it should not come at the expense of hardware protection.

The tightly controlled molecular structure of advanced VMs means they are very shear stable and highly resistant to viscosity loss due to mechanical stress – ensuring advanced engine protection.

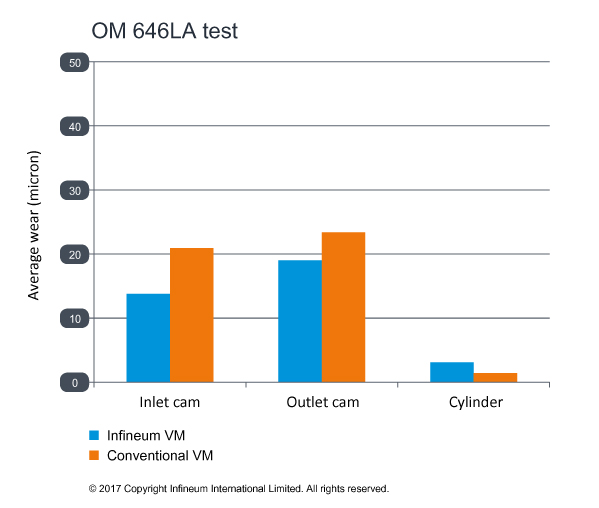

Wear performance has been assessed using the OM 646LA test. At 5% soot, the Infineum VM has significantly reduced cam wear.

In the OM 646LA the Infineum VM delivered better viscosity control and reduced cam wear

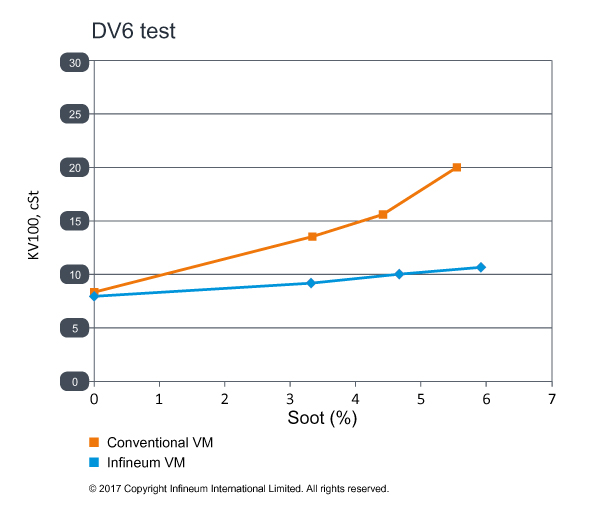

In the OM 646LA the Infineum VM delivered better viscosity control and reduced cam wearThe Infineum VM demonstrated excellent soot dispersancy in both passenger car and heavy-duty diesel formulations using the DV6 and Mack T11 tests at reduced treat rate. In addition, it offers desirable control of soot-induced KV100 and HTHS150 viscosity increase.

The Infineum VM demonstrated excellent soot dispersancy

The Infineum VM demonstrated excellent soot dispersancyThe Infineum VM also demonstrated good sludge control in both heavy-duty and passenger car tests from key OEMs. Its excellent wear and durability performance have also been confirmed in field trials in Europe, US and Asia.

In addition to wear and durability, it is essential that fuel economy improvement is combined with the other desirable VM performance features such as engine cleanliness and retained low temperature pumpability.

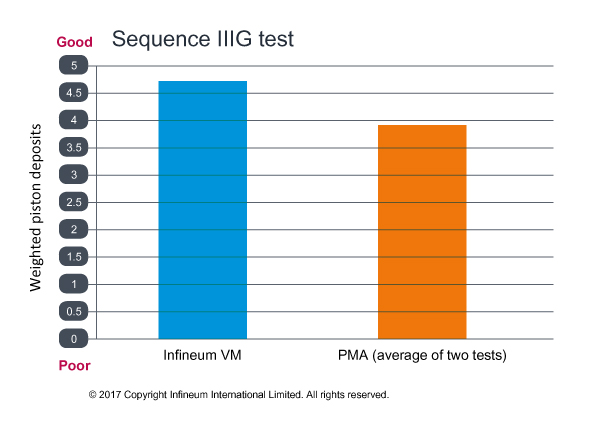

Piston cleanliness performance was assessed in the Sequence IIIG and the TEOST 33C. In both, the Infineum VM demonstrated excellent deposit control.

Excellent engine cleanliness performance was also demonstrated in both passenger car and heavy-duty diesel formulations using both the VW TDi2 and the Daimler OM501LA engine tests.

The Infineum VM demonstrated excellent deposit control performance in the Sequence IIIG test

The Infineum VM demonstrated excellent deposit control performance in the Sequence IIIG test

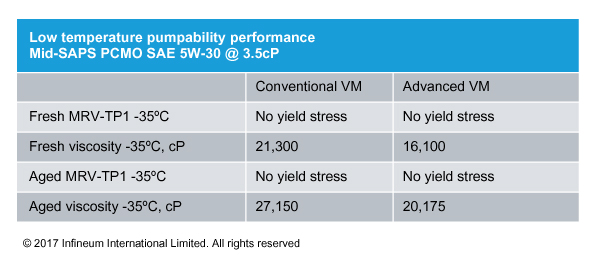

Low temperature pumpability performance was assessed in both fresh oil and in aged oil that had run in a field trial for 10,000 km in 3.5L engines.

The Infineum VM retained excellent pumpability performance after ageing. This means that reliable cold starting and operation is ensured throughout the oil drain interval.

In a cost conscious world, reducing servicing bills and keeping vehicles reliably on the road for longer is increasingly desirable.

The high shear stability and excellent soot control delivered by VMs are key enablers to ensure there is less engine wear and less lubricant viscosity increase, allowing oil drain intervals to be reliably extended.

VMs offer desirable formulation flexibility in terms of wide viscosity grade coverage and minimal PAO usage for formulating certain viscosity grades.

In addition, fuel economy benefits can be achieved in both passenger car and heavy-duty applications by using the latest VMs at lower treat rates than PMA.

The latest Infineum VMs offer an attractive suite of performance features for tomorrow’s formulation needs.

These VMs have been designed to retain the optimal shear stability and thickening efficiency balance, robust low temperature pumpability, and excellent engine cleanliness performance. Additionally, fuel economy credits, comparable to those delivered by PMA, are demonstrated by lubricants formulated using these VMs at a fraction of PMA treat rates.

Their advanced features, such as soot handling, have been shown to translate into engine wear and durability credits, which are crucial for achieving extended oil drain intervals. Lastly, their desirable formulation flexibility and component compatibility offer great potential for logistic convenience and cost savings.

Based on the articles you've read

Sign up to receive monthly updates via email