Marine engines

Pioneers of maritime decarbonisation

15 May 2025

16 April 2024

Additives enhance methanol fuel properties and deliver cost savings, reliability and simplified logistics for shippers

The shipping industry is looking for the most effective decarbonisation strategies en route to the IMO’s 2050 net zero target. In this sector, switching to low or zero carbon fuels has some of the greatest potential to reduce greenhouse gas emissions, which is creating interest in the use of alternative fuels, including methanol. Dewi Ballard, Infineum Product Manager, talks to Insight about the growing use of methanol and the challenges related to its use in dual-fuel engines. He also explores the capabilities of methanol additives, their impact on engine performance, and how shippers can benefit from using additised fuels.

Under increasing pressure to reduce greenhouse gas (GHG) emissions to meet International Maritime Organization (IMO) decarbonisation targets, the maritime sector is considering a range of options to reduce emissions. However, IMO suggests that fuel selection, for both existing and new vessels, can offer some of the largest potential for GHG reduction, with methanol emerging as a front runner.

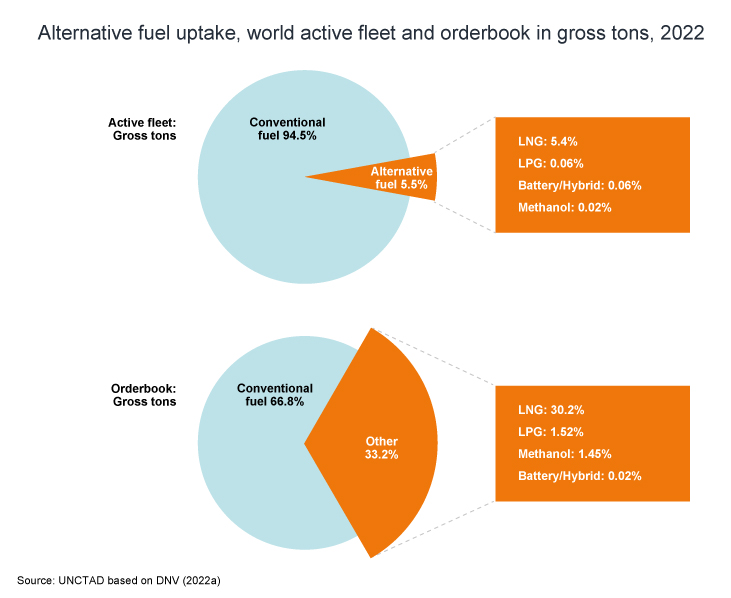

Based on the 2023 UNCTAD Review of Maritime Transport, only 5.5% of vessels (by gross tons) currently utilise alternative fuels, with the majority relying on LNG and only 0.02% on methanol. However, methanol has seen significant growth, accounting for nearly 5% of the alternative fuel orderbook in 2022. This trend continued in 2023, particularly after the maiden voyage of the Laura Maersk in September. Lateset figures suggest methanol is now at 8% of orderbook overall.

We have already seen, after the IMO low sulphur rules in 2020, how the introduction of regulations can have an impact on the bunker market dynamics. Now, as the industry works to meet the latest GHG targets, the market is shifting again. Currently alternative fuel sales are limited but showing signs of growth. The Port of Rotterdam reports that from January to September 2023, 7% of fuel sales were from alternative fuels such as LNG, biofuels and methanol, while Singapore has surpassed 1%.

In November 2020, methanol was approved for inclusion in the IMO's Interim Guidelines for Low Flash Point Fuels. Green methanol, which is produced from low carbon sources, such as sustainable biomass or carbon dioxide and hydrogen produced from renewable electricity, has the potential to be carbon free, and can meet emissions targets in terms of NOx, SOx and particulates.

There is an increased interest in methanol as a suitable compliant fuel from ship owners, ports and flag states, which could help to carry internal combustion engines well into the future.

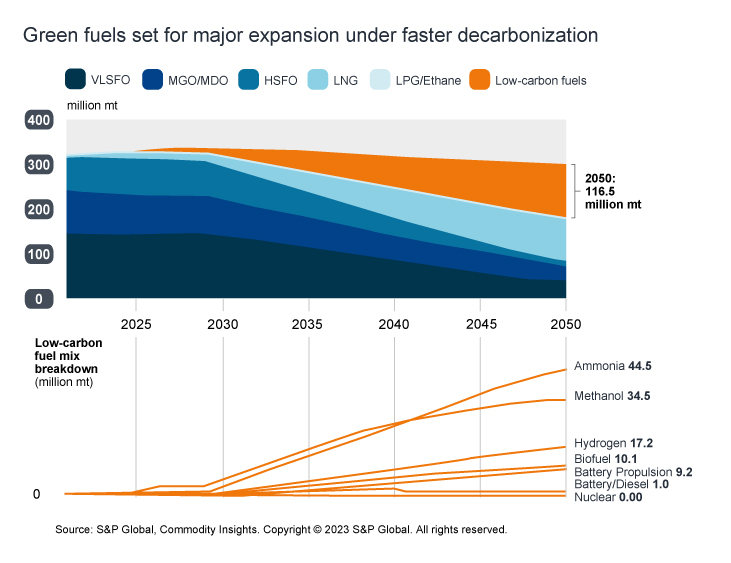

While today methanol uptake is in the early adoption phase, looking ahead, forecasters suggest that by 2030 it could lead low-carbon bunker fuel demand. Still further ahead, as fossil fuel options decline more rapidly, methanol is expected to continue to be a very popular low-carbon fuel choice for shippers.

One of the main reasons methanol is gaining ground in this sector is its compatibility with existing dual-fuel main engines. As bunkering facilities across the globe increase their methanol stocks, shippers will more readily be able to take advantage of this lower-carbon fuel.

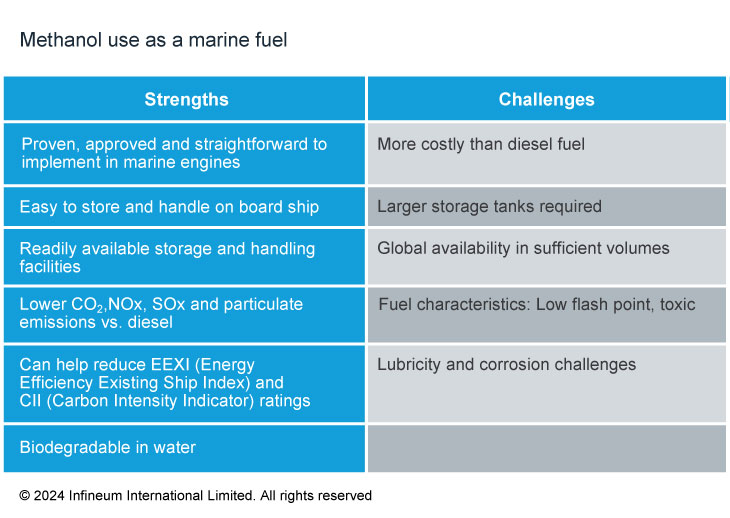

However, there are several upsides and challenges associated with its use as a marine fuel, which we believe the industry will address.

Methanol’s low viscosity and hygroscopic nature mean it faces a number of challenges related to lubricity and corrosion. Fuel additives, which are specifically designed to enhance fuel properties, can be used to address these issues and bring additional benefits to shippers. These can be easily blended at the refinery or added into bunker tanks prior to bunkering.

Lubricity refers to a fuel’s ability to reduce friction and wear within engine components. In methanol engines, maintaining proper lubrication is essential to prevent excessive wear to critical parts such as fuel pumps, injectors, and valves. Without adequate lubricity, these components can suffer premature damage, leading to reduced efficiency and increased maintenance costs.

Fuel additives can significantly improve lubricity performance in methanol powered engines by creating a protective film on the metal surfaces, thus reducing friction and wear. By incorporating them into methanol, shippers can not only ensure smoother engine operation but also prolong the lifespan of engine components.

Corrosion is a silent threat, occurring when fuel reacts with metal surfaces, causing their gradual deterioration. In methanol engines corrosion can affect critical components such as fuel lines, tanks, and valves. Corroded parts compromise safety, increase maintenance expenses, and potentially lead to fuel leaks or system failures.

Corrosion inhibitor additives can be used to combat metal degradation caused by methanol. These inhibitors form a barrier between the fuel and the surface of the metal to prevent corrosive reactions. By using additised methanol, shippers can safeguard their engines against corrosion-related damage.

One of the most significant advantages of additised methanol is its compatibility across different engine types. A major manufacturer of auxiliary engines, which provide an uninterrupted power supply to the various systems onboard a ship, reports that additised methanol has a lubricity performance equivalent to that of diesel fuel. This means that shippers can use the same fuel for both their auxiliary/generator engines and main engines. The benefits of bunkering a single fuel that caters to all onboard engines include simplified logistics, reduced storage complexity, and streamlined fuel management. Additionally, this unified bunkering approach eliminates the need for separate fuel storage, saving valuable space onboard.

Using fuel additives to minimise wear and corrosion when using methanol in marine engines can also help to reduce maintenance costs. Shippers can allocate resources more efficiently, focusing on operational excellence rather than repairing or replacing damaged engine parts.

Alternative fuels, such as ammonia, hydrogen and methanol, will have a key role to play in the drive to decarbonise the international shipping fleet. In our view, methanol could have a faster uptake than some of the other options since the engine technology is already in place.

High quality fuel additives hold the key to unlocking methanol’s full potential in shipping by enhancing lubricity performance and protecting against corrosion.

Shippers using advanced additives with proven chemistry will find methanol a reliable, efficient, and more sustainable choice for all their marine engines.

Sign up to receive monthly updates via email