Passenger cars

Severe hybrid engine oil testing

20 May 2025

17 February 2016

Research uncovers road to increased lubricant derived fuel economy

Intense industry-wide interest in the improvement of fuel economy has driven significant change to vehicles and lubricants. With this in mind, Infineum has been looking for ways to better understand fuel economy measurement in order to design lubricants that deliver maximum fuel economy improvement.

Tightening CO2 emissions legislation means the global automotive industry is being challenged to find ways to further improve vehicle efficiency to avoid the significant fines for non-compliance. While OEMs are responding with innovative hardware designs for their latest vehicles, the lubricant and additive industries are working to reduce frictional losses in the engine to help improve the fuel economy of both new and existing vehicles.

By replacing sliding components with rolling ones, improving component manufacturing to achieve tighter clearances and by using new surface materials, OEMs have reduced friction in the engine. In addition, during normal operating conditions, the balance of boundary and hydrodynamic lubrication has shifted towards the hydrodynamic regime. This has enabled the introduction of lower viscosity lubricants.

Lower viscosity lubricants further reduce frictional losses in the hydrodynamic regime, with viscosity grades below SAE 20 now in use.

While the push for even lower viscosity oils continues, two questions arise. First, will further reductions in viscosity result in ever improving fuel economy? And, second, what are the best ways to measure fuel economy that relate to real life operating conditions and consumer experience? Infineum has been investigating the impact of drive cycle, vehicle type and VM chemistry to help find answers to these questions.

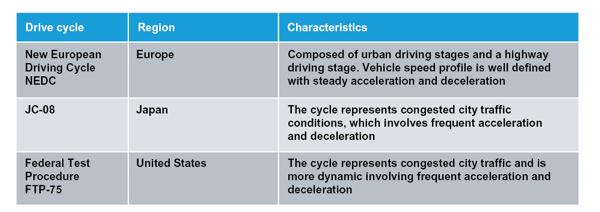

Currently, three driving cycles are used to evaluate vehicle efficiency – each with different cycles characteristics and speed profiles to represent regional conditions.

Not surprisingly, research undertaken using different driving cycles has yielded wide-ranging results on potential performance gains. At the same time, the type of vehicle used in fuel economy evaluation in the same cycle plays a significant role.

In recent studies Infineum has used the chassis dynamometer test in all three driving cycles in the same vehicle and used one cycle to compare lubricants in different vehicles. In addition, the impact on fuel economy performance of viscosity and additive chemistry of the lubricant has also been assessed. This work is designed to better understand the factors that influence fuel economy performance and to deliver maximum lubricant-derived fuel economy improvement (FEI).

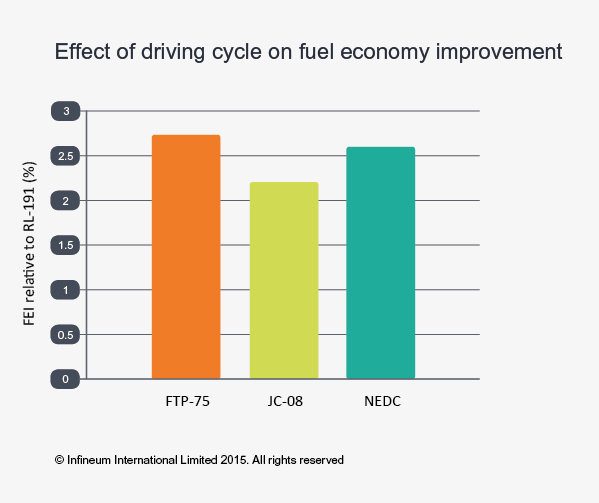

The variation in fuel economy results between various drive cycles and vehicles means that a baseline relative to a recognised reference oil must be established. Infineum used the industry reference oil RL 191 (SAE 15W-40) to establish baseline fuel economy performance in the same vehicle in each of the three driving cycles. The FEI of different test oils can then be compared against these results.

A candidate SAE 0W-20 was evaluated, and although FEI of 2-3% relative to the reference oil was demonstrated across all the driving cycles, the degree of improvement was different for each. The highest FEI for the candidate oil was observed in FTP-75 drive cycles followed by NEDC and JC-08.

Fuel economy improvement of an SAE 0W-20 candidate oil relative to industry oil RL 191 measured in the same vehicle

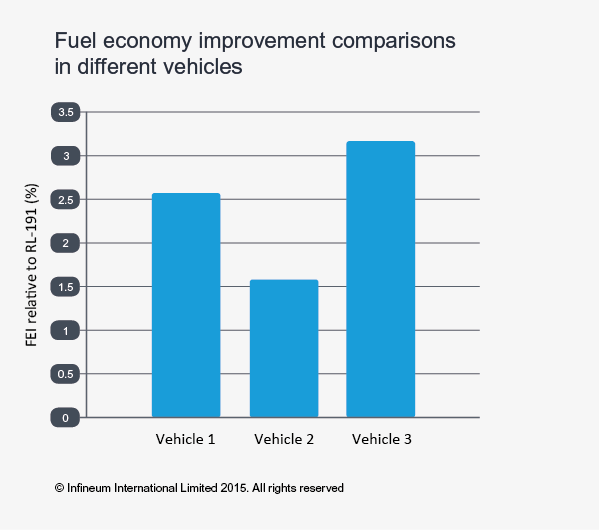

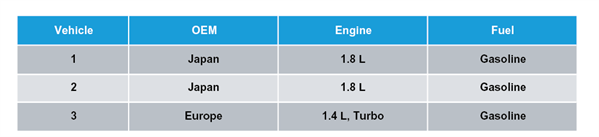

Another factor that can significantly impact fuel economy performance is the engine itself. In order to study the effect of engine type, a candidate oil was evaluated in three different vehicles using the NEDC driving cycle. The FEI of the oil, relative to RL 191, across the three vehicles ranged from 1.6% to 3.2%. Surprisingly, even for vehicles with the same engine size the FEI was seen to vary by 1%.

Fuel economy improvement of the candidate oil relative to RL-191 run in different vehicles under NEDC

Fuel economy improvement is closely related to two engine oil parameters: friction modifiers and engine oil viscosity. The effect of the former is well understood. But, because lowering oil viscosity can potentially cause engine hardware wear and durability issues, there is value in finding other ways to gain FEI.

An alternative strategy is to optimise the lubricant viscosity profile using viscosity modifiers so that, at a fixed high temperature high shear viscosity at 150oC, the viscosity at lower temperatures is minimised. This means that not only are frictional losses minimised at typical operating temperatures, but also engine protection is provided at peak temperatures.

Infineum evaluated the fuel economy performance of three VM types – conventional hydrogenated styrene diene (HSD), fuel economy hydrogenated styrene diene (FE-HSD) and a fuel economy polymethacrylate (PMA) in SAE 0W-20 oils. In testing, using all three driving cycles, the FE VMs delivered an additional 0.5-1% FEI credit compared to oils formulated with conventional HSD.

This work has demonstrated that oils formulated with FE VMs can deliver improved fuel efficiency without compromising engine protection.

By understanding the influence of viscosity, additive chemistry, driving cycle and vehicle type on fuel economy performance, Infineum is pinpointing the best ways to get maximum fuel economy improvement from the lubricant.

Reprinted from SAE Japan / SAE International Paper 2015-01-2042 Copyright © 2015 SAE Japan and SAE International. A complete copy of the paper may be obtained from SAE at www.sae.org. Original source: Cui, J., Oberoi, S., Briggs, S., Goldmints, I., and Baxter, D., 2015, "Measuring Fuel Efficiency in Various Driving Cycles: How to Get Maximum Fuel Economy Improvement from the Lubricant," SAE Technical Paper JSAE 20159039 / SAE 2015-01-2042.

Sign up to receive monthly updates via email