Videos

Marine fuels sludge management

28 June 2024

16 April 2024

In the commercial vehicle segment, the use of hydrogen internal combustion engine technology is gaining ground as manufacturers and operators look for near-zero emissions options that can meet their specific requirements.

At Infineum, our R&D programmes are committed to producing advanced additive technologies to help overcome the challenges hydrogen combustion poses. We believe hydrogen is the fuel of the future for commercial transport and off-road equipment – watch our video to find out why.

With an increasing focus on net zero globally, manufacturers and operators are looking for new ways to achieve the demanding challenge of near zero emissions quickly.

Battery electric vehicles (BEVs) are becoming the popular choice for consumer automotive solutions, but multiple barriers remain for large scale adoption of battery technology for commercial vehicles, including purchase price, total cost of ownership, recharging time and utilisation modifications.

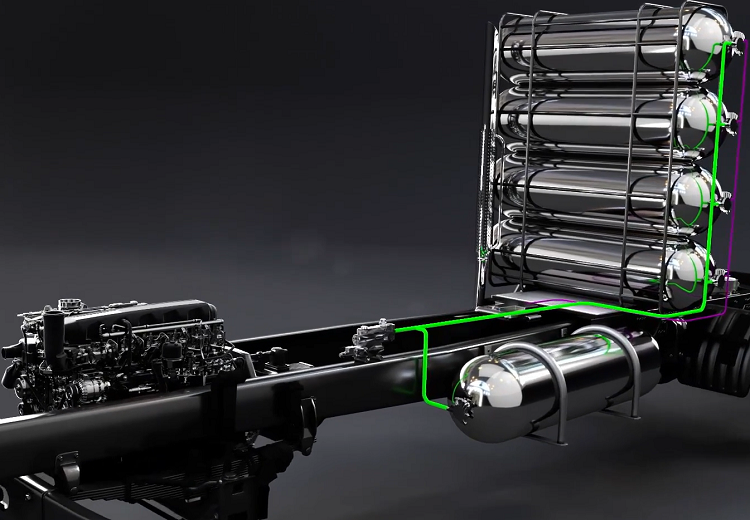

This is where hydrogen internal combustion engine technology comes into its own, meeting power and efficiency requirements under high loads, with near zero emissions.

Hydrogen internal combustion engines are very similar in design and configuration to traditional gasoline, diesel and natural gas engines.

This means the manufacturing infrastructure, supply chains and skillsets are already available in the industry to rapidly transition to a low carbon propulsion.

As internal combustion engines have been ubiquitous for many years, and are supported by extensive service networks, for manufacturers and fleet operators, the switch to hydrogen engine drivetrains involves familiar parts and technology.

At Infineum, we believe hydrogen is the fuel of the future for commercial transport and off-road equipment, offering good range of around 700 miles per tank, fast refuelling, excellent engine durability, and of course near zero carbon emissions.

This is supported by major OEMs in the space already investing heavily in prototyping new vehicles and equipment, with one off-road equipment manufacturer investing over £100mn in a hydrogen ICE development programme.

Infineum’s own research and development programmes are committed to producing advanced additive technologies to overcome the challenges hydrogen combustion poses to safe and trouble-free operation of zero emission vehicles.

One of the major challenges are combustion anomalies, in particular pre-ignition.

Pre-ignition is a greater problem for H2-ICE engines than engines running traditional fuels, due to the low ignition energy, wide flammability range and rapidity of combustion of hydrogen fuel.

Pre-ignition can cause damage to pistons and head gaskets, leading to expensive repairs. however even in robust heavy duty engines where damage may be less severe, issues with combustion can still have significant effects on fuel economy and reduce engine power.

Alongside hardware adaptions to mitigate the risk of pre-ignition, the lubricant also plays a key role in managing this challenge by careful formulation to ensure that oil droplets in the combustion chamber do not initiate pre-ignition.

Deposit derived hot-spots in the combustion chamber also initiate pre-ignition. This means the keep-clean performance of the engine lubricant is important to minimising the occurrence of pre-ignition.

Protecting engine surfaces and maintaining a clean combustion environment is the primary role of the engine lubricant, however new considerations in lubricant properties need to be considered for use in hydrogen engines.

For example, the primary emission from hydrogen combustion is water, which is what makes it such an environmentally-attractive future fuel, with vehicles running on hydrogen will only emit steam when equipped with suitable NOx management technologies.

Water, however, causes corrosion, sludge and engine damage through freezing if not managed correctly.

So it’s vital that the lubricant is designed to remove the water from the engine’s surfaces, forming a stable and low viscosity emulsion to prevent the water from freezing or corroding metals.

Protecting the engine from high wear cold starts due to the presence of water in the lubricant is a key consideration.

Once the engine is at operating temperature, the oil will regenerate when the water evaporates.

It’s important that the lubricant remains stable through this process, so the additive package should ensure robust stability in the presence of water.

As hydrogen is such a clean fuel, the exhaust aftertreatment system requirements are significantly reduced in hydrogen ICE vehicles.

As with any combustion process, due to the presence of nitrogen in the ambient air, a small amount of NOx is produced.

But hydrogen can burn at much leaner levels, so depending on the fuel/air mix and engine calibration, the levels of NOx produced are significantly lower than traditional gasoline or diesel engines, potentially near zero.

With energy transition at the top of many manufacturers’ and operators’ priority lists, Infineum are investing in the research and development needed to facilitate this shift.

We are ready to work alongside future-looking industry leaders in lubricant suppliers, engine manufacturers, vehicle OEMs and governments to meet our combined objectives of a carbon-free future.

Infineum. Performance you can rely on.

Sign up to receive monthly updates via email