Base stocks

Unlocking the potential of re-refined base oils

08 April 2025

13 August 2019

How building sustainability into the core of business strategy is driving success

Following his presentation at the ICIS World Base Oils Conference, Mika Kettunen, Technical Product Manager at Neste, talks to Insight about why sustainability is important in the fuels and lubricants industries and how, in his view, working to make the planet a better place for future generations can be combined with creating new sources of revenue.

Mika Kettunen at the 23rd ICIS World Base Oils Conference

Mika Kettunen at the 23rd ICIS World Base Oils ConferenceIn recent years, Global Renewable & Oil Products and Marketing & Services organisation, Neste, has been actively integrating sustainability into its business strategy and making sustainable development a key part of its business plans. As a result, over the past ten years, Neste says that it has transformed from a regional oil refining company into a global leader in renewable fuels and one of the most sustainable companies in the world.

“In 2018 our customers reduced their greenhouse gas emissions by 7.9 Mt with our renewable products - equivalent to the annual emissions of 3 million cars.”

With the organisation placed in the top three on the Global 100 list of the world's most sustainable companies for the second time in 2018, Insight wanted to understand the drivers for prioritising sustainability in the organisation’s objectives. “Our industry has traditionally been based on utilising fossil fuel that is not going to renew itself,” Mika explains. “Human activity, particularly the burning of fossil fuels, is resulting in a rising level of CO2 in the atmosphere and an increase in average annual temperatures. This is expected to have significant consequences, including the loss of animal and plant biodiversity, an increase in extreme weather phenomenon and a rise in sea levels as glaciers and sea ice melt. This is worrying now, but will be an even bigger issue in the future if we do not limit global warming to 1.5oC above pre-industrial levels; we have already passed 1oC at the current warming rate.”

“The state of our planet calls for urgent action – in response we are making responsible choices every day to create a healthier planet for our children.”

This drive for sustainability is something the organisation hopes others in the industry will urgently adopt. As Mika explains, “Sustainable development generally addresses three key priorities. It recognises that businesses need to make a profit to ensure economic growth, but in doing so their activities need to increase equality and take care of human rights in order to help increase social well being in the world. At the same time, the environment must not be compromised by business activity; especially where natural resources are used as raw materials to gain economic growth.”

“Sustainable development means meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

Mika says that transportation has a key role to play here since it is estimated that about 20% of global GHG emissions come from this source. “Although the demand for fuel from road transportation is 50 times greater than the demand for lubricants, which puts lubricant suppliers at a good starting point, it is estimated that 30% of global energy produced is lost in friction. And, as the EU takes action towards a climate neutral economy by 2050, we are seeing GHG emissions reductions targets and legislation that aim to cut the CO2 emissions from cars and trucks. This activity puts pressure on all the related industries - including the lubricant and base oils businesses. It is essential that we turn our limited carbon burden into even lower greenhouse gas emissions by enabling greater fuel savings in the transportation sector.”

The fuels and lubricant industries have a strong track record of developing solutions to meet environmental challenges, but what new issues are associated with climate change? “In my view,” Mika explains, “the ability of our industry to create solutions that respond to climate change relies on a good understanding of the impact these products have on sustainability and on the accuracy of emissions projections. Life cycle assessment (LCA), which provides quantitative results in terms of the CO2 emission equivalent per kg of product (kg CO2e/kg product), is a useful tool that can be used to assess the carbon footprint of a product system. However, despite the fact that there are general and specific standards for conducting LCA analyses, it remains difficult to compare results across sectors. Currently, there is a lack of specific LCA rules that could be adopted by the lubricants industry.”

“The real challenge in adopting LCA for lubricants is establishing commonly accepted system boundaries for the breadth of potential data sources. “

Mika says that, because there are so many different options, the standard measurement of LCA is challenging. But, he believes it would be beneficial for the industry to agree on such methods as it starts on a path to sustainability. “In my view, by adopting a ‘cradle to grave’ approach it is possible to establish the total lifecycle of lubricant oils. This comprehensive methodology covers every step of production, use and disposal, including raw material sourcing, transportation and packaging. It not only provides a clear indication of the lifecycle stage(s) during which the most substantial GHG emissions are reported but also where there is the most room for further GHG emissions reduction.

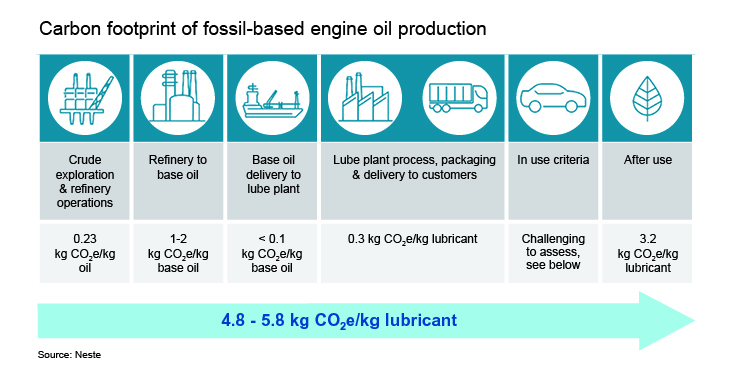

In ‘cradle to grave’ analysis, the carbon footprint of lubricant production has been calculated at between 4.8 – 5.8 kg CO2e/kg lubricant although, as shown below, not all production steps contribute equally.

Assessment of the carbon footprint throughout the lifecycle of a lubricant

Neste has taken the example of a European passenger car on a 30,000 km drive to assess the ‘in use’ contribution of a lubricant. “Assuming that with a regular lubricant the average fuel consumption was 6 litres/100 km and the oil drain interval 15,000 km. In this case, for the entire journey, 1,800 litres of fuel and 10 litres of oil were used. The use of a higher quality oil, optimised for fuel economy (delivering 1% improvement) and with double the lifetime of the regular oil, thus reducing one oil fill, resulted in 18 kg CO2e /kg extended drain oil emissions savings.”

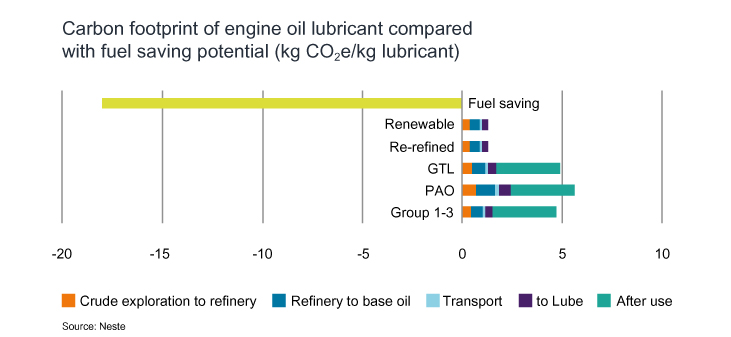

The use of high quality base oil and lubricant products can give the greatest potential for GHG emissions improvements, usually via energy or fuel savings

The use of high quality base oil and lubricant products can give the greatest potential for GHG emissions improvements, usually via energy or fuel savings

“If one car and a single oil change can offer this level of GHG savings, imagine the possibilities if the approach was applied to hundreds, thousands or millions of cars.”

“The thing I want people to take away from these findings,” stresses Mika, “is that we must not miss the carbon savings ‘in use’ improvements can give. In my view, we should be making more use of renewable raw materials to create top tier base oils that enable the formulation of lubricants that can deliver longer oil drains and fuel economy improvements. However, we should also address the second biggest target, which is the 3.2 kg CO2e/kg lubricant that is generated from the incineration of waste oil - that would also have a big impact on climate change.”

It is very likely that one of the first questions that any business will ask, as it looks to improve sustainability, is ‘how much is it going to cost?’ However, Neste has a different approach here and suggests that the question should be ‘how can my business profit from investing in sustainability?’

“In our view, instead of avoiding costs our industry could invest in new technology to explore innovative ways to turn sustainability into new profit.”

Mika puts forward a very strong example to demonstrate the power of this approach. “In 2012, although the majority of our operating profit came from the sale of refinery oil products, Neste had entered into renewable fuels. We did this by establishing a new Renewable Products Business Unit, which initially required investments in areas including technology development, patents, and plant construction. Our move into renewable fuels has transformed our refinery and its profit base and in 2018 Renewable Products delivered almost €1 billion in profit.”

Renewable products have created a new business opportunity for Neste

But, as Mika explains, the advantages do not stop at improved profit. “As previously mentioned, in 2018, our renewable products and solutions helped reduce our customers’ GHG emissions by almost 8 million tons, which is equivalent to the annual carbon footprint of 1.2 million average EU citizens. And, our aspirations do not stop there. As part of our goal of becoming a global leader in renewable and circular solutions we have an ambitions target of reducing our customers’ GHG emissions every year by at least 20 million tons CO2 equivalent by 2030.”

While the return on investment and reduction in GHG emissions are impressive, Mika suggests there are other learnings that can be taken away from Neste’s move to renewables. “There are no quick wins for such bold initiatives and at first the objectives can seem unachievable, which means commitment and faith in positive outcomes are vital. I know that an industry-wide change does not happen overnight, but I believe that making the planet a better place for future generations is possible, and it can be combined with creating new sources of revenue. Now is the time to unite our industry in this vital cause.”

Sign up to receive monthly updates via email