Marine engines

OEMs outline challenges ahead

08 December 2025

17 February 2026

Marine fuel additives successfully used to resolve unexpected sludge problems in vessels at sea

It is a challenging time for global marine fuel users, with numerous quality issues reported in 2025, including high cat fine levels, flash point issues and fuel contamination. The operational issues that can arise, including those from increased sludging, can have severe implications for ship owners, ship operation and crew workload. Dewi Ballard, Infineum Global Product Manager for Marine Fuel Additives, discusses the challenges that variable fuel quality can bring and reveals how marine fuel additives have been used successfully to resolve sludge-related issues in ships at sea.

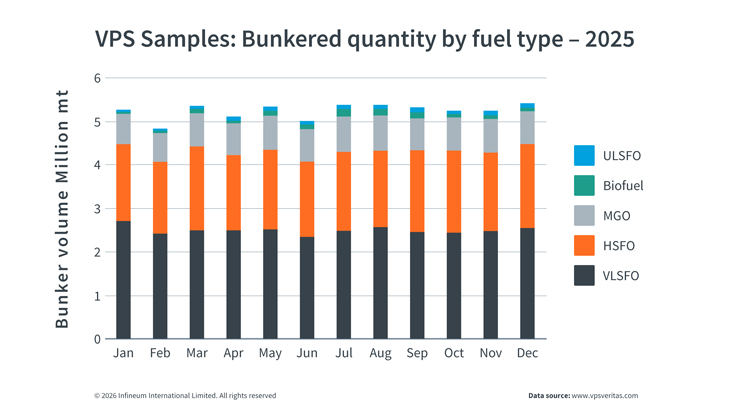

The latest data from Maritime Services Company, VPS, who tested 63 million MT of fuels delivered to ships in 2025, shows that very low sulphur fuel oil (VLSFO) was the year’s most popular marine fuel. Combined, VLSFO, high sulphur fuel oil (HSFO) and marine gas oil (MGO) accounted for 96.4% of fuel used, with biofuels and ultra-low sulphur fuel oil (ULSFO) making up only a small portion.

The organisation says in 2025 the number of bunker alerts, which indicate systematic problems where a number of off-specification readings are obtained, increased by 37% over the previous year, with VLSFOs being the fuel type requiring the highest number of alerts. The bunker alerts covered nine different test parameters, Cat-fines, Flash Point, TSP, Density, Seawater, Sulphur, Sodium, Potassium and ULO.

In terms of quality, VPS reports that VLSFO had an off-specification rate of 5.2% in 2025.

To produce 0.5% sulphur VLSFO, incompatible aromatic, high sulphur fuel components are blended with paraffinic, low sulphur components, which means asphaltene deposition (or sludge) is a common concern when using these fuels. While ISO 8217 includes the Total Sedimentation Potential (TSP) test to protect vessel operators, the test has limitations when it comes to ensuring trouble-free operation over extended periods. In addition, VPS states that while sulphur is the most common off-specification parameter, a high TSP accounted for 3.4% of off-specification VLSFO bunkers in 2025.

Click here to read our previous article on the causes of sludging and how ship and shoreside personnel can manage the risk and minimise the consequences.

Following a period of relative calm, our marine fuels team at Infineum is also seeing a change in fuel quality. Recently there has been an alarming rise in the number of reported fuel-related issues, especially with regards to sediment, compatibility and fuel stability – all of which can result in sludging. We asked some of our customers for their opinions on the difference marine fuel additives have made to their operations.

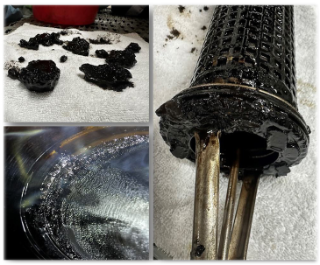

Sludge blocked the filters and purifiers, which

Sludge blocked the filters and purifiers, which A large cruise ship experienced an emergency situation, with severe sludging that clogged the purifiers and filters. After a few days the fuel was unable to reach the engine and de-bunkering was planned. Instead, the ship used Infineum fuel additives as an emergency treatment.

Afterwards, the Chief Engineer gave us an insight into how the use of fuel additives helped to resolve the situation.

“To my astonishment, the fuel additives not only cleared the sludge but also reconditioned the fuel to a degree I hadn’t seen before. We were able to burn the fuel for two days after the treatment. Fuel analysis confirmed 78% of sludge reduction and it has been possible to avoid the de-bunkering we had planned at the cost of 2,000 USD/Ton.”

Cruise Ship Chief Engineer

On switching fuels, a medium-sized Ultramax bulk carrier experienced issues with its fuel oil purifiers. The crew found sludge accumulating in the bowl housing, which blocked the purifier sludge discharge outlet pipe with hard accumulated sludge.

Following the use of Infineum fuel additives as an emergency treatment, the Fleet Manager gave us his thoughts.

“We added a fuel additive and carried out tank-to-tank recirculation of the fuel oil tank for 15 hours, maintaining a minimum feed rate of 700 litres per hour to both fuel oil purifiers, reducing the time interval of sludging operation. We found the observed sludge accumulated in the bowl housing was reduced and lessened while the purifiers sludge discharge outlets were free!”

Ultramax Tanker Fleet Manager

In a Supermax tanker the crew had been soaking dirty separation pads that had been affected by sludge in a special chemical detergent for a period of time and using steel wool to clean them, which was both a time- and labour-intensive process.

After a nine-month field trial of Infineum fuel additives, the tanker owner shared his views on the outcomes.

“The separation pads are generally clean and less adhesive overall and can now be cleaned using light oil and a wiper. Therefore, using fuel additive reduces labour and chemical consumption. The fuel additive has a very obvious effect of cleaning and dispersed cleaning of fuel sludge, it reduces wear and tear of fuel system parts and workload of crew members.” Supramax Tanker Owner

After using fuel additives, the filter was relatively easy to clean and needed cleaning less often

After using fuel additives, the filter was relatively easy to clean and needed cleaning less often

Ship owners and operators have two distinct choices when using fuel additives to manage sludging. The first is to use a maintenance dose regularly as a preventative measure, which can also reduce wear and tear on hardware and the crew’s maintenance and cleaning workload. The second is to store them on board for use in an emergency if sludge builds up.

The decision needs to carefully balance the cost vs the risk. A maintenance dose of additives to overcome the risk of using a poor quality fuel on a preventative basis means a reduced risk of sludge. This keeps the purifiers in better condition and less frequent cleaning of storage and settling tanks is required. However, for vessels confident in the consistently high quality of their fuel, stocking an additive on board would allow emergency additive treatment to be started straight away, should a poor quality batch of fuel be taken on.

The maritime industry is working hard to meet International Maritime Organization (IMO) decarbonisation objectives:

For the uptake of zero or net zero technologies/fuels/energy sources to represent 5% striving for 10% of the energy used by international shipping by 2030.

Reach net zero greenhouse gas emissions close to 2050.

This means another shift in the type of fuels used could be expected and new challenges may emerge across the whole spectrum of marine fuels.

Infineum will be ready with cost-effective fuel additives that match the changing needs of the maritime industry. These advanced solutions will help vessel operators reduce maintenance costs and downtime, improve efficiency and reduce emissions output, to meet the IMO goals.

Sign up to receive monthly updates via email