Marine engines

Pioneers of maritime decarbonisation

15 May 2025

23 January 2024

New insights into lubricant formulation challenges in ammonia-powered marine engines

As the shipping industry works to reduce greenhouse gas emissions to comply with current International Maritime Organization requirements, it is also assessing ways to meet the 2050 net zero ambition. With ammonia emerging as one of the most promising zero carbon fuel options for shipping, Toby Stein, Infineum Business Transformation Manager, reveals some of the lubricant compatibility work Infineum has undertaken in support of making the use of ammonia as marine fuel a reality.

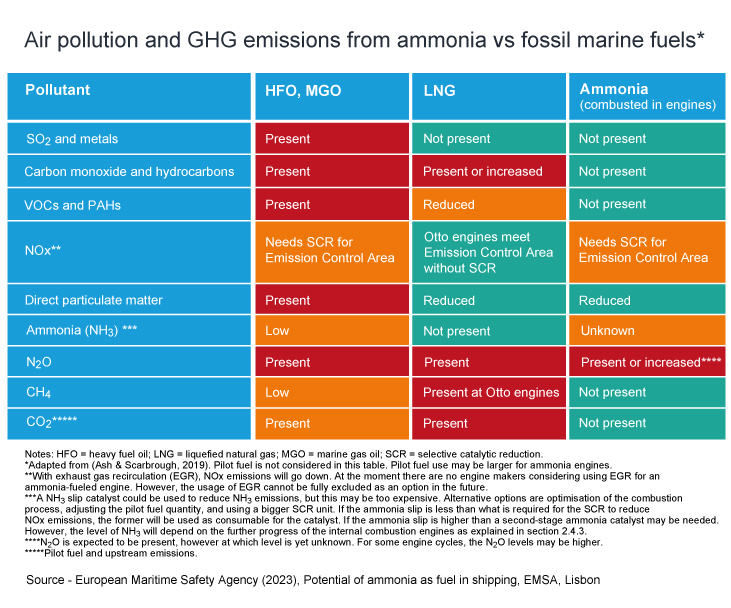

International shipping, which carries over 80% of world merchandise trade by volume, is reported to be responsible for nearly 3% of all global greenhouse gas (GHG) emissions. 2023 maritime CO2 emissions were 20% higher than 10 years earlier and, without further action, emissions from the sector are expected to continue to increase.

As the International Maritime Organization (IMO) works towards maritime decarbonisation, it is calling for a reduction in CO2 emissions of at least 40% by 2030 and 70% by 2040 compared to 2008. The organisation has also announced its ambition to reach net zero GHG emissions from international shipping by 2050. In response, the maritime industry has made significant investment in new engine and ship designs and in the infrastructure needed to accelerate the adoption of low or zero carbon fuels, which have the greatest potential to make a significant difference.

Lower carbon alternative fuels, such as biofuels, methanol, ethanol, LNG and LPG are already in use. But, looking ahead, fuels such as green methanol, hydrogen and ammonia, are expected to be the most promising zero carbon marine fuels, and the deep-sea shipping industry has championed ammonia.

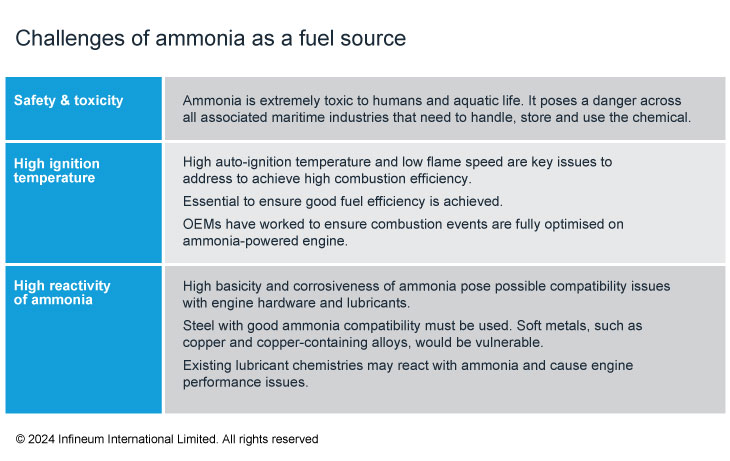

Ammonia is popular owing to its comparatively higher energy density (with respect to hydrogen) and the wealth of existing knowledge on ammonia handling, storage and infrastructure, which make it well suited to marine applications. However, safety and availability issues remain important barriers that need to be overcome before ammonia can be used at scale as a marine fuel. In addition, shippers say that both regulatory and customer support will be essential to support the installation of ammonia capable engines. Despite these concerns, two-stroke large engine OEMs, including MAN ES and WinGD, have already announced the rapid development of new engine designs and retrofitting strategies to enable ammonia adoption.

Many ship owners, including major shipping companies such as MSC, Grimaldi Group, Hoegh Autoliners, Euronav and CMA-CGM, are reported to be placing orders for new vessels ready to run on alternative fuels in order to give themselves more future fuels flexibility. As of the end of 2023, data suggest some 50% of these new orders have ammonia as an option. And, recent reports show Exmar LPG is moving forward with what may be the world’s first ocean-going ammonia dual-fuelled ships – set for delivery in 2026.

This fairly imminent arrival of ammonia fuelled engines raises numerous complex challenges to other tethered industries. These range, for example, from ports handling ammonia or ammonia powered vessels to ship owners, operators and crews through to companies developing additive chemistries and lubricants.

Despite the complexity of the challenges, all key parties involved in making the adoption of ammonia as a marine fuel a reality have chosen to tackle the issues head on. For example, lubricant manufacturers and additive suppliers across the globe, including Infineum, are already working to formulate lubricants to help address the challenges of using ammonia to power marine engines.

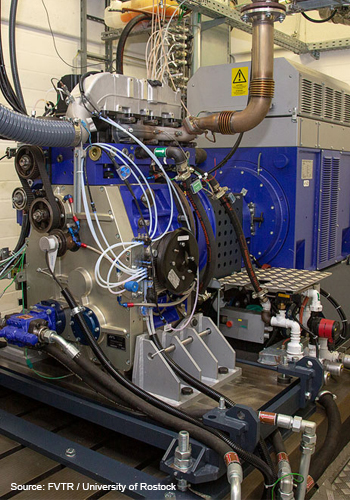

Engine testing on multiple platforms with various third parties has enabled us to establish no harms testing for ammonia and given a rapid understanding of the impacts of the use of up to 95% ammonia on the lubricant

Engine testing on multiple platforms with various third parties has enabled us to establish no harms testing for ammonia and given a rapid understanding of the impacts of the use of up to 95% ammonia on the lubricantAt Infineum, one of our first steps has been to work collaboratively with various third party testing laboratories and expert organisations in multiple engine testing facilities using both pure ammonia and ammonia/hydrogen blends. This work has been very successful in enabling us to gain key knowledge regarding safe ammonia handling practices and to quickly establish no harms test methods. In addition, multiple engine tests have given us a rapid understanding of lubricant phenomena and the ability to focus on areas of most challenge or predicted concern.

Engine testing involving ammonia combustion is crucial as it allows the effects of combustion by-products on the lubricant to be studied. Our findings, from a few hours of operation during ammonia engine testing, revealed that the efficiency of ammonia combustion greatly influences the lubricant. This underscores the fact that considerations of ammonia combustion are indispensable for an ammonia-powered vessel to operate at peak performance, hinting at potential challenges in maintaining optimal lubrication.

More engine test data is needed to further refine and develop the most compatible lubricant additives for these next generation engine platforms.

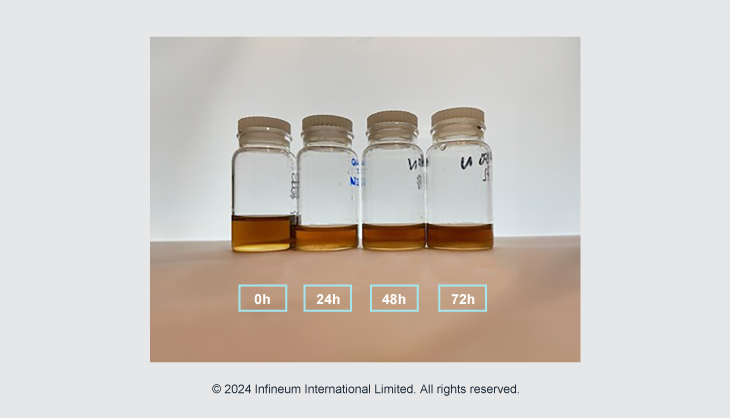

Infineum has implemented customised safety protocols and experimental set ups that enable us to explore the compatibility of our additives with ammonia. Studies on individual additives with ammonia suggest possible incompatibility, which could lead to increased deposit formation and wear. However, under initial observations, minimal changes were noted when a fully formulated marine lubricant was subjected to the same conditions. The latter results suggest that Infineum additives, working together in the lubricant, demonstrate acceptable compatibility with ammonia in controlled laboratory conditions. These learnings are also proving to be helpful in applying knowledge to system oils, which are potentially going to be exposed to ammonia.

Infineum marine lubricant product shows no physical or chemical changes when exposed to ammonia at elevated temperature for up to 72 hours

Infineum marine lubricant product shows no physical or chemical changes when exposed to ammonia at elevated temperature for up to 72 hours

In the long run, only field testing or formal two-stroke engine testing will confirm these phenomena, and Infineum is ready to move into this next phase of testing.

Subjecting additives to ammonia in a laboratory setting provides an in-depth mechanistic understanding of our chemistries. While it is challenging to perfectly replicate the exposure of a lubricant to an engine environment, these engine tests are crucial. They serve as the foundation for future learning and the development of innovative solutions in the field of ammonia combustion engines.

Infineum believes it is important to be robust and thorough in assessing the suitability of any lubricant technology when crossing over knowledge to new fuels such as ammonia.

The initial knowledge gained from both these bench and engine tests highlight key areas of concern, but the challenges are yet to be fully understood and resolved. More work is needed to fully understand the requirements for lubricants used in ammonia-powered vessels. Nevertheless, the key learnings, along with our approach to ammonia safety, have been shared with OEMs and other industry partners to help provide valuable insights.

Given the recent announcements from WinGD and MAN ES on the rapid progress of the development of large two-stroke ammonia ship engines, the reality of ammonia-powered vessels operating at sea is getting closer. Infineum is fully committed to ensuring that suitable lubricants are ready to support the introduction of ammonia-powered vessels to the global maritime market.

Sign up to receive monthly updates via email