Small Engines

New JASO T903 motorcycle specification

04 July 2023

15 September 2020

Exploring the drivers that are impacting the latest four-stroke engine oil formulations

In many of the world’s developing markets the demand for smaller displacement workhorse two-wheelers is growing while, at the same time, emissions regulations are tightening. These are just two of the factors that are driving the development of new engine oils for this market segment. Rio de Janeiro based Leandro Benvenutti, Infineum Specialties Market Manager & OEM Advisor, talks to Insight about these trends and the influence they are having on Infineum four-stroke motorbike formulations.

The vast majority of today’s motorcycles and motorcycle sales are in Asia, with the combined new sales in China and India reaching 36 million in 2019. While sales in Brazil were only just above one million in 2019, this was enough for the country to rank 8th in the world and to make it the largest two-wheeler market outside of Asia. In Leandro’s view, Brazil is an important, expressive and very interesting motorcycle market, but one where he sees an important role to educate end users on the lubrication requirements of their machines.

A motorcycle engine has twice the specific power of a car engine and has half the volume of oil in the crankcase, creating very severe conditions for the lubricant.

"Motorcycles are quite different in terms of their lubrication needs when compared to a car," Leandro explains. "They run on average at 8,000 rpm, while the car engine runs at 4,000 rpm. A key difference in their lubrication is that a motorcycle lubricant must not only protect the engine but also the transmission of a manual motorcycle, the transmission gears, the clutch and its coupling, because everything is bathed in the same lubricant. Today’s passenger car lubricants are being formulated to lower and lower viscosities and need to meet performance requirements that can be antagonistic in the motorcycle transmission and clutch. That is why a motorcycle formulation must be tailored to not only protect the engine but also to avoid wear and pitting of the transmission and to supply sufficient friction in order to engage the clutch discs. These specific requirements are leading additive companies to develop specific packages that deliver the required performance, while also meeting these differentiated and sometimes conflicting requirements.”

Lubricant specifications have been introduced to ensure motorcycle oils deliver the required level of protection to all of the essential areas. In Brazil, for example, a motorcycle lubricant must meet both the current JASO standard and API quality level.

“The API quality level ensures the oil will deliver sufficient engine protection, while the JASO specification focuses mainly on clutch friction,” Leandro explains. “JASO has three intuitive tests to identify the performance of the lubricant in relation to friction, which people need to understand to ensure they can evaluate the lubricant correctly from the label. First the Dynamic Friction Index (DFI) measures the friction when two surfaces slide over each other, which occurs for example when the clutch is engaged, creating a dynamic frictional force between two moving disks. Then we have the Static Friction Test, where a force is applied to stationary surfaces so that one starts to move in relation to the other, which occurs, for example, when the clutch is stopped and torque is applied until it starts to slip. In both of these tests the best performing lubricants will have high results. The third is called the Stop Time index (STI), which assesses how fast the clutch is engaged.”

The JASO specification is now a little complex to understand, with different classification levels required for different applications. However, as Leandro explains, this has evolved.

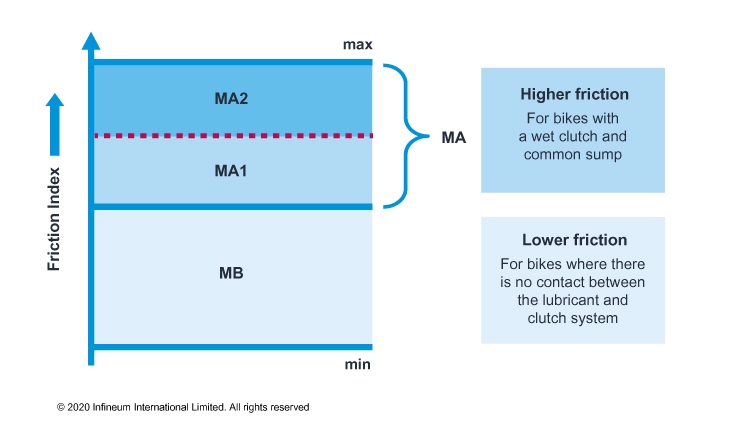

“Initially, JASO had only two levels of classification: MA and MB. JASO established a friction limit for the three tests and everything above the limit was considered MA and everything below MB. Bikes with a wet clutch, where the lubricant is in contact with the clutch, need MA oils to prevent clutch slippage. In some bikes, for example scooters that use a continuously variable transmission, where there is no contact between the lubricant and the clutch system, it is better to use a lower friction JASO MB lubricant for improved fuel economy.”

However, over time, it became apparent that MA lubricants could have differences between them, some with a much higher friction test result than others. This prompted JASO to create MA1 and MA2 categories – MA2 being at the top of the classification and MA1 lying below MA2 but above MB.

“I think this probably causes some confusion for consumers. What I can imagine is that the motorcycle owner looks at their manual and sees that the automaker recommends JASO MA. When they arrive at the store to buy the lubricant they could find JASO MA2 and may be unsure if this is the right oil. Clearly the answer is yes – they could and should use the MA2 oil, it will have a better result in terms of clutch hitch performance. But, because of these doubts, manufacturers, who can classify their lubricant as MA2, may prefer to put MA on the label to avoid doubt and ensure they get a sale, so it is clearly important that consumers know the difference.”

The move to lower viscosity engine lubricants for fuel economy improvement is one trend that end users in Brazil had been somewhat reluctant to embrace. While, to a large extent this has been overcome in the local passenger car market, Leandro suggests that this acceptance is taking a little longer for motorcycle users.

“In Brazil, the market for lower viscosity passenger car lubricants is growing with SAE 5W-30 now common and people already talking about the development of new lubricants with very low SAE 0W-16 or 0W-8 viscosity grades. It is unclear why it is taking a little longer for bikes, but I imagine one thing that is worrying motorcycle owners is the fact that the lubricant has to lubricate the gears and they may feel a very low viscosity lubricant could create a problem here. However, if we look at a car gearbox lubricant, it meets the SAE J306 viscosity standard, which is not the same standard that defines the viscosity of the engine oil, which is SAE J300. The scale is different, so when we look at the viscosity of a transmission oil, we see that many manufacturers use SAE 85W oil, because it is a large number, it must be a very high viscosity, but it is not. An SAE 85W oil starts in the 11 cSt viscosity range, which is the same viscosity range as a SAE 5W-30, which goes from 9.3 to 12.5 cSt. So a SAE 5W-30 oil or 10W-30 oil has the same kinematic viscosity at 100 degrees as a passenger car transmission oil, so that shouldn't be a concern or demerit for a low viscosity motorcycle oil, which should give reassurance."

End users can be confident in their oil if they follow the advice of the manufacturer in their owner manual.

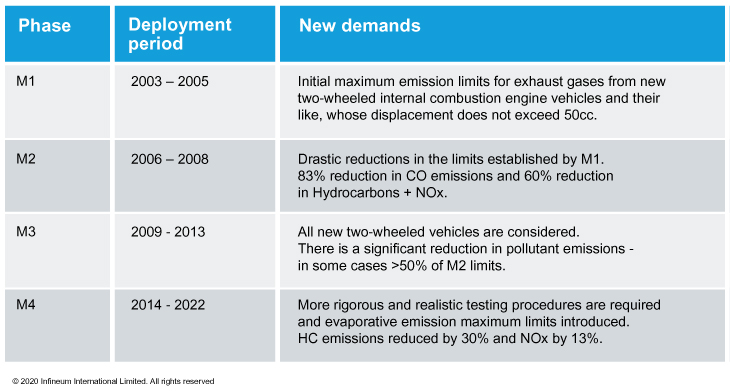

Across the globe, legislators are introducing and tightening emissions limits from vehicles and in more and more cases these regulations include motorcycles. In Brazil, the Air Pollution Control Program by Motorcycle and Similar Vehicles or PROMOT has been regulating emissions since 2002 and will be revised on 1 January 2023, which Leandro expects to bring change to motorcycle hardware.

“Back in 2003, motorcycles had no aftertreatment system and a bike was capable of emitting 20 times more pollutants than a car – a really unsustainable situation, particularly in large urban centres. PROMOT emissions regulations came into force in 2002 and have evolved through phases M1, M2, M3 to today’s PROMOT M4, with M5 already approved for 2023.”

“In PROMOT M5,” he continues, “along with the reduction in emissions, there will also be a requirement for onboard diagnostics, which are embedded electronics systems that control several motorcycle systems. In the first phase, OBD 1 that do not control emissions will apply. But, from 2025, OBD 2, which will have a probe system that measures exhaust gas and oxygen concentration, will be required to ensure the catalyst is working effectively.”

But it is not only the hardware that will be impacted by these new regulations, Leandro expects lubricant formulations will also change significantly.

“The lubricant has chemical components, such as sulphur, phosphorus and ash, that can affect the catalyst. Whenever an emissions standard is tightened, the catalysts have to be more efficient and are therefore even less tolerant to these chemicals, affecting the formulation of the lubricant. Phosphorus, for example, is a delicate point because JASO has a minimum phosphorus limit to ensure the protection of the gears while API, that controls the quality of the engine lubricant, has a maximum allowed level of phosphorus."

With the upcoming emissions standards for two-wheelers, the industry is working very hard to develop technologies with less phosphorus that will guarantee performance in all the critical lubrication areas.

In Brazil, there is some evidence that end users ‘upgrade’ the formulation of their finished motorcycle oil by adding an additional supplement, such as a metal conditioner. But, as Leandro explains, this practice really is unnecessary and could even be harmful.

“During its development a motorcycle lubricant goes through several stages before gaining approval. A battery of tests are carried out by API, JASO, ACEA and OEMs, among others, and if any failures occur the formulation is redesigned and the testing is repeated. Sometimes one issue is resolved only for another to arise elsewhere and the process starts again. This is because the formulation of a lubricant is a very complex balance, due to the many interactions between additives that can influence the performance of each other. This means that completing the formulation is a very expensive and time consuming job. But, investing resources in the formulation and approval process ensures that the resulting lubricant is a balanced formula that has passed all the required tests."

The chance of improving the performance of an approved oil by adding a supplementary additive is very small because, whenever the balance is changed, testing is required to make sure that no problems have arisen.

Leandro gives an example: "If a supplementary additive is added that the consumer believes can reduce wear, can they be sure it will not cause a deposit problem or damage a seal? There is no way to quantify the benefits of these supplements and, in my view, the consumer is really taking a big risk when using them.”

Infineum works at different performance levels and has packages with a high performance level that, for example, allow the formulation of low viscosity SAE 5W-30 lubricants, some packages that deliver an intermediate quality while others offer a basic quality. Even the basic Infineum quality level provides everything the bike needs, while a top tier lubricant will bring a greater benefit to the customer. Unfortunately there are some products on the market that are low cost but also very low quality. Consumers in Brazil can consult the ANP website here to access reports on existing lubricant quality issues in the market.

With very significant differences, in terms of the types of lubricant, SAE viscosity grades and quality levels, end users can find motorcycle lubricant selection challenging. Here Leandro has some very simple advice to help consumers choose the best oil for their bike.

“There is no magic in lubricant formulation – it’s all about investing in extensive testing to prove performance. If consumers follow the manufacturers’ guidance in the owner manual on lubricant quality level and drain interval, buy a well formulated lubricant, designed for motorcycle use, from a reputable and suitable company there is no need to add a supplementary additive. There is nothing else to it, these simple actions will guarantee the lubricant will continue to deliver sufficient protection to that specific motorcycle throughout its lifetime in the engine.”

Sign up to receive monthly updates via email