Lubricant trends

Advances in automotive lubricant design

04 March 2025

13 January 2016

Viscosity modifiers deliver technologically advanced lubricant formulations

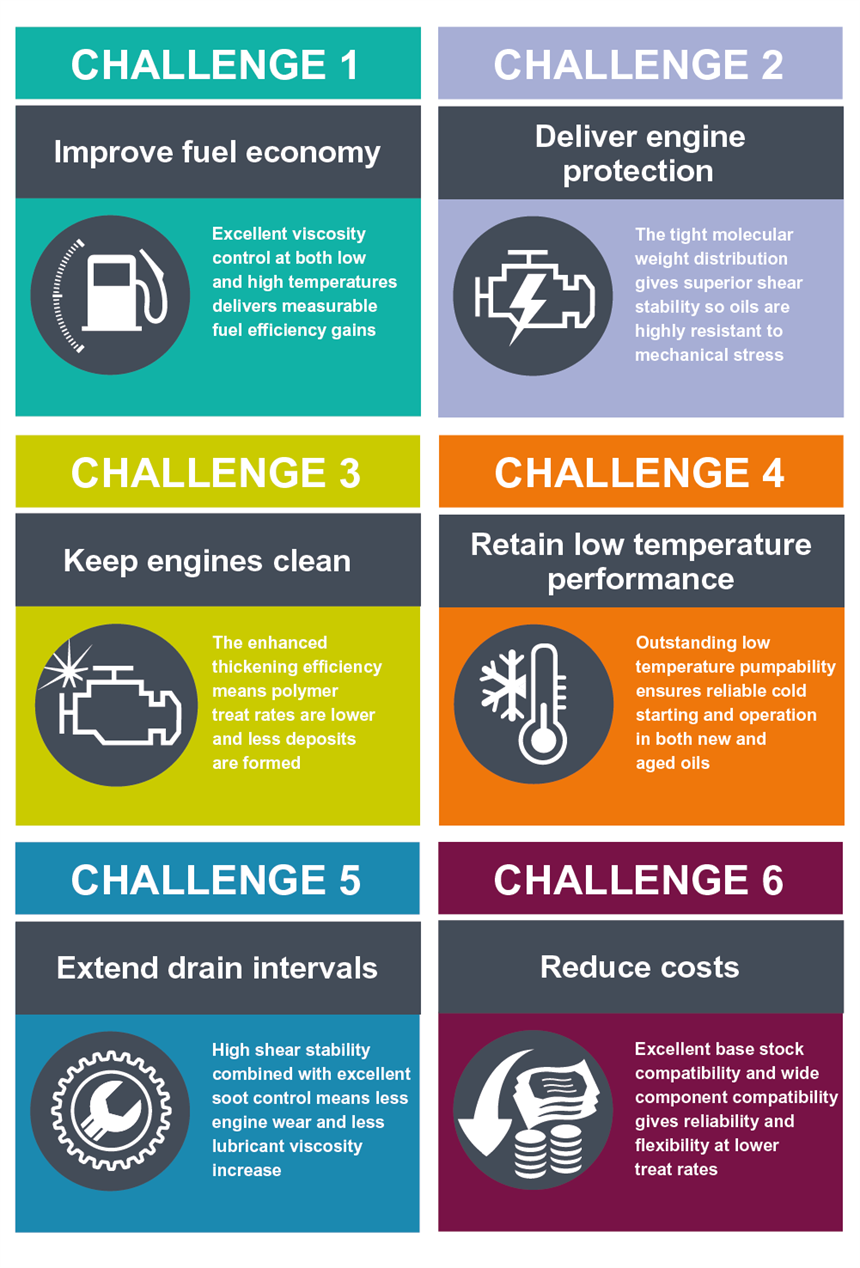

As emissions legislation tightens and OEM and customer requirements become increasingly demanding, formulators expect even more from the complex components that lie at the heart of engine lubricants. Our infographic and video explore how advanced viscosity modifiers can deliver outstanding performance and help to solve a number of lubricant formulation challenges.

Watch our video for a closer look at how viscosity modifiers can deliver technologically advanced lubricant formulations.

How viscosity modifiers deliver technologically advanced lubricant formulations Infineum International Limited

Infineum technologists have created a family of high performance viscosity modifiers to meet the demands of modern engines and gruelling service conditions. The Infineum SV series features an optimal balance of thickening efficiency and shear stability with outstanding low temperature properties.

The unique star structure is manufactured by a ionic polymerisation of diene and styrene monomers followed by hydrogenation, this process results in an amorphous polymer with narrow molecular weight distribution, the resulting polymer structure leads to excellent low temperatures performance in both fresh oils and oils aged in rigorous laboratory procedures and in the field giving excellent cold start properties under the most severe conditions and retaining pump ability through the next oil change. The amorphous structure of Infineum SV’s does not co-crystallise with pour point depressants and base stocks, this also gives additional flexibility and economy in the selection of pour point depressants in interchange among base stocks, saving on costs and assisting in additive rationalisation. What’s more, unlike other viscosity modifiers, Infineum SV stars can provide unrivalled balance between thickening efficiency and shear stability. The arms of the star are of uniform length giving optimised molecular weight distribution to minimise treat rate and resulting in a low contribution to the cold cranking viscosity. This means you can afford to use a heavier base oil in your formulation, to give improved volatility without compromising low temperature specifications. The unique star structure can provide excellent shear stability as it allows the molecule to self-compress and reduce resistance to flow under high shear condition, without mechanical degradation, at the same time this change in shape is fully reversible ensuring that the molecular structure provides and maintains a sufficient oil film thickness for greater wear protection. Infineum has now developed a star technology for use as a fuel economy enabler through careful selection of polymeric building blocks, an architecture has been defined which contracts at low temperature to minimise viscous energy losses at cold start and typical engine operating temperatures and at peak temperature the star polymer expands to enhance oil film thickness and provides protection from wear. Infineum SV stars give you the best of both worlds, the optimum balance of thickening efficiency and shear stability you would expect from an exceptional quality viscosity modifier that gives the formulator flexibility and opportunity for cost savings.

Please use the contact form here to request more information

Sign up to receive monthly updates via email