Passenger cars

ASEAN a market in transition

09 December 2025

Please note this article was published in June 2012 and the facts and opinions expressed may no longer be valid.

01 June 2012

Salicylates for top tier crankcase and marine formulations

Robin Scott, Automotive Development Manager, and Eddie Wilkinson, Marine & Large Engines Technology Manager, look at the progress of Infineum’s project to build new salicylate production facilities in Singapore and at the advantages this technology delivers to crankcase and marine lubricant formulators.

Salicylates are valuable, differentiated components with advantages in top tier lubricant formulations. They are used to deliver detergency in passenger car, heavy-duty, marine, gas engine and railroad engine lubricant formulations.

Salicylate formulations differ from the majority of formulations using phenate and sulphonate in that only a single surfactant type is needed.

The salicylate soap provides both the required engine cleanliness and supports sufficient dispersed base to neutralise acid in the engine. However, due to its potency, a high level of formulation expertise is required to use salicylate technology effectively. In addition, not all salicylate technologies are the same.

Infineum produces a wide range of calcium and magnesium salicylate grades because differences in composition result in subtle variations in performance that must be addressed and optimised in the final formulation.

The progress that has been made to reduce vehicle emissions over the years is impressive. Emissions of NOx, hydrocarbons and particulate matter have all been dramatically reduced by aftertreatment innovations such as the three way catalyst and diesel particulate filter.

Today’s top tier lubricants must deliver engine durability and sustained fuel economy without compromising emissions system performance.

Achieving this balance has become increasingly challenging. And as chemical constraints are introduced and tightened in lubricant specifications across the globe, complex chemistry and sophisticated lubricant formulations are required.

The development of top tier formulations that offer the desired performance benefits but with lower levels of sulphated ash, phosphorus and sulphur (SAPS) has been an area of considerable focus for the additives industry.

For example, Infineum has based its salicylate chemistry on a sulphur-free molecule and the resulting components deliver several advantages:

Another advantage of calcium salicylates over their sulphonate counterparts is that they can have a lower friction co-efficient which means, if formulated optimally with other components, they can deliver fuel economy benefits.

Medium speed, four-stroke trunk piston engines used to power coastal and cruise ships typically run on heavy fuel oil (HFO).

They are designed to have low oil consumption, to burn a wide range of fuels, and to offer safe, economical and reliable operation. The lubricant must be capable of neutralising combustion acids, dealing with water contamination, dispersing combustion products, handling the asphaltenes in the HFO (which can migrate to the lubricant), and controlling deposits on the piston undercrown and ring grooves.

Today, all trunk piston engine oils (TPEO) are formulated in Group I base stocks and, in combination with salicylate detergents, these offer excellent deposit control compared with lubricants formulated with a combination of sulphonate and phenate detergent technologies.

However, changing base stock production trends, driven by the crankcase market, mean the use of base stocks with higher saturates is increasing. In the future this will result in marine lubricants being increasingly formulated in Group II base stocks.

The relatively inferior solvency of Group II compared to Group I base stocks means the oil may be unable to handle the asphaltenes adequately, which could lead to the formation of black sludge and piston undercrown deposits.

Superior dispersion of asphaltenes is becoming increasingly important for future marine TPEO formulations.

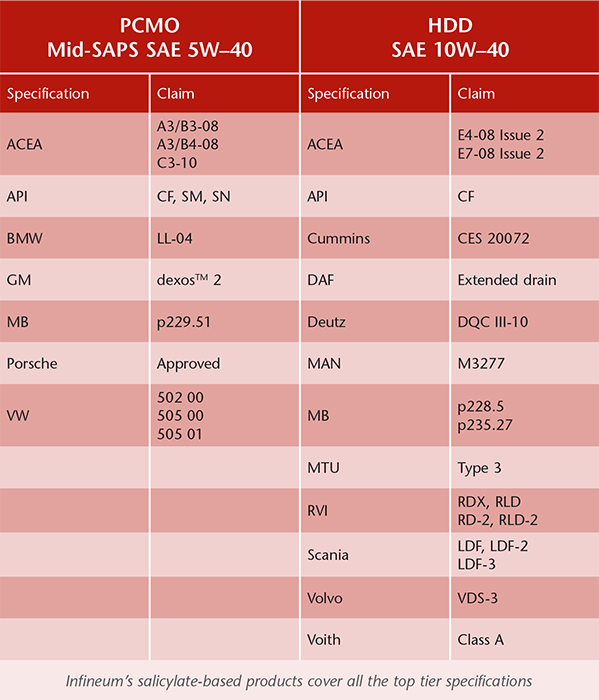

Infineum has developed several crankcase and marine lubricant products using salicylate technology, which have been extensively tested in the field and laboratory.

This development work has revealed that it is not only essential to select the right salicylate for the right application, but also to ensure that the correct balance of salicylate and metal overbasing alkali are employed to ensure that all the benefits of the technology can be utilised effectively.

In 2003, Infineum introduced its first passenger car mid-SAPS salicylate-based product that met all the required specifications across a wide range of generally available Group III base stocks.

Building on this experience, a low-SAPS product, which meets a unique combination of claims including the ACEA C4-10, MB p229.51 and Renault 0720 specifications has been developed.

In the heavy-duty diesel world Infineum salicylates can deliver long drain performance by providing excellent acid neutralisation and antioxidancy, which helps to keep the engine clean even when high sulphur or biodiesel containing fuels are used.

In addition, the technology offers fuel economy retention throughout the extended drain interval – something end users value as they seek to minimise off road time and reduce fleet running costs.

In TPEO formulations salicylates provide excellent asphaltene handling and water shedding properties (critical for marine engines using HFO), and improved cleanliness, antioxidancy and base number retention compared with sulphonate and phenate-based products.

Development and testing work in Group II base stocks has demonstrated that salicylates and a booster can deliver at least equivalent cleanliness performance to current Group I formulations. This means Infineum is ready for the use of Group II base stocks in marine TPEO formulations.

Infineum recognises that supply security is of vital importance in top tier lubricant formulations and is investing in the construction of a new world-scale salicylates unit in Singapore.

The flexibility to increase capacity has been built into the plant’s design, which will allow Infineum to meet the needs of this growing market. At the same time, the combination of this new plant and existing production facilities in France mean increased supply reliability can be offered to our customers around the world.

The project has successfully progressed through the Front End Engineering Design (FEED) and the selection of a contractor for the detailed Engineering, Procurement and Construction (EPC) processes is complete.

Field construction is now expected to begin in mid-2012, keeping the project on schedule to meet the 2013 start up target.

Sign up to receive monthly updates via email