Marine engines

Fuel additive sea trials

08 July 2025

05 September 2023

New proven combustion improver additive solution can help ships to meet tightening mandates

Finding affordable, effective and achievable ways to improve fuel consumption and reduce emissions is of growing importance to the marine industry. Following his paper at this year’s CIMAC Conference, Adrian Bourdeaux, Infineum Marine Fuels Technology Team Leader, talks to Insight about some of findings from a rigorous test programme that demonstrated the ability of combustion improver additives to reduce emissions and save fuel in marine engines running on either very low or high sulphur fuel oils.

The marine industry is under increasing pressure to decarbonise, with the International Maritime Organization’s (IMO) Marine Environmental Protection Committee (MEPC) adopting a revised greenhouse gas (GHG) strategy in July 2023.

The IMO revised GHG strategy includes an enhanced common ambition to reach net zero GHG emissions from international shipping close to 2050.

In addition there is a commitment to ensure an uptake of alternative zero and near zero GHG fuels by 2030 as well as indicative check points for 2030 and 2040. Shippers must act now and, with data collection underway for the new Carbon Intensity Indicator, they are looking for ways to improve fuel economy to ensure a rating of C or better is achieved. At the same time, in a tough economic climate the industry is also trying to reduce running costs. These factors can be positively influenced by reducing fuel consumption – particularly when you consider fuel costs can represent some 50–60% of the total operating costs of a vessel.

Fleet operators already have a raft of efficiency options to choose from including, for example, slow steaming, hull cleaning, the use of solar and wind power and voyage optimisation, but some of the largest potential GHG reductions come from fuel selection.

Forecasts suggest that by 2030, 5% of the energy for shipping should come from carbon-neutral fuels.

However, while the industry waits for new energy options, such as methanol, hydrogen and ammonia, to be widely commercially available, it is possible to gain fuel savings and reduce emissions today, without capital investment, by using proven combustion improver additives.

Effective combustion improvers can help to cut vessel fuel consumption, lower the CO2 output per nautical mile travelled and reduce other key emissions, such as NOx, providing shipowners with a reliable fuel additive toolkit to help align with future regulatory drivers.

In the past, the potential benefits of using marine fuel combustion improver additives has been questioned. With this in mind, Infineum ran a rigorous test programme, designed to provide statistically significant data, in order to fully evaluate the impact of these additives. Scoping tests were run on multiple formulations in a static Caterpillar MaK 6M20 four-stroke test engine at a range of speeds and loads in both high sulphur fuel oil (HSFO) and very low sulphur fuel oil (VLSFO). Following a ‘base fuel-additised fuel-base fuel’ (B-A-B) cycle, enabled the data to be rigorously analysed to ensure that improvements attributed to the additive were genuine.

The testing not only measured fuel consumption but also continuously monitored emissions of carbon monoxide (CO), carbon dioxide (CO2), nitric oxide (NO), sulphur dioxide (SO2), total hydrocarbons (THC) and filter smoke number (FSN). In addition, key combustion performance parameters, such as chamber pressure and heat release were assessed to gain a better understanding of the impact of the fuel additive.

In over 70 test days, Infineum built a significant understanding of the impact of additive chemistries. This knowledge was used to develop a novel combustion improver fuel additive product that delivered enhanced fuel consumption and emissions performance.

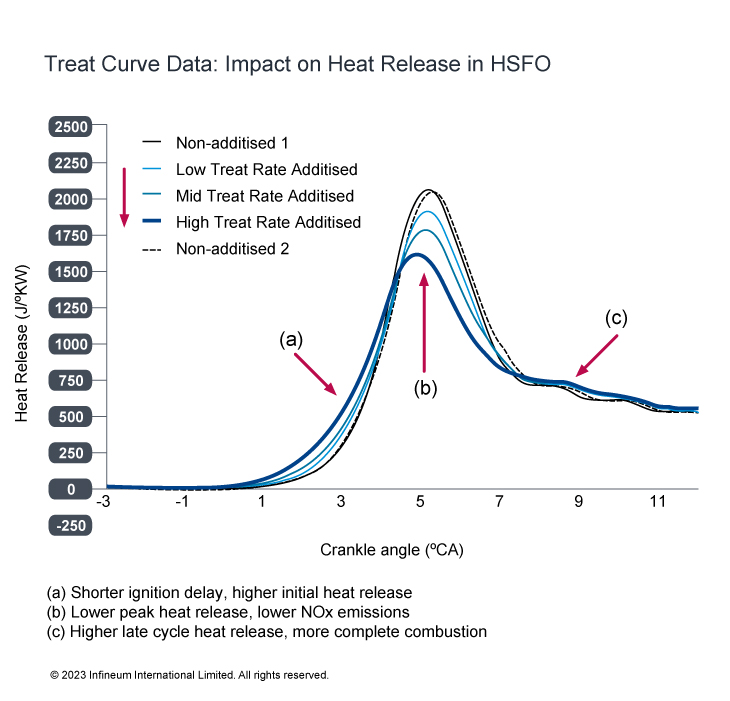

The chosen chemistries had the added benefit of providing fuel sludge management credits upstream of the fuel injector. In addition, the combustion improver additive reduced the ignition delay and increased initial heat release, improving combustion and work done vs. non-additised fuel. A lower peak heat release was also observed with additised fuel, which is known to reduce peak cylinder temperature, correlating to lower NOx emissions.

In static engine tests with HSFO fuel and the new combustion improver additive technology, NO emissions were reduced by up to 8.2%.

In addition, the more complete combustion of heavier longer-chain hydrocarbons resulted in lower FSN and hydrocarbon emissions along with fuel economy benefits.

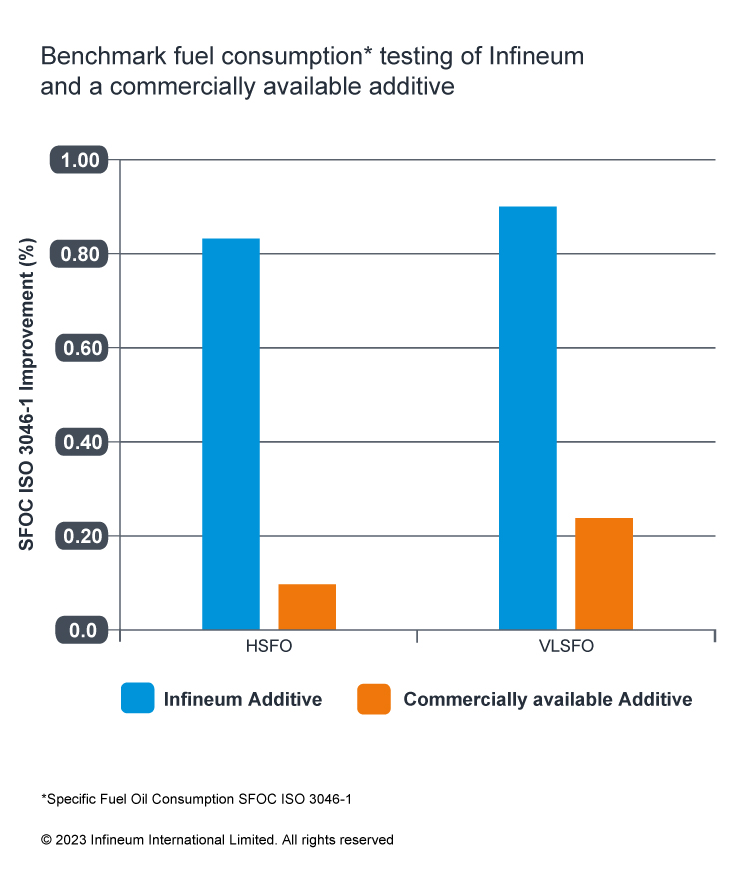

Testing the additive with VLSFO an average fuel consumption saving of ~1% was observed across all test days - lower than the 4% or more claimed by some commercially available additives. However, in our tests against a commercial additive at recommended treat rates the commercial benchmark yielded only marginal fuel economy improvement, and we were unable to replicate the claims made in relation to the technology.

The results from this testing indicate that the new Infineum combustion improver additive delivers significant and repeatable fuel economy and emissions reductions. In the next phase of our testing, the no operational harms for this new additive was confirmed in the Mitsui MAN B&W 4S50ME-T9.7 two-stroke static engine at various loads.

To verify the impact of Infineum combustion improver technology on fuel economy and emissions performance in real-life scenarios sea trials were run in a two-stroke 33,000 deadweight tonnage (DWT) chemical tanker.

Despite the harsh conditions encountered fuel consumption was reduced by 0.8%, which can be attributed to the fuel additive.

Key highlights of the field trial that can also be attributed to additive use include:

In these trials we have observed that field performance correlates well to the static engine testing.

In a world that needs to meet ever tightening fuel economy and emissions reductions targets, the marine industry has a number of operational options at its disposal. However, the use of proven fuel combustion improver additives is a fast, effective, no harms solution that can help to achieve compliance with both existing regulations and future requirements. In addition, improving fuel economy in this way also helps to reduce operating costs without the requirement for capital expenditure.

These results are from the first of several trials, sign up here to receive further information on our marine field trials as they are published in Insight.

Sign up to receive monthly updates via email