Fuels

Driving hydrogen forward

21 January 2025

28 September 2021

Infineum marine fuel additives offer improved environmental performance and contribute to sustainability goals

Growing concerns about climate change and the quality of our air, combined with geopolitics and societal pressure are some of the key drivers that are increasing the pace at which the world is taking action to cut emissions. Rob Ashton, Infineum Marine Fuel Additive Global Market Manager, looks at the ways in which Infineum additives are helping its marine fuels customers as they work to meet sustainability targets by providing products that deliver environmental, social and economic benefits.

The transportation industries are working hard to reduce emissions. Efforts are being made to cut greenhouse gas emissions by reducing fossil fuel consumption and to reduce all other combustion sourced emissions such as sulphur, nitrogenous oxides (NOx) and particulate matter.

Whilst low or even no-carbon fuels are recognised as the desirable end point, it is fundamentally clear that fossil-based oil, gas and coal will continue to be the dominant energy sources for decades to come.

In the quest for a more sustainable future, the marine industry has been active, mapping out its own pathways.

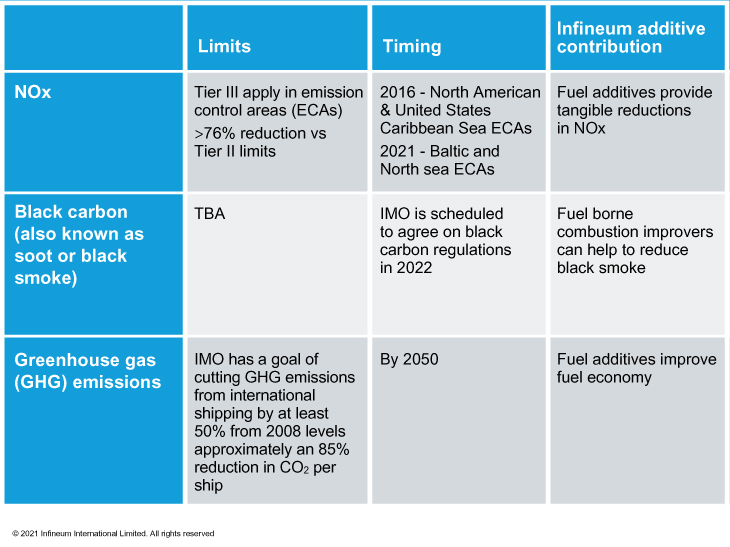

Having successfully implemented IMO 2020, where the fuel sulphur level was cut from <3.5% to <0.5% from 1 January 2020, we have seen that the industry is prepared and able to contribute towards a more sustainable future with significant steps. However, it does not stop there and the next targets for reduction include:

What is clear is that all participants in the marine value chain will need to contribute in order to accelerate the pace of emissions reduction. In April 2021, Infineum published its first Sustainability Report, which details our commitments to creating a sustainable future through innovative chemistry – click here to read the full report.

A core element of the Infineum sustainability strategy is to reduce our impact on the climate and resources through our products.

The rest of this article gives an overview of how the Infineum marine fuel additive portfolio can contribute.

Infineum asphaltene management additives were developed in the lead up to IMO 2020. They were introduced in anticipation that sedimentation issues would be more prevalent as a consequence of blending low sulphur (and directionally more paraffinic) cutter stocks with high sulphur fuel oil to produce a 0.5% sulphur very low sulphur fuel oil (VLSFO). These potent additives are effective at preventing asphaltenes from separating out of the fuel medium as waste sludge over a fuel’s lifetime from fuel production/blending, through the supply chain, onboard storage to point of injection where the fuel is burned. VLSFOs are less stable than their high sulphur fuel oil (HSFO) counterparts and can experience instability at any point during the fuel’s lifetime, particularly when it is stressed with heat or co-mingled with other fuels in the supply chain. ISO8217 has a provision to minimise total sediment by hot filtration to <0.1 mass % at point of sale. However, there are many reported cases of vessels experiencing excessive sediment/sludging shortly after bunkering. Sediment drop out can occur in storage tanks and at the separator/purifier and can represent a significant loss in fuel economy. In addition to the fuel economy penalty, the waste sludge will also require off-loading and processing incurring further cost and energy penalty.

The use of Infineum asphaltene management additives maximises the quantity of useable fuel (in addition to being able to recover many unusable fuels) and minimises waste sludge thus contributing to a more sustainable ship operation.

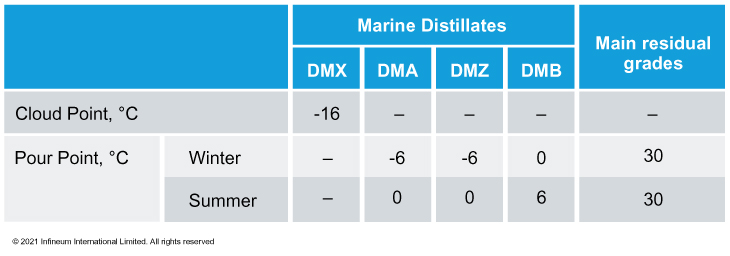

Infineum has a long history in the development of high performance wax management additives for hydrocarbon streams. In marine fuels, ISO 8217 recognises the importance and challenges associated with wax and has traditionally addressed this through pour point specifications in both distillate and residual fuels:

In the 2017 revision of ISO 8217 requirements to report cloud point and CFPP of marine distillates were also included to help end users to assess cold flow additive usage requirements. VLSFOs are widely recognised as having lower viscosities and higher pour points than the HFO counterparts, which has resulted in operational difficulties in handling the fuel. There is a fine balance between maintaining the fuel at the correct temperature to ensure that it flows (above pour point) as well as minimising wax deposition in stagnant areas of storage tanks and ensuring that the operational viscosity at point of injection is not compromised (ca 15 cSt).

Infineum wax management additives are extremely effective in helping to manage this balance. They do this by reducing the pour point of the fuel, thus enabling fuel flow to be maintained at a temperature that does not adversely affect operations, whilst ensuring there is no solid wax build up in the supply chain. The net result is that these additives can decrease the required fuel temperature to maintain fuel flow in the fuel supply system thus reducing the requirement for extra heat from auxiliary boilers. This in turn contributes further to reducing the carbon footprint as well as enabling the wax (a high-quality combustion component) to be transported through to the point of combustion, thus optimising the overall combustion efficiency of the fuel. In addition to this the ship does not expend energy carrying dead weight in the form of solid wax in the fuel tanks, which also minimises fuel storage capacity.

Infineum wax management additives enable wax to be transported through to the point of combustion thus optimising the overall combustion efficiency of the fuel.

Given the drive towards GHG reduction and improved air quality, Infineum has invested in the development of a combustion improver fuel additive, which is close to completion. This has been designed to deliver statistically significant fuel economy and emissions reduction benefits. During the market assessment process, we were made aware of the scepticism that has historically existed with fuel borne combustion improvers. This prompted a rigorous scientific engine test program to explore and understand the additive impact at critical operating points in marine engines. ISO 8217 addresses fuel combustion quality through CCAI (Calculated Carbon Aromaticity Index), which as the name alludes to is a calculation using the density and the kinematic viscosity of the fuel. It is recognised, with the introduction of VLSFOs, that CCAI may not give an accurate reflection of a fuel’s combustion quality due to increased utilisation of cracked cutter stock into the fuel blending pool.

The Infineum combustion improver additive has been proven to deliver fuel economy and emissions benefits, which will give tangible sustainability benefits to ship operators.

In addition to fuel economy and emissions benefits the additive delivers the capability to upgrade lower quality fuels for trouble-free operation across the marine fuel oil spectrum (HSFO and VLSFO).

Infineum has a broad range of lubricity improvers that are all derived from natural, sustainable sources such as tall oil, rapeseed and other common oleic acids. Most Infineum products have 100% active ingredients and are supplied via multiple supply points thus minimising the carbon footprint between the supply point and the end customer. Lubricity additives offer extra wear protection when lower viscosity VLSFO and marine gas oil grades are used onboard. Excessive wear in fuel injection components can compromise injection performance, which in turn can negatively affect combustion and emissions performance. Optimising emissions output is one of the key challenges that the industry is seeking to address to improve air quality.

The use of Infineum’s robust lubricity improver range will help to maintain hardware in optimum condition to facilitate emissions output optimisation.

As the world works to decarbonise and reduce emissions, Infineum will play an important role in delivering new products that form the lifeblood of global trade and transportation. Our commitment to creating a sustainable future through innovative chemistry means we are focused on continually improving the environmental performance of our products.

Sign up to receive monthly updates via email