Fuels

Fuel additive sea trials

08 July 2025

25 September 2018

Extreme conditions test cold temperature operability performance

Each year, Infineum conducts field trials on Japan’s north island in extremely harsh conditions. HS Choi, Infineum AP Fuels Technical Expert, talks about the insight that these trials provide into the impact of diesel fuel quality on vehicle operability at extremely low temperatures.

With average minimum temperatures in January and February of around minus 13°C, Asahikawa-city, Hokkaido, Japan is the perfect place for Infineum to validate the performance of its products in real conditions, rather than relying solely on laboratory tests.

Working in co-operation with key OEMs and oil companies from different countries, who also attend the trial, the Infineum Japan Fuels Team starts the tests in below freezing pre-dawn conditions.

The aim is for everyone to gain a better understanding of the operability performance of cold flow improver (CFI) additives, diesel fuels and hardware in these extremely severe conditions. For many it is their first experience of real field issues, and for most it is a sub-zero experience that they never forget.

Field trials are the only way to accurately gauge vehicle

Field trials are the only way to accurately gauge vehicle The real world operability performance of fuels is impacted by a number of factors. These include the fuel’s wax content, how wax crystals form and the way wax precipitates onto the filters. Cold flow laboratory tests are not designed to simulate real world conditions, since such a complex combination of variables is involved. The bench tests typically contained in fuel specifications are designed to offer adequate protection against vehicle cold flow failures under some conditions. However, as vehicle and fuel technology evolves, it is important to understand if the level of protection provided needs to change.

Cold filter plugging point (CFPP) is one of the most common parameters included in fuel specifications and it has been used successfully to indicate if fuels are fit for purpose. In addition, Infineum uses rig simulations as a convenient way to predict which cold flow additives will provide the required level of operability performance under certain conditions.

But, even the cold chamber chassis dynamometer (CCCD) test, which uses a real engine, run under controlled conditions, is unable to fully replicate real world conditions. In our view, field trials are the only way to accurately gauge vehicle cold flow operability and identify any possible future issues that the bench tests may not highlight. The trials in Japan enable Infineum to identify different failure mechanisms and phenomena in test vehicles. The results can then be combined with data from CCCD tests and used to calibrate future rig simulations.

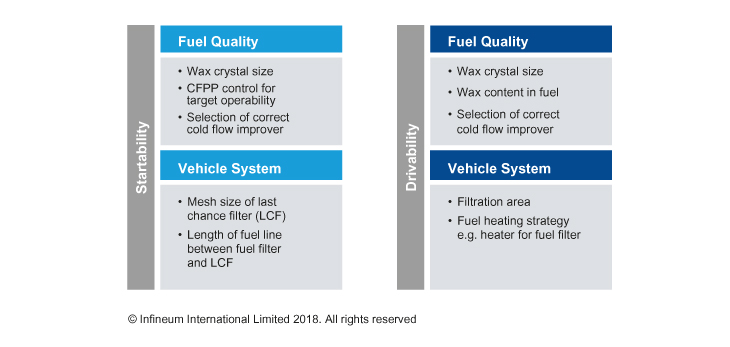

Infineum uses two parameters, ‘startability’ and ‘drivability’, to assess operability performance, both of which are affected by the quality of the fuel and the vehicle system.

The last chance filter (LCF), that protects the high pressure pump, affects startability performance. During periods of vehicle inactivity, for example overnight, wax crystals form in the fuel and are retained in the fuel line. When the engine is started, these crystals can block the LCF. This means that a key vehicle system parameter is the mesh size of the LCF and the length of the fuel line.

Drivability performance is affected by the accumulation of wax formed in the fuel tank on the fuel filter. The filter will be plugged if the wax is not re-melted by the fuel as it is warmed during engine operation. Until early in the 2000s, most vehicles relied solely on the warmth of fuel returning from the engine to the tank to melt the wax. Recent vehicles typically have an electric heater to warm fuel or recirculate the fuel from the engine to the fuel filter, which reduces the probability of filter plugging and improves drivability.

The combination of good CFPP performance and the presence of small wax crystals in the fuel can improve the filter’s tolerance and make the wax easier to re-melt.

To achieve this, refiners need to select the most suitable additives and ensure their fuels meet the appropriate CFPP specification. Cold flow improvers allow the maximum operability performance with a given fuel to be achieved. But, because the filter capacity and filtration area are limited it is also essential to control fuel wax content.

Infineum works with refiners and OEMs to advise on the best fuel characteristics to give optimum operability performance with today’s fuels and vehicles. The Japan winter field trials provide an excellent opportunity to look for the best ways to examine startability and drivability and to assess ways to improve vehicle operability.

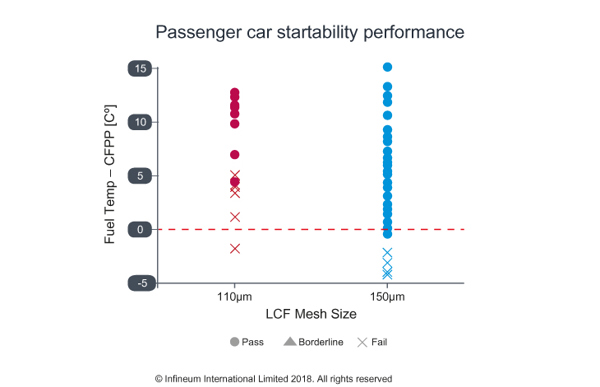

The startability test is used to assess if the engine will continue to run after the first ignition. The charts below show the startability performance of vehicles running on standard Japanese Grade 2 fuel treated with conventional cold flow improvers. The Y-axis indicates the difference between the fuel temperature and CFPP. Where the fuel temperature was above the CFPP the data point is above the red line, which means the data points below the red line indicate the fuel temperature was lower than the CFPP – the lower the point at which borderline or fail results start appearing, the better the result.

The startability performance of two passenger cars with almost equal fuel line length between fuel filter and LCF and retained volumes of ~20cc but with different LCF mesh size was assessed. The test fuels typically have needle-shaped wax crystals of 100-150 microns at the CFPP temperature.

Unsurprisingly, the vehicle equipped with the larger mesh LCF performed better in startability tests than the vehicle with the finer mesh - which failed the test above the CFPP temperature.

The results demonstrate how important it is to use appropriate wax crystal modifiers and cold flow improvers to control CFPP in the refinery.

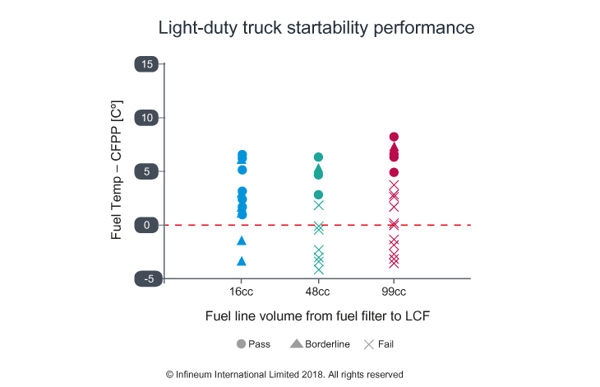

The startability performance of three light-duty trucks, all using the same LCF, was also evaluated.

It is evident from the results that longer fuel lines between the two filters (main filter and last chance filter) have a negative impact on startability performance. As high pressure common-rail fuel systems become even more precise, the role of last chance filters is expected to increase. Since engine ignition can be achieved with the fuel filled in the line and the wax inside this fuel can be crystalised and coagulated overnight at a slow cooling rate, it would be more difficult to pass the last chance filter if there is a large amount of line fuel.

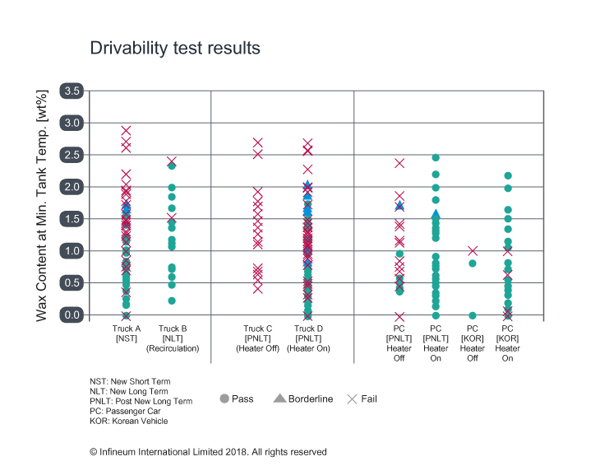

The drivability test assesses if the vehicle can continue to run at 50 km/hr for the duration of the test. Drivability performance is affected by fuel quality and vehicle filter design. In terms of fuel quality the key parameters to control, as the wax forms in the fuel tank, are wax crystal size, shape and content.

In the example below, the fuel has small sized, needle-shaped crystals, which means a porous wax cake would form on the filter. This maximises the tolerance of the filter to wax under different operating conditions, and makes it easier for the wax to re-melt.

For truck A, which is the new short-term (NST) emissions light-duty truck, we can say the borderline area of the drivability performance is around 1.5 wt% although some failures were observed below this level. Truck B tolerates a higher wax content since it is fitted with a recirculation system from the engine to fuel filter, which helps to re-melt the wax. Trucks C and D have smaller fuel filter volumes, but they have an electric heater to warm up the fuel, which has a huge impact on drivability. This trend was also observed in passenger cars. The results of testing two different types of passenger cars from Japan and Korea clearly show that the presence of an electric heater can contribute to drivability.

The results demonstrate that both fuel quality and vehicle fuel system design must be considered when assessing drivability performance.

In terms of fuel quality, it is important to consider the level of wax content at the target temperature and to select additives to ensure that smaller, easier to re-melt wax crystals are formed. The design of the fuel filters is a key consideration when trying to improve drivability performance. In our experience with both light-duty vehicles and passenger cars, those with very small filtration areas can have drivability limits close to the cloud point. Electric heaters and recirculation systems can be fitted to re-melt the wax, which can help to ease this issue.

Whether the fuel main filter is within the engine space or not also impacts the results. If the filter is located inside the engine space, where the temperature is relatively higher than outside, the wax accumulated on the filter is more easily re-melted. The use of extra filters, such as those in the in-tank pump of some passenger cars, is also a good option to consider when designing the system.

To maintain excellent cold operability performance in trucks and cars, both startability and drivability need to be considered. Since these parameters are affected by fuel quality and vehicle system design, field trial testing is the best way to assess the impact of changing these variables.

Operability can vary in different vehicles with the same fuel, and in different fuels within the same vehicle. In other words, winter operability is neither solely a fuel issue nor a vehicle issue, which is why Infineum conducts this field trial every year to obtain a better understanding of operability with the latest fuels and vehicles. Through this activity, we can derive improved additive formulations and share the data with OEMs and oil companies to help them continuously improve vehicle systems and fuel properties.

The Japan winter field trials provide an excellent opportunity for oil, additive and OEM organisations to work together to better understand the performance of their latest products in real world conditions.

This technical collaboration yields a wealth of new data and insight into vehicle operability. It means Infineum is well placed to help OEMs avoid future field issues in cold conditions and to help oil companies ensure their diesel fuels meet cold temperature operability targets in the latest vehicles. We are continuing to extend this testing activity by covering a broader range of fuels and by including vehicles from different regions, such as Europe and Korea, and we believe this collaborative work will provide significant benefits to our industry.

Sign up to receive monthly updates via email