Marine engines

Unlocking the full potential of methanol

16 April 2024

Please note this article was published in June 2016 and the facts and opinions expressed may no longer be valid.

03 June 2016

Helping marine and gas engine applications to reap the benefits of Group II base stocks

As the production of Group I base stocks continues to fall an increasing number of engine oil formulators are looking to use more widely available Group II products. Insight looks at some of the challenges and benefits this shift could bring to marine and gas applications.

Trends in automotive crankcase lubricant formulations, which account for over half of the base stock utilisation, are impacting the supply and demand balance of base stocks globally. As this sector looks to improve fuel economy and reduce emissions, their use of high quality Group II and III base stocks is growing. The inability of Group I products to deliver the right characteristics for automotive applications has resulted in a number of capacity reductions and plant closures in Europe, which have reduced supply by over a million tonnes.

Over the same period there has been a significant increase in the availability of Group II base stocks as new plants and capacity additions have come on stream. This has driven down their cost, making their use in applications other than automotive crankcase oils increasingly attractive. With further capacity additions scheduled over the next two to three years, a shift to these higher quality products in both gas engine and marine applications seems fairly inevitable.

Group II base stocks have a number of benefits over their Group I counterparts when formulating trunk piston engine oils (TPEO) for medium-speed, four-stroke engines. These include:

However, using Group II to develop TPEO also presents lubricant formulation challenges – particularly concerning asphaltene handling capabilities.

Most of the ships that use TPEO run on heavy fuel oil, which contains large polyaromatic species known as asphaltenes. And, during engine operation, these species can migrate into the engine oil via fuel contamination. Here they can agglomerate to form ‘black sludge’, which leads to high levels of deposit formation and results in piston deposits, choked oil galleries and oil starvation.

Deposits on the piston undercrown are of particular concern because they act as insulation, preventing the lubricant from effectively transferring heat away from the piston, which can lead to hot corrosion of the piston crown.

Oils formulated in Group I base oils with salicylate technology have demonstrated excellent performance, over many years of field operation.

Not only do they offer excellent asphaltene handling capabilities, but also excellent engine protection, extended oil drain intervals and reduced operating costs. But, the picture is very different when Group II base stocks are used. Their lower solvency means conventional additives are less able to handle asphaltenes, and a new additive system is required to ensure TPEO formulated in these high quality base stocks deliver the required level of engine cleanliness.

Steve Ames, Managing Director of global base stock market analyst firm SBA Consulting, gives his view on the ability of Group II to replace Group I in marine applications. “It has been the practice to use Group I base oils to formulate TPEO for four-stroke marine engines,” he confirms. “Their solubility helps keep heavy fuel asphaltenes in the drip oil, that drains into the crankcase, from plating out as deposits on the piston undercrown. The same was true for the system oil (SO) of crosshead engines. In recent years however, new additive packages have been developed that allow blenders to also use Group II base oils in their TPEO and SO formulations.”

Infineum has developed a new additive booster package, which has been rigorously tested in the laboratory and in field trials. When used together with salicylate-based TPEO additive technology, it addresses the asphaltene handling deficit of TPEO blended with Group II base stocks.

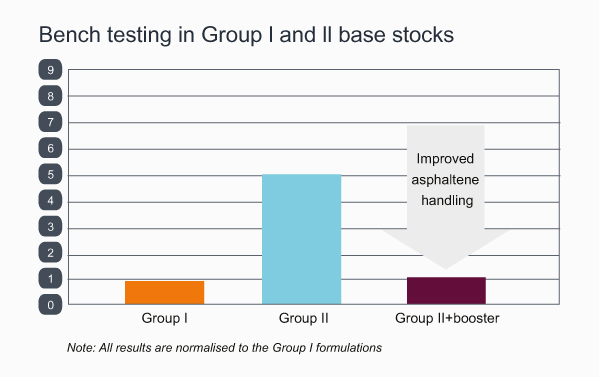

The new additive demonstrated an improvement in asphaltene handling in Group II base stocks

The new additive demonstrated an improvement in asphaltene handling in Group II base stocksTPEOs blended using Infineum technology in Group II base stocks deliver the level of performance and protection that marine lubricant formulators expect from Group I products. In addition, the booster enables them to reap the oxidation control, base number retention and slower viscosity increase benefits Group II base stocks can deliver.

Until recently, Group I base stocks have been the basis of most stationary gas engine oil formulations. But again, just as in the marine market, the increased availability and lower cost of Group II means this picture is changing.

Group II base oils offer performance improvements in most aspects of lubricant testing. The improved oxidation control they can deliver is of particular interest in the latest high efficiency engines.

These advantages mean that we are seeing some OEMs, including MTU, MWM Waukesha and Rolls Royce, starting to request Group II only formulations.

To meet changing market needs, Infineum has developed a mainline gas engine additive system designed for use in Group II base stocks. Using salicylate technology combined with world-class components it delivers a number of benefits:

In addition to these strong benefits, the new technology has good base number retention, which means it is still protecting the engine at the end of the oil drain, a factor that enables longer drain intervals to be introduced.

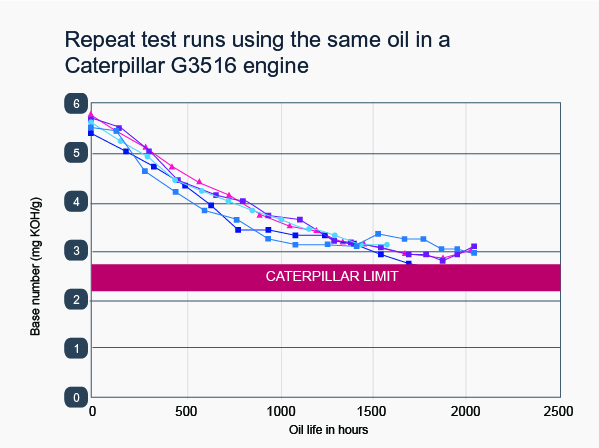

The technology has been tested extensively in the laboratory and delivered more than 2,000 hours of trouble free operation in engine tests.

Infineum technology demonstrated consistent base number retention in over 2,000 hours of engine testing

Infineum technology demonstrated consistent base number retention in over 2,000 hours of engine testingField testing is currently underway in a variety of different engines. Results to date indicate that the excellent oxidation performance obtained in bench testing is being confirmed.

The new additive system offers robust engine protection at low treat rates and is particularly suitable in Group II base stocks, in line with market evolution.

These new Infineum marine and gas engine technologies formulated in Group II base stocks have been tested extensively to ensure they meet the requirements of today’s engines.

The aim is to deliver the same – or even enhanced – levels of performance and protection that have come to be expected from Group I products. At the same time, these new products are designed to enable lubricant marketers to reap the commercial, oxidation control, base number retention and slower viscosity increase benefits that can be gained by formulating in Group II base stocks.

Sign up to receive monthly updates via email