Fuels

Reported sludging incidents rise

04 November 2025

08 July 2025

Combustion improver technology delivers benefits beyond fuel efficiency across a wide range of vessel types

Ship operators are using fuel additives as a cost-effective way to help reduce fuel consumption as they work to cut running costs and emissions. But, their value goes way beyond these well-recognised attributes. In this article, Adrian Bourdeaux, Marine Fuels Technology Manager, shares the findings of recent evaluations at sea, carried out in a range of vessel types. These data not only confirm the emissions and efficiency improvement fuel additives can deliver to marine applications but also show how they can keep hardware clean and improve scrubber performance.

The maritime industry is working towards a net zero emissions future by 2050, where alternative fuels such as methanol, ammonia and hydrogen will be more widely used. However, in the transition period, conventional hydrocarbon fuels will continue to be the dominant marine fuel. To remain compliant with International Maritime Organization (IMO) regulations and to meet IMO net zero aspirations, while also cutting costs, ship operators and owners need to reduce emissions and improve efficiency today. These were some of the key drivers that prompted Infineum to develop novel combustion improver fuel additive technology.

Initially, our technologists put a significant amount of effort into static engine, no-harms, and field proof of concept testing – you can read more about the results here. This article goes on to describe how the results of this highly controlled development program have been replicated across multiple vessel and engine types and sizes in the last 18 months. In addition, it shows how this extensive testing has uncovered a number of other benefits combustion improver additives can deliver.

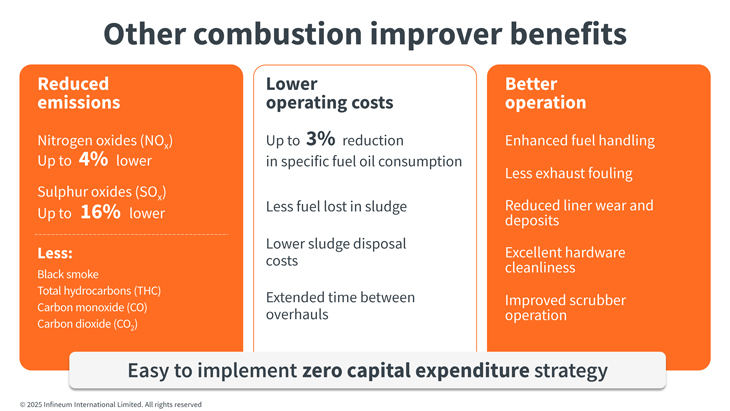

In our first trial, despite the adverse weather conditions encountered throughout the additised portion of the trial, we achieved a 1% specific fuel oil consumption (SFOC) saving and reduced emissions of nitrogen oxides (NOx), and sulphur oxides (SOx) by 4% and 12% respectively.

Our technology has received the first ever Lloyd's Register Fuel Additive Statement of Fact for improved SFOC, reduced NOx, and carbon monoxide (CO) emissions.

To some readers a 1% fuel efficiency gain might not sound like a huge improvement. But, as an example, it would mean a single vessel consuming 100 MT of fuel per day could gain a net annual saving of some $3 to 4 million*.

Encouraged by this strong performance, we have completed a series of successful field evaluations across a wide range of vessel types, including cruise liners, container ships, and bulk carriers. Building on this foundation, the technology is now being adopted more broadly, with several ongoing commercial deployments and new collaborations underway. Many of these initiatives are being driven by the additional operational and environmental benefits that are now consistently being demonstrated in real-world applications.

Infineum works hard to ensure that each field evaluation is as operationally controlled as possible, maintaining consistent speed, load, and other key parameters between baseline and additised phases. While each field evaluation differs in terms of vessel type, engine configuration, fuel quality, and operating environment, this variability has proven valuable. It demonstrates that, across a wide range of real-world conditions, we consistently observe improvements in SFOC.

In all our various sea trials the improved combustion has helped to reduce specific fuel oil consumption by between 1 and 3%.

Both our technical teams and our sea trial partners have been really pleased with the results we have obtained. Why? Because not only have our additives provided the expected fuel efficiency improvements but also they have delivered a number of other valuable benefits.

The IMO is introducing new emissions control areas (ECAs) where tighter limits have been introduced for air pollutants including NOx, SOx and particulate matter. The Mediterranean ECA came into force from May 2025 and Canadian and Norwegian seas become NOx ECAs from 1 March 2026, and SOx ECAs from 1 March 2027. In addition, several other countries, including China, Australia and South Korea, have nominated their territorial waters to be future ECAs.

Ships entering these areas need to run on <0.1% sulphur fuels or install exhaust gas cleaning systems – the decision on which is generally based on cost. Whatever approach is taken, ships sailing through these waters can gain additional benefits from the use of combustion improver technology.

First, improved combustion can help to reduce emissions of a number of pollutants. In our trials we have seen a reduction in the emissions of:

Linked to reducing emissions, we have also found that using additised fuel helps to improve the performance of scrubbers on board ships.

IMO’s Marine Environment Protection Committee (MEPC) has issued guidance on wash water discharge parameters such as pH, turbidity, Polycyclic Aromatic Hydrocarbons (PAH), and temperature. However, the enforcement of these limits is determined by local/national authorities. As such, ship operators using scrubber systems must ensure compliance with the specific requirements of the jurisdictions in which they operate.

In our evaluations, when operational conditions were constant, the scrubber wash water contained up to 20% less PAH indicating more complete combustion.

We also saw up to 19% reduction in turbidity - an indirect indicator of improved combustion efficiency. This results in less particulate matter entering the scrubber, reducing sludge generation and associated handling requirements.

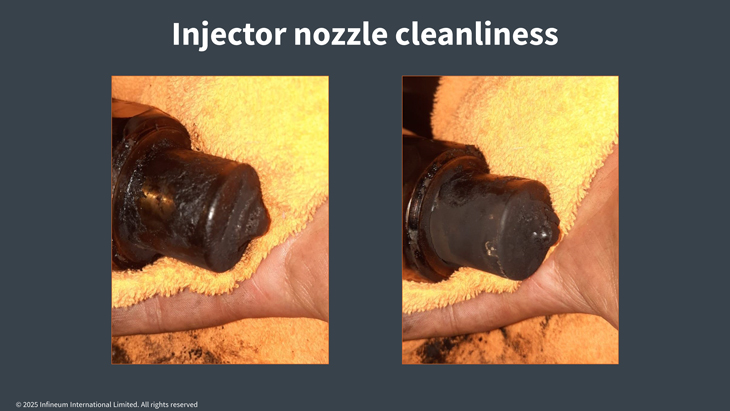

Injector nozzle cleanliness is an important factor since it prolongs injector lifetime and promotes effective fuel atomisation into the combustion chamber, which ensures better combustion and improves the effectiveness of combustion catalysts.

During the evaluation of our additives at sea we have seen less build up of hard deposits on the injector nozzle openings - an observation that has been confirmed by our partners.

"When I opened the engine I was surprised, I usually see black combustion residual, but using additive it looked like they are more new, almost like halfway [of normal operating hours]. I removed injectors, cleaned, and they were still working Myself, 1st Engineer all looked at them and agreed. They joked that maybe I had made a mistake with the running hours!."

Chief Engineer on sea trial vessel

Images of injector nozzles from additive sea trials showing clean spray holes

Images of injector nozzles from additive sea trials showing clean spray holes

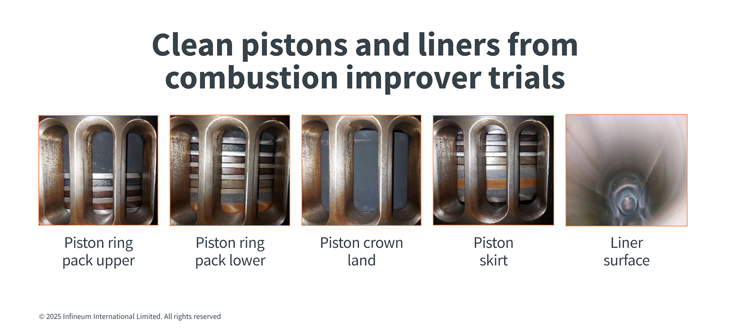

Engine cleanliness is another important factor that helps to ensure reliable and efficient engine operation - keeping ships in operation for longer and extending time between overhauls. On inspection, the pistons and liners when the ships were run on additised fuels demonstrated extremely good cleanliness levels throughout operation.

"Overall impression [of additive use] was that it is clean, the engine was not dirty [compared to normal], there were no residual deposits. Components were clean and emissions looked better."

Chief Engineer on sea trial vessel

Images of pistons and liners from additive sea trials showing excellent cleanliness

Images of pistons and liners from additive sea trials showing excellent cleanliness

Additionally, these fuel additives have the ability to improve fuel system cleanliness and operability, ultimately reducing fuel lost as sludge and contributing to an improved Carbon Intensity Indicator (CII) rating.

The use of combustion improver fuel additives that have been extensively tested and independently verified can clearly help to reduce fuel consumption and CO2 emissions. Their use is supported by IMO Resolution MEPC.346(78), which recognises fuel additives as a means to improve energy efficiency.

But, as we have demonstrated in sea trials, the benefits do not stop there - combustion improvers can also aid with critical areas of concern such as reducing black smoke, improving scrubber operation and minimising sludge.

Using combustion improver additives is an easy way to implement efficiency improvement and is a CO2 emissions reduction strategy that is available today. These fuel additives can contribute to an improved CII rating, without the requirement for capital expenditure, while also helping to reduce operating costs and downtime.

To explore how combustion improvers could benefit your fleet, contact our team at marinefueladditives@infineum.com

* fuel price at 400-650 $/MT

Sign up to receive monthly updates via email