Passenger cars

Severe hybrid engine oil testing

20 May 2025

04 August 2020

Use of motor oils that do not address real engine requirements is a false economy

To ensure oils offer the necessary protection to engines and aftertreatment systems OEM, lubricant and additive companies work together to develop appropriate industry lubricant specifications. However, across the world, there is evidence that some end users are opting for unlicensed oils. Mathieu Consigny, Infineum Principal Technologist, explains how the use of these unapproved engine oils could not only be damaging vehicle hardware but also the environment.

To meet tightening emissions and fuel economy targets vehicle OEMs have added new hardware systems, downsized components, introduced new materials and improved combustion. These are just some examples of the changes that have driven innovation in engine oil formulations, with the rate of research and development investment by additive companies now comparable to the pharmaceutical industry. However, the fact that the oil is a key component of the engine is not always fully understood by end users and there is a low awareness of just how incredibly sophisticated and complex engine oils have become.

Developing motor oils that are capable of delivering the performance needed to lubricate the latest engines requires a deep understanding of the hardware and a thorough understanding of additive components, their credits, debits and interactions. Vehicle manufacturers, lubricant and additive companies build such expertise from years of investment in the evaluation of new components and formulation approaches via extensive engine testing and rigorous field trials. Guessing, assuming and hoping have no part to play in this environment.

Industry lubricant specifications were developed to define the quality level of products that will provide good lubrication when used as recommended and deliver a level of performance on which marketers, OEMs and consumers can rely.

Industry specifications are updated regularly to ensure they continue to meet the needs of the latest engine hardware and to replace tests as hardware becomes unavailable.

In North America, the latest ILSAC GF-6/API SP specification was introduced for passenger cars in May 2020 and in the heavy-duty market API CK-4 and FA-4 have applied since 2016. In Europe, a revised version of the ACEA 2016 Sequences was launched in 2018 and a new release of both the light-duty and heavy-duty Sequences is under development. In Japan, JASO recently developed the GLV-1 specification to support Japanese OEMs that are transitioning to lower and lower viscosity grades. The development of these new and revised specifications requires significant investment of time and money from OEMs, oil and additive companies. However, they are essential as they form a very strong foundation on which OEMs can build additional specifications to address specific performance requirements.

Many of today’s engine oil specifications include constraints to limit the use of some chemicals in order to protect parts of the engine and to comply with legal obligations. For example, the ash generated when metals such as calcium, magnesium and sodium are burnt in the engine can plug and damage the vehicle aftertreatment system, jeopardising the environmental protection they are designed to deliver. In the same vein, phosphorus is known to poison the catalysts used to reduce unburned hydrocarbons.

Reducing the amount of sulphated ash, phosphorus and sulphur (SAPS) in engine oils has been a major research topic for additive suppliers over the past decade.

However, these elements also have strong features including acid neutralisation for calcium and magnesium, antiwear for phosphorus containing components and antioxidant capabilities of the sulphur containing components. This means it has been a significant challenge to reduce them in formulations. However, oils with reduced SAPS are now available on the market, which offer better engine protection than in the past and, at the same time, take care of the environment.

While a chemical signature can tell us something about a motor oil, it is by no means a guarantee of performance.

For example, some chemical compounds, such as silicon used in antifoam additives, bring very useful features to the oil. But, a chemical signature of silicon will tell us nothing about the additive used and the credit (or damage) that can be expected from it - after all, adding sand (SiO2) would be of no help!

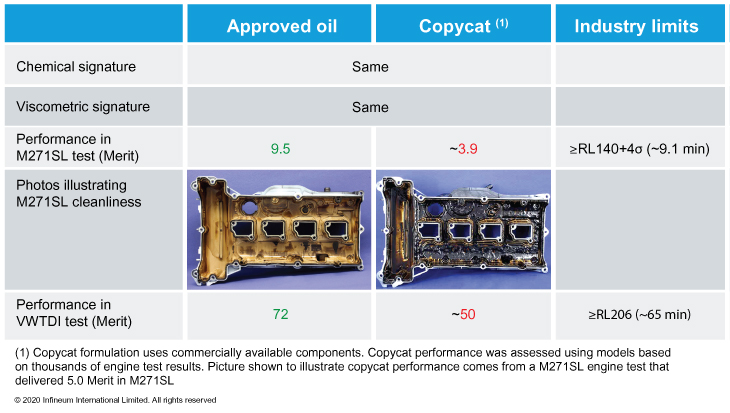

In evaluations carried out by Infineum, typically available components were used to formulate two oils with the same chemical signature, which gave very different results, particularly with respect to cleanliness and sludge.

It is clear that while chemical signatures give some indication of oil composition, they provide no information about performance or compatibility.

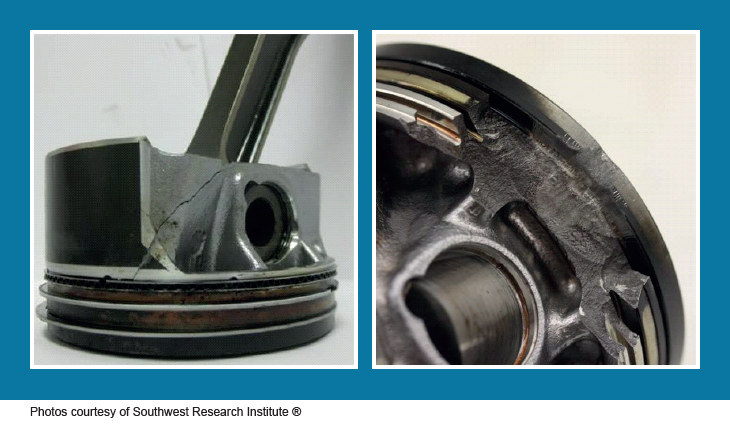

Innovations introduced by vehicle manufacturers often create new performance requirements for motor oils, sometimes vital to the engine. As an example, downsized car engines have been developed to cut fuel consumption and hence reduce CO2 emissions. These engines are often turbocharged, smaller displacement designs for the same or higher amount of power than the engines they replace. With high compression ratios and optimised fuelling, sections of the engine’s speed load /map could lead to a phenomenon called low-speed pre-ignition (LSPI), which can result in dramatic engine damage. New lubricant features were required to help prevent LSPI, and LSPI tests are being incorporated into the latest engine oil specifications.

Two examples of piston damage due to LSPI observed during testing at Southwest Research Institute ®

Another recent evolution is the use of low viscosity oils, such as SAE 0W-16 in passenger cars and SAE 5W-30 in heavy-duty vehicles. The aim here is to minimize friction losses in the engine and hence reduce fuel consumption. At the same time we are also seeing the use of new materials and coatings that sometimes have dramatic incompatibilities with certain additive components.

These continuous innovations mean that using oils that have been approved by the vehicle manufacturer is increasingly crucial, and is a requirement to benefit from the manufacturers warranties. This focus on oil conformity is also becoming more apparent in the field, with verification campaigns and industry publications by various industry bodies, including ATC, ATIEL, UEIL and VLS, highlighting these concerns. These activities, together with the development of in-use emissions tests for vehicles, reinforce that the importance of compliance is higher than ever in the motor oil marketplace.

The owner manual lists the viscosity grade and performance level required for each specific vehicle. Oils carrying industry quality marks, such as the API ‘Starburst’, or displaying the ACEA or JASO quality level have been rigorously tested to ensure they meet the required standards.

Using an oil that has been approved for the specifications requested by the vehicle manufacturer provides the best assurance to owners that their vehicles are well protected, and can operate in optimal conditions.

Oils without demonstrated credentials and their underlying comprehensive engine testing programs can have serious drawbacks for the end user in terms of possible engine damage, increased fuel consumption and higher fuel bills. In addition, the use of these unproven or unsuitable oils can lead to increased emissions arising from sub-optimal aftertreatment system performance, which may have a detrimental impact on human health and the environment.

Sign up to receive monthly updates via email