Commercial vehicles

What’s driving Daimler Truck?

16 April 2024

Please note this article was published in September 2013 and the facts and opinions expressed may no longer be valid.

01 September 2013

Todays lubricants must deliver fuel economy benefits and excellent wear protection

To play their part in improving vehicle fuel economy performance today’s lubricants are formulated at lower and lower viscosities. Jai Bansal, Global Engine Lubricant Technology Advisor, talks about the research undertaken by Infineum on the linkage between low viscosity oils and engine wear.

There have been so many papers published on the subject that by now the industry is fully aware that one way to deliver fuel economy (FE) is to lower the viscosity of engine lubricants.

However, the use of these low viscosity oils raises the possibility of increased engine wear – which means research into fuel economy really morphs into research into wear prevention.

The work undertaken by Infineum over the past six years, some of which has featured in previous Insight features, has demonstrated that viscosity reduction is the most important lubricant formulation lever for achieving fuel economy gains.

Choice of viscosity modifier is very important to the fuel economy performance of a lubricant

We have already demonstrated that the way this is achieved heavily influences the size of the prize. Oils containing viscosity modifiers for example deliver significantly higher FE than those without, even when formulated to identical viscosities, and the type and quantity of viscosity modifier also play a significant role.

In addition, drive cycle greatly affects lubricant derived FE. For example, an oil formulated to 2.2 cP HTHS (high temperature high shear) viscosity has been shown to deliver around 2% FE relative to an SAE 15W-40 oil in line haul operation. The same oil in low speed/load conditions delivered roughly 3% FE gains, and over 12% FE in idling mode.

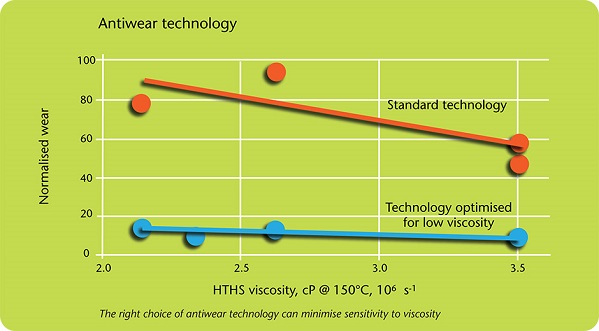

We have also learned that reducing lubricant viscosity to improve fuel economy performance is not without consequence. As viscosity is lowered, the oil film thickness is reduced and its ability to keep the engine contact surfaces sufficiently apart from each other decreases.

This can lead to accelerated wear, and it really makes little sense to trade engine durability for fuel economy gains. Extensive engine testing with low viscosity lubricants has convinced us that the wear protection requirements of low viscosity oils are very different from those of conventional viscosity oils.

Fuel efficiency at the expense of engine durability makes no sense

In one test on a standard heavy-duty diesel engine, a 2.6 HTHS viscosity oil formulated with a conventional API CJ-4 additive technology resulted in catastrophic engine failure.

While the exact sequence of events leading to the engine failure could not be established, it is believed that excessive wear in one of the crank assembly components resulted in seizure of the crank shaft, causing it to break and exit from one side of the engine body. However, when the same engine test was run using SAE 15W-40 formulated with the same additive technology an excellent passing performance was observed.

This work made it clear that development of low viscosity lubricants had to be approached with extraordinary care to ensure uncompromised protection against engine wear. A fundamental understanding of the wear processes taking place on various contacting surfaces was seen as a critical enabler for the success of this venture.

The first step was to identify the regions of engine operation and oil formulation where the potential for engine wear is highest.

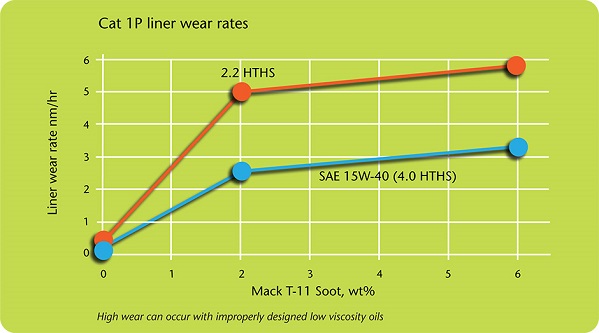

Fundamental research using advanced radioactive tracer technology enabled Infineum to examine the effects that engine drive cycle, lubricant formulation and in-service ageing of lubricants have on the wear of critical engine components. The study revealed that, amongst other things, soot plays an extremely important role in wear in low viscosity environments.

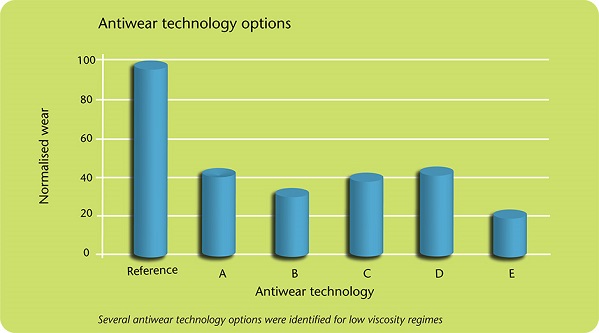

These insights led Infineum to develop customised bench rigs to study the tribochemical processes taking place in different types of contacts in the engine. The rigs were also used to help screen a variety of new antiwear technologies.

At the same time, because soot has been identified as a significant influencer on the amount of wear, we entered into collaborations with leading tribology researchers in the academic world to improve our fundamental understanding of the nature of soot and how it behaves in confined spaces.

Infineum has used the findings from the bench tests and specialist research to develop proprietary engine rigs to validate the technology options in conditions closer to those found in the real world. Further experimentation using these rigs has led to the identification of several useful antiwear technology options, which can minimise the wear sensitivity of low viscosity fluids.

The knowledge that Infineum has gained from its research into FE and wear over the past six years has been put into the development of a leading edge ultra low viscosity FE technology platform. Insight will report on this development in the next article in this fuel economy series.

As OEMs push for improved fuel economy to meet legislative targets, and industry specifications establish formal categories for fuel efficient lubricants, you can be sure that fuel economy will continue to dominate lubricant formulation research.

Infineum aims to use the data from its research to allay potential concerns regarding the use of very low viscosity lubricants, to educate end users about the benefits of advanced FE lubricants and to ensure our products stay ahead of industry needs.

Sign up to receive monthly updates via email