Commercial vehicles

ACEA HD Sequences released

22 January 2025

25 February 2019

Delivering enhanced protection in all critical performance areas

Today’s heavy-duty vehicles are using a broad range of engineering technologies and fuel types to meet tightening emissions regulations, while also meeting end-user demands for lower running costs and less down time. Insight explores the changing market dynamics and the growing need for multifuel lubricant technology.

Energy efficiency and the use of alternative fuels are central to many commercial vehicle OEMs’ strategies for meeting the stringent emissions limits that are being set in air quality policies.

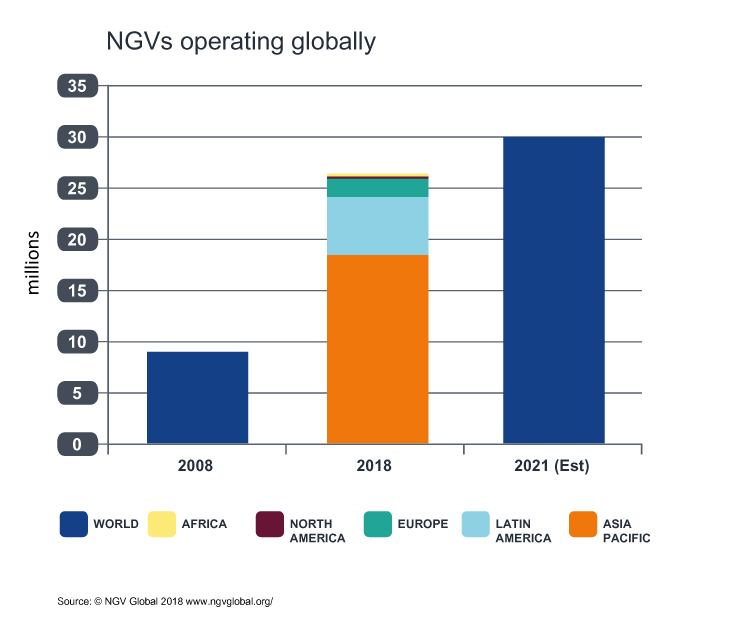

Natural gas is a low-carbon, cleaner-burning fuel that is economical and in abundant supply. The Natural Gas Vehicle Association reports that replacing a diesel burning heavy-duty truck with one running on natural gas is the emissions equivalent to removing 119 traditional combustion engine cars from the road. On the face of it this makes natural gas a good option for use as a transportation fuel. But, infrastructure is still limited, with only 31,000 filling stations globally (60% in Asia Pacific) and this, combined with slow refueling, limited vehicle range, higher purchase price and lengthy return on investment periods, means the uptake of vehicles powered by this fuel has been slow. Currently it is estimated that some 26 million of the more than a billion vehicles in use today are powered by natural gas – 95% of which are light-duty vehicles.

With more than 200,000 natural gas heavy-duty trucks and buses, China is the largest gas for transport market in the world . Looking ahead, we can expect these numbers to grow as China announces that by the end of 2020, it will replace more than one million out-dated heavy-duty diesel trucks with more modern electric or LNG trucks that are capable of complying with China VI emissions limits.

Engine technology is continuing to develop - rapidly closing the performance gap with diesel. The new generation of commercial vehicles now emerging are increasingly attractive to operators and offer a viable alternative to electrification.

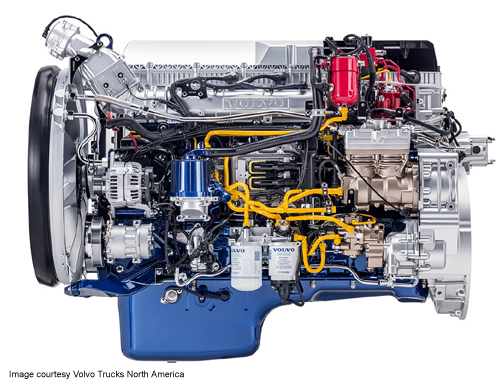

In Europe, Volvo Trucks, for example, says it is offering liquefied natural gas as an option to meet customer demands for lower CO2 emissions without compromising on performance or productivity. The OEM has outlined the technical solution behind the LNG driveline – saying it builds on proven diesel technology. When the truck runs the liquid natural gas is heated and turned to compressed gas and, before it is injected, a very small amount of diesel is added to the cylinder to initiate ignition. Volvo Trucks expects that one of the big challenges of working with these high–pressure gas vehicles will be to ensure the system is tightly sealed; which means all the seals must offer long-term durability.

Volvo Trucks’ gas-powered engine uses the Diesel principle instead of Otto

technology to achieve higher horsepower and torque.

Volvo Trucks says this set up gives all the advantages of diesel - including high horsepower and torque - but emits 20% less CO2. And, when the truck is fuelled with liquid biogas, which can be derived from organic waste such as green waste, animal residue and sewage, the OEM reports that tank-to-wheel CO2 emissions can be reduced by 100%.

In North America, Cummins has announced that its ISX12N 400 hp natural gas engine is certified to the California Air Resources Board’s optional low NOx standard of 0.02 g/bhp-hr, throughout a range of duty cycles. The OEM says that the engine has ‘electric-equivalent’ emissions when running on renewable natural gas.

The engine utilises proprietary spark-ignited, stoichiometric combustion with cooled exhaust gas recirculation technology, and maintenance-free three-way catalyst aftertreatment. No diesel particulate filter or selective catalytic reduction aftertreatment is required. The ISX12N has been in production since February 2018, and Cummins says that over 1,000 have been produced for its North American customers.

These latest natural gas engines demand higher performance from the lubricant. And, as oils trend to thinner SAE 10W-30 viscosity grades for improved fuel economy it is essential to ensure they can deliver robust wear protection over an extended oil drain interval.

To protect its natural gas engines using stoichiometric combustion over longer drain intervals, Cummins has introduced a new mobile natural gas engine oil performance specification - CES 20092. One of the key requirements is a two-year field test across multiple natural gas platforms, which demonstrates wear and corrosion protection, oxidation and nitration control, cleanliness performance and emulsion resistance. A second requirement of the new standard is to pass an engine dyno test designed to stress the oil’s oxidation and thermal stability in the natural gas environment.

With the use of CES 20092 approved oils, Cummins has recommended increasing the oil drain interval for its ISX12N gas engine to 40,000 miles/64,000 km for vehicles with average road speeds of greater than 25 mph/40km/h. Cummins says all its natural gas engines using stoichiometric combustion will benefit from a transition to CES 20092 oils, which require a more modern oil additive system than previously used for CES 20074 or CES 20085 oils. The new specification requires a much stronger antioxidant combination to provide protection at the high temperatures experienced in modern mobile natural gas engines.

As more fleets operate multiple engines on different fuel types, it is increasingly advantageous for engine oils to offer protection in a multifuel world. What is needed for these fleets is a single oil that is approved across the fuels – meeting the latest Cummins CES 20092 gas engine standard, offering protection for diesel engines above API CK-4 and OEM specifications and carrying API SN approval for gasoline engines.

A multifuel lubricant technology approach delivers considerable value to mixed fleet end users, who are looking to reduce total cost of ownership, cut lubricant inventory costs and remove misapplication concerns.

Diesel, gasoline and natural gas engines have very different requirements from the lubricant standpoint. By using innovative technology and advanced formulation know-how, it has been possible to meet, and exceed, the various needs of engines operating on all these fuel types in one package.

Sign up to receive monthly updates via email