Marine engines

Fuel additive sea trials

08 July 2025

05 March 2024

Partnering for marine lubricant field trials deliver short and long term wins for shipping companies

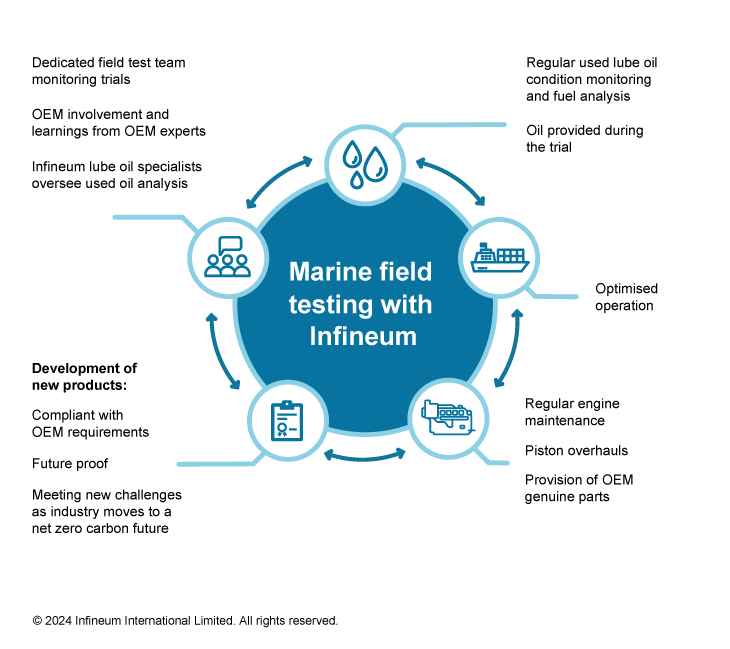

In the marine world there are no industry-wide specifications for engine oils. This means marine lubricants must undergo formal validation trials to obtain approvals from the major OEMs before they can be sold to vessel owners and operators. Hellen da Silva, Infineum Field Test Team Leader, explains how the partnerships Infineum forms with global shipping companies to run the extensive field trials needed to gain these approvals provide real win-win opportunities for everyone involved.

Obtaining an OEM approval (known as a ‘Main No-objection Letter’ or NOL) for a marine lubricant is a long and fairly complex process. Without this endorsement, suppliers are unable to sell their marine lubricant products to vessel owners or operators. Part of the validation is carried out, following OEM protocols and under OEM scrutiny, in vessels operating at sea, which brings added reassurance of product quality and reliability to end users. The challenge here is finding sufficient partners, running ships with an engine that meets the OEM requirements, who are prepared to run field trials with a test oil.

There are many reasons Infineum needs to run a lubricant validation programme on its marine additives for diesel cylinder lubricants (MDCL), trunk piston engine oils (TPEO) and system oil formulations. It may be necessary for example to:

As OEM engine hardware, operating patterns and fuel types continue to change, it becomes increasingly important to develop lubricant solutions that meet current standards and are also adaptable to meet future demands. This necessity highlights the importance of creating new partnerships with engine owners and operators to ensure our products are tested under real-world conditions that reflect both current and emerging engine technologies. But, to run an effective field trial, we need to find partners who can give us access to the right engine, running on the right fuel that is operating over sufficient distances. Through such forward-thinking collaborations, we aim to make sure our lubricants excel in a rapidly changing technological environment, secure their relevance and performance for the long term, and to ensure safe and reliable operation.

Our previous collaborations with shippers have been long-standing, mutually beneficial and very positive experiences. The knowledge accumulated from running trials over the past several decades has enabled us to understand from our partners the benefits that they can gain from partnering on these validation testing programmes.

Probably the most obvious is that the oil for the entire duration of the trial is provided free of charge. With field trials lasting many months, or even longer, this can result in significant cost savings for the operator.

In our view, the benefits of collaborative field trials go far beyond the cost savings.

Because the trial is overseen by the engine manufacturer, the crew and Superintendent receive inspection information from OEM experts at the start and end of test unit overhauls. This means that the crew and management can benefit from direct expertise, and engines can be operated at optimal efficiency and reliability throughout the trial. In addition, regular analyses of used lube oil and fuel are carried out throughout the trial. With dedicated Infineum marine lubricant experts and qualified marine engineers monitoring the project, insights into the oil and engine performance are also available. Infineum’s experts are dedicated to working closely with our partners which enhances the collective understanding of lubricant performance. We have found that a high performing oil can increase the lifetime of components, which can contribute to considerable long-term cost savings.

Something we are really proud of are the mutual benefits that can be derived from our field trials.

From our many years of experience we have gained an understanding of some of the concerns shippers may have regarding lubricant field trials. And, owing to the transparent relationships with our partners, we have also been able to understand how best to address them.

First, we find people may be concerned that there could be additional work for the crew. Here, we try to minimise crew workload as much as possible. Infineum engineers also board the ships during inspections to provide clear instructions and facilitate easy compliance, enhancing efficiency and understanding. Furthermore, we have a dedicated marine team based in both Europe and Asia-Pacific, ready to offer support and answer any queries, to facilitate seamless operation and quick resolution of any challenges.

Our approach ensures the tasks are more manageable and less time-consuming, reducing the burden on the crew and enhancing operational efficiency.

In addition, operators may be concerned about taking the ship out of service for analysis and inspections. However, we always work to fit in with the vessel schedule and available periods where the overhauls can be completed with minimum disruption.

There can also be a perception of increased risk when using a test oil. However, prior to any field trial, the products will have undergone rigorous testing to validate their performance.

Lastly, our marine field test team comprises experienced engineers, each with over 10 years of sailing experience. This ensures the engineers we send on board are competent and familiar with maritime environments. Moreover, our entire team and any contractors undergo comprehensive safety training, which emphasises our commitment to maintaining the highest safety standards on board.

Our extensive field trial experience means we have a number of successful case studies and partner testimonials to share. Here are examples of a couple of our field trial projects.

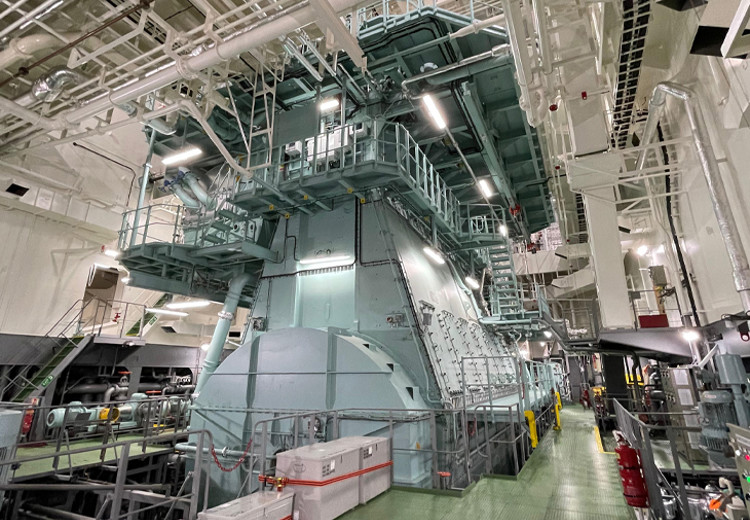

In a recent collaboration with a leading parcel tanker company, we conducted MAN-ES Category II trials on one of their vessels, which is powered by the MAN-ES 5G50ME engine and fuelled with very low sulphur fuel oil (VLSFO). To fulfill the requirements of a Category II trial, Infineum took the lead in coordinating a lubrication split, in partnership with the OEM, that allowed the engine to be lubricated by two different cylinder oils. This approach enabled a direct comparison between our candidate oil and a reference oil. To ensure a fair comparison between the two oils, both the test and reference units were overhauled at the beginning of the trial and, throughout the trial, the units operated under identical conditions for the same period.

After 2,500 hours of operation, our 40 BN product demonstrated superior performance over the 100 BN reference oil. The additive package we introduced effectively controlled deposit buildup and reduced wear on pistons and liners.

At the conclusion of the trial, Infineum was awarded with a NOL for a Category II trial from MAN ES, validating the outstanding performance of the product.

The trial's success has not only solidified our partnership with the tanker company but also opened doors for further collaboration. The company was so impressed with the results that we have continued testing on their vessel to further optimise the technology and develop even more advanced products. Following this successful partnership, our testing has been expanded to an additional vessel, underscoring the trust and confidence in our innovative solutions.

In another trial, we tested a new TPEO lubricant formulation in a Class 1A cargo vessel powered by a Wärtsilä 6L38B engine. The initial test was scheduled to run for 4,000 hours – about one year of engine operation. After this period, at the inspection the ship Superintendent told us: “We inspected two pistons and the engineers said they had never seen such a clean engine before.”

Because the results were so good, the trial continued for over 20,000 hours and at the end of the trial the excellent performance achieved meant Infineum received OEM approval for the new product.

Ship-based field trials are the only way to confirm a marine lubricant product meets a specific manufacturer’s requirements for their engine. By using products that carry an OEM approval, users can be confident that what goes into their engines will deliver the protection and performance needed to keep it running reliably for longer – which means less maintenance, lower operating costs and more up time.

In the long run, particularly with the rapid pace of decarbonisation in the marine world, new products, compatible with lower carbon fuels, such as methanol, hydrogen and ammonia, will be needed. Once our bench and fired engine testing has been completed, the performance of these new products will also need to be confirmed in the field. We will rely on shippers and operators to help us deliver the future lubricant solutions needed to help meet the decarbonisation challenge.

We are looking to create new partnerships to validate a range of both existing and future marine lubricant products. If you are interested in taking part then please email marinefieldtestteam@infineum.com to start the conversation.

Sign up to receive monthly updates via email