Driveline

Energy efficient e-fluids

28 May 2024

13 August 2019

Severe field testing confirms outstanding anti-shudder performance and gear protection

A recent Infineum field trial, designed to meet some of the most severe requirements for automatic transmissions, has finished after clocking up 100,000 kilometers. Watch the outcome on video and read on to learn more about the outstanding performance achieved in extreme real world driving conditions.

Infineum International Limited

As performance requirements for the transmission market continue to increase, Infineum continually evolves to find the right fluid solutions.

Field testing provides a true test of the quality of our technology. Many O.E.Ms mandate the generation of field test data in order to obtain their specific approvals. Our impressive track record in managing and delivering field trials, helps deliver performance you can rely on.

Our latest field trial was designed to meet the most severe requirements for Z.F. 8 H.P. automatic transmissions.

Conducting our field trials in extreme real-world conditions is key to developing field proven products, pushing our technology to its limits. And this trial was no exception; in fact, this was the most demanding trial we’ve ever created.

We took three of the latest production BMW 5 Series passenger cars and loaded them to their maximum allowable weight. On top of the heavy load, the route mapped out in Germany provided diverse driving conditions to accumulate 100,000 kilometers. Route included city roads, cross-country routes and motorways, enabling us to push the vehicles up to the speed of 190 kilometers per hour.

As if that wasn’t demanding enough, for 50 percent of the trial we also attached a fully loaded air drag trailer to each vehicle, adding another 2,000 kilograms, resulting in an overall vehicle weight of over 4.5 tons! At this weight, we dropped the maximum speed to 100 kilometres to ensure we were within the legal limit.

With the expertise of professional engineers and drivers, we tested the vehicles drivability at the start, middle and end of the test. The transmission demonstrated excellent shift behaviour at each stage of the trial, indicating the remarkable anti-shudder durability performance of the fluid in these truly demanding conditions.

When we inspected the transmission hardware at the end trial, we were delighted with the results.

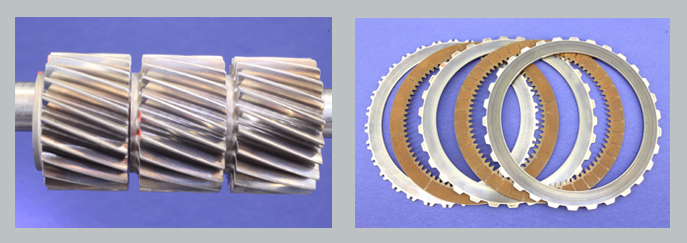

The inspection of all of the parts gave an outstanding result. The parts are almost like brand new and they are very good for going a lot, lot, longer.

If I look at the gears, usually you will find micro pitting, you will find pitting or wear in the gears. But actually, if you look at these parts they look almost like new. We really in-depth checked for micro pitting, we checked for wear, we checked for real pitting and we couldn’t find anything. The parts are absolutely in perfect condition.

Finding zero issues with key components like the gears, friction plates and bearings was truly outstanding after such severe testing. Not only did the inspection confirm the reliability of our fluid throughout the 100,000 kilometres test, it also demonstrated the superior performance our technology can provide in real-world driving conditions.

As transmission makers work to minimise fuel consumption while improving acceleration and driving comfort they are making significant changes to their hardware. Lighter weight systems, an increased number of speeds and new gear set designs with fewer shift elements are just some of the changes designed to improve driveability and fuel economy. In these latest automatic transmission designs, the fluids must be engineered to improve gear and bearing efficiency while also delivering wear protection over longer drain intervals - even when the components are heavily loaded.

Today’s transmission fluids not only help to improve efficiency and drivability but also ensure exceptional hardware protection.

To assess the performance of its new automatic transmission fluid (ATF) formulation, Infineum designed a severe field trial to meet the challenging requirements for ZF systems. The testing took place in three of the latest production BMW 5 Series passenger cars, fitted with ZF eight-speed automatic transmission systems. Two of the vehicles were used to test the Infineum candidate ATF, while the other was filled with a ZF factory fill fluid to act as a reference.

Field trials in extreme real world conditions push our technology to its limits and this was the most demanding trial Infineum has ever created.

After an initial 3,000 km run in period, the vehicles were loaded to their maximum allowable weight (500 kg) and run over diverse driving conditions for 100,000 km. The test route included a small proportion of city roads and cross-country routes while almost 75% was on motorways, primarily selected to enable the vehicles to be pushed up to speeds of 190 kilometers per hour (km/h).

To increase the severity of the trial, for 50% of the time the vehicles were hitched to fully loaded hard-top trailers, increasing air drag and adding another 2,000 kilograms. This pushed the overall vehicle weight up to more than 4.5 tons, which meant the maximum speed was reduced to 100 km/h to adhere to legal limits.

The transmission fluids were not changed throughout the entire 100,000 km field trial, although regular oil samples were taken for analysis.

Fully loaded hard-top trailers increased air drag and pushed the overall vehicle weight up to more than 4.5 tons

Fully loaded hard-top trailers increased air drag and pushed the overall vehicle weight up to more than 4.5 tons

Professional engineers and drivers carried out drivability assessments. The first was conducted after the run in period, the second at 50,000 km and the last at the end of the test. Here the shifts during a variety of driving operations, for example, acceleration, deceleration and kick down, (where the driver shifts down to accelerate quickly) were rated. While all of the vehicles showed fluid performance degradation at the end of the test, no issues were raised by the drivers. However, some harshness of shifts during kick down was noted and an increase in the level of shudder when shifting from reverse to first gear was felt. In these tests, the Infineum candidate ATF provided better drivability performance than the factory fill reference fluid.

The transmission demonstrated excellent shift behaviour indicating the remarkable anti-shudder durability performance of the new fluid under these tough conditions.

To asses wear performance, elemental analysis of the ATF was carried out during the trial. No concerning levels of wear element ingress for either the candidate or the reference oils were observed..

The inspection gave an outstanding result – all of the parts were in near perfect condition.

After 100,000 km in these very severe conditions it would be normal to find micro pitting or pitting or wear in the gears. But, on inspecting the transmission hardware at the end of the trial, almost no sign of these issues was found. In addition, no issues at all were reported with any of the key components, including the gears, friction plates and bearings.

The inspection gave outstanding results

The inspection gave outstanding results

The results from this extreme testing programme have confirmed the reliability of the new automatic transmission fluid and demonstrated the superior performance Infineum technology can provide in severe real world driving conditions.

Sign up to receive monthly updates via email