Driveline

Rising demand for DCT fluids

09 December 2025

20 May 2025

Latest testing confirms outstanding performance of ultra-low viscosity e-fluid technology

As the personal mobility sector works towards net zero carbon emissions, OEMs are electrifying more models in their portfolios and seeking efficiency improvements from every component. Infineum Driveline Technologists, Hitesh Thaker and Yanzhao Wang, explain how friction results obtained in bench tests may not correlate to real world driving efficiency. They also reveal the extensive testing programme Infineum uses to ensure driveline fluids deliver the high efficiency and wear protection OEMs require for their electrified vehicles.

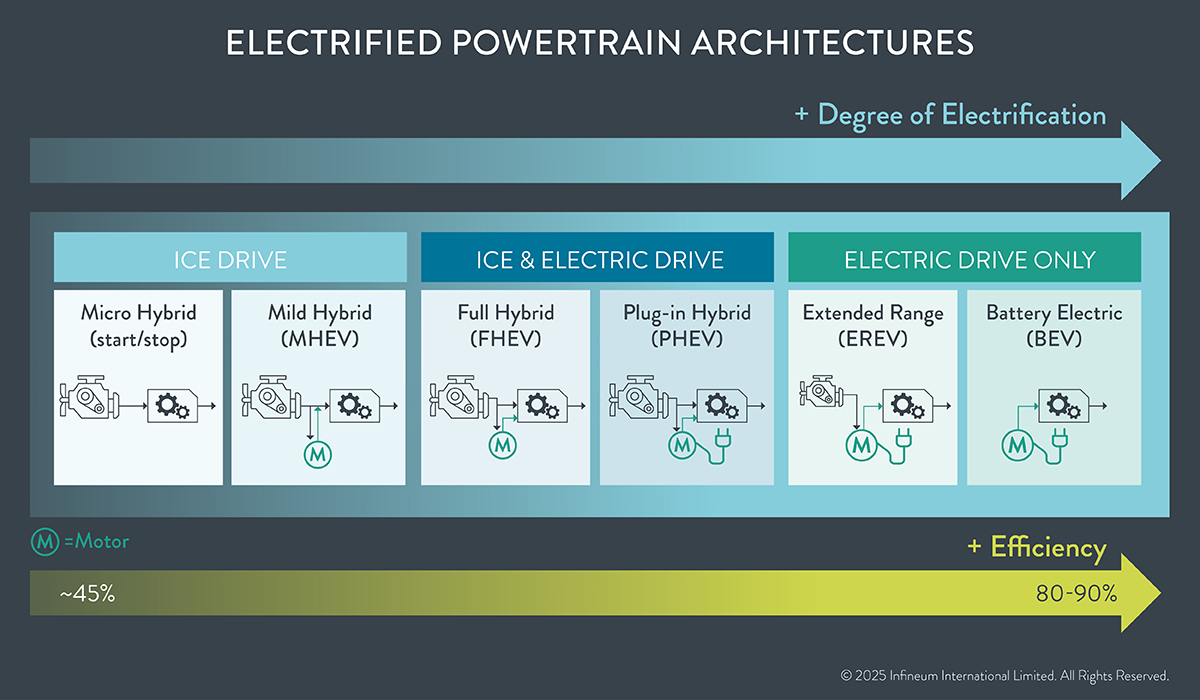

Electrification of the powertrain is expected to be the long-term greenhouse gas reduction strategy of OEMs operating in the passenger car market. While full battery electric models are already more than 60% efficient, OEMs continue to look for efficiency gains across their powertrain offerings.

One engineering trend, designed to further improve efficiency and power density in newer electrified vehicles, is the integration of the e-motor, gearbox and power electronics into one housing known as an electric drive unit (EDU). This has led to the need for dedicated e-fluids that can cool the electric motors while also protecting the gearbox.

These new e-fluids need to provide the performance and protection afforded by conventional fluids:

Aeration and Oxidation control – in smaller sumps and ‘fill for life’.

Frictional properties – when clutches are used.

Wear durability – for the gears, bearings and pump.

Efficiency – drag and churning vs. wear.

But, they must now go a step further. In these oil cooled e-motor systems, the latest e-fluids also need to focus on delivering electrical properties for insulation, preventing copper corrosion and ensuring sufficient motor cooling. To meet all the conventional and new requirements it is important to strike the right balance of base oil and additive technologies.

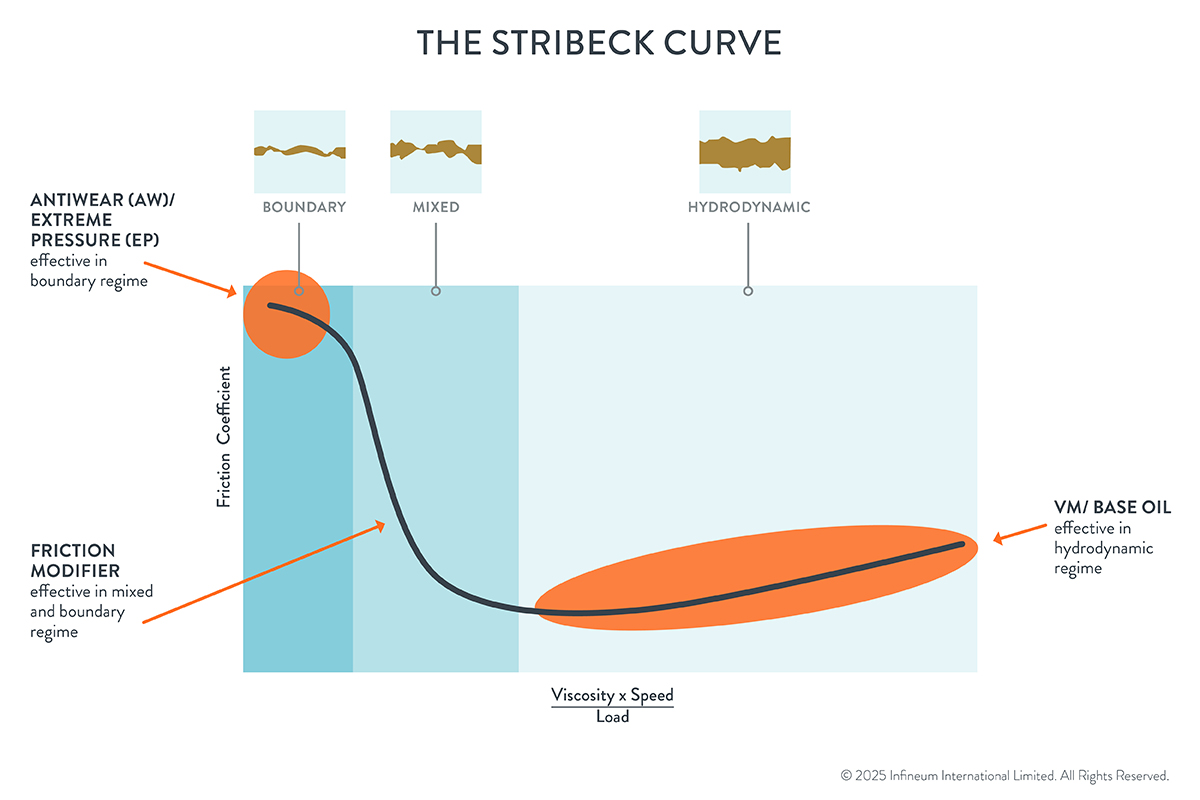

The Stribeck curve, measured by the mini traction machine (MTM), is a fundamental tribology tool, which is used to give an overview of the frictional performance of a lubricant. It can quickly assess the lubricant’s ability to reduce friction in the boundary, mixed and hydrodynamic lubrication regimes.

In the hydrodynamic region the surfaces are fully separated by the fluid film – with no contact between them. As speed decreases, fluid flow reduces, surfaces move closer together and the friction coefficient increases. Moving into the mixed regime, there is some contact between the two surfaces – although the oil film continues to help support the load between them. As the speed decreases further, we move into the boundary regime where there is hardly any oil film between the contact surfaces, and the load is supported by surface asperities. In both the mixed and boundary regimes, surface-active additives can have a significant impact.

A fundamental tribology tool that gives an overview of the frictional performance of a lubricant

Many OEMs and oil companies use the MTM to screen driveline e-fluids, where they may expect that fluids with lower friction should provide better efficiency credits in the vehicle EDU. In our experience, while this form of screener testing might provide some information about fluid performance, there is no clear correlation between friction properties in the boundary regime and mixed regime and EDU efficiency testing results. However, we do see some correlation between the two tests in the hydrodynamic region.

This disparity led us to design a test using an EDU to more accurately assess the impact of additives on energy efficiency. What we found was surprising.

Infineum has used the new EDU rig to carry out extensive efficiency testing to assess the impact of different additive and base oil combinations on energy efficiency. The efficiency was measured under Worldwide Harmonized Light Vehicles Test Cycle (WLTC) and steady state conditions, and candidate fluids were benchmarked against an API Group III based commercially available automatic transmission fluid.

First we assessed the impact of different base oils. All the test oils were formulated to a kinematic viscosity at 100°C of 3.0 cSt. The EDU efficiency testing results showed that Group IV base oil provided the most energy efficiency improvement, followed by combination of Group III with ester and then finally Group III. This finding is in line with industry observations.

But, when it comes to assessing the impact of additive technology another picture emerges. We tested fluids with the same Group IV base oil and kinematic viscosity at 100°C, but with different additive compositions. Here, we found that even though testing oils A and D show higher friction coefficient as measured in the MTM, they provide comparable or higher energy efficiency improvement (EEI) compared to lower friction oils B and C in both WLTC and steady state conditions. As you can see in the results below, there was not a strong correlation between the EDU energy results and the friction coefficient in the mixed regime of the Stribeck curve, and high friction fluids can deliver high energy efficiency improvement.

Our EDU energy efficiency map results indicate that test oil D, despite having the highest friction, delivered energy efficiency improvement in all operating regimes.

To further validate the results, we went on to carry out additional efficiency testing in a different EDU on oils A and D, plus two new candidate oils E and F with different additive packages. Each was formulated in the same Group IV base oil and kinematic viscosity at 100°C, two candidates with high and two with low friction coefficients in the boundary friction regime of the Stribeck curve.

In this round of testing, the efficiency was measured under the China Light-Duty Vehicle Test Cycle (CLTC) at three different temperatures: 20°C, 40°C and 60°C. As shown above, similar to findings in previous testing, higher friction candidate oils A and D delivered comparable or higher energy efficiency improvement than lower friction oils E and F.

Here we found that Infineum e-fluid technology, test oil D:

Provided close to 90% EDU efficiency.

Improved EDU efficiency by 1.75% at 20°C, which would enable BEVs to drive further in cold/cool temperatures.

Once again, our EDU efficiency testing has demonstrated that higher friction fluids can still deliver high energy efficiency improvement. No strong correlation was observed between EDU energy efficiency and boundary regime friction coefficient measured in the MTM Stribeck curve. This highlights the importance of fully evaluating candidate formulations rather than solely relying on MTM test data.

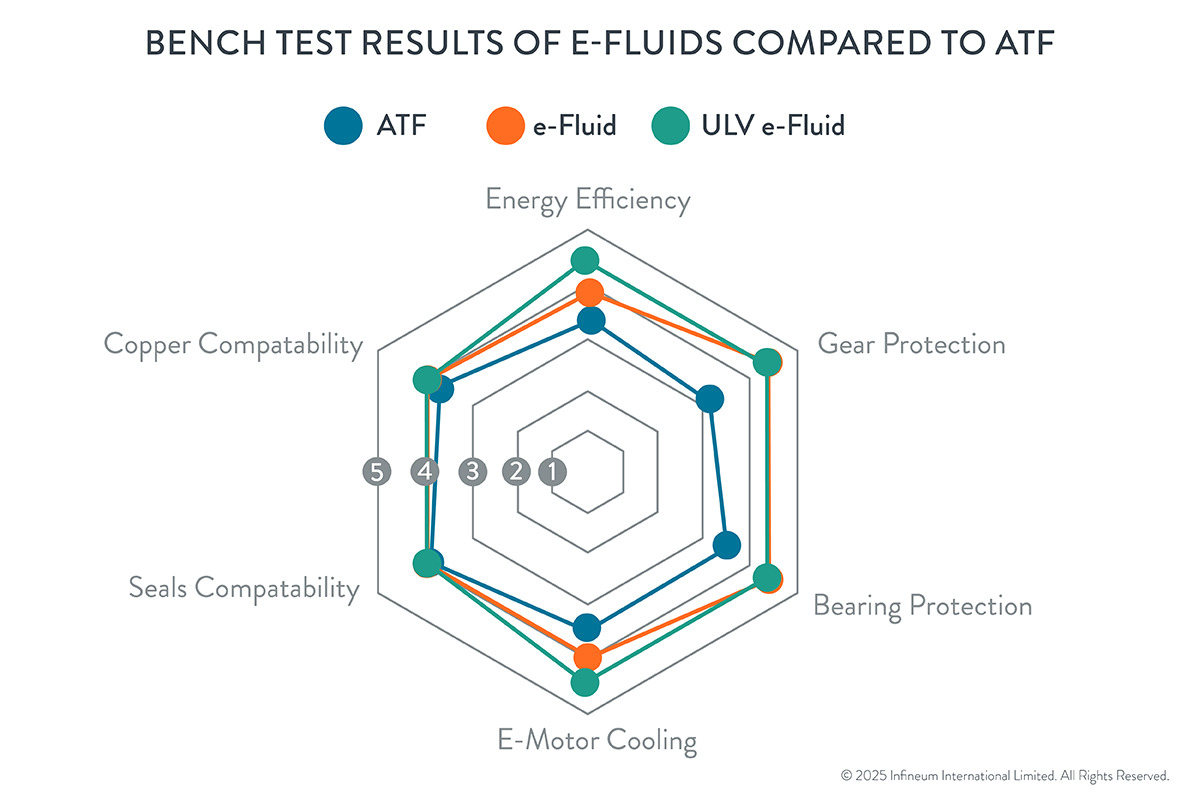

Improving efficiency is however only one side of the equation, we must also ensure fluids deliver excellent wear durability and materials compatibility. The strongest performing oil from efficiency testing, Infineum ultra-low viscosity e-fluid (3.0 cSt test oil D), was comprehensively tested in a number of bench tests where it demonstrated excellent wear protection and materials compatibility.

Note: ATF: 6 and 5.4 cSt, e-fluid: 4.5 cSt, ULV e-fluid: 3.0 cSt

We have completed over 1,000 hours of durability testing in an OEM electric drive unit rig – that’s equivalent to more than 200,000 km. Our ultra-low viscosity test e-fluid has delivered excellent results in all test parameters.

The end of test (EOT) parts look almost brand new, with no impact to gears, bearings and copper windings

In our view, it is important to test driveline formulations for electrified vehicles in conditions that mimic real world conditions. While bench tests such as MTM have a strong place in helping to quickly understand oil properties, it is important that the efficiency performance of candidates is more fully explored instead of relying on bench testing data alone.

Our research in this area shows that fluids returning high friction results in MTM, can demonstrate excellent energy efficiency improvement in EDU testing.

Infineum ultra-low viscosity e-fluids have achieved an industry leading up to 1.75% energy efficiency improvement. In addition, these fluids can also deliver excellent wear durability, seals and copper compatibility, aeration and oxidation performance that OEMs require.

We have been delivering outstanding protection to every type of transmission system for more than 25 years. Now, we are ready to step into the future, with formulations that meet and exceed OEMs’ expectations of durability and efficiency for electrified vehicles.

Sign up to receive monthly updates via email