Marine engines

Fuel additive sea trials

08 July 2025

23 January 2024

How fuel and lubricant additives can help shippers reduce emissions and improve efficiency

The marine industry has been through a period of unprecedented change, with tightening emissions regulations and the impact of the global pandemic creating new challenges. Insight explores how fuel and lubricant additives have supported the introduction of new fuels and helped improve efficiency while keeping ships reliably in service for longer and explores how additives help towards the industry’s net zero ambitions.

The last eight years have been extremely challenging for the marine industry. First, the International Maritime Organization (IMO) began a journey to reduce emissions by cutting sulphur levels in marine fuels. The 2020 implementation date coincided with the global pandemic, which brought the world to a standstill. Now, as the industry continues to recover, we are entering a new period of change as efforts to decarbonise the international shipping fleet intensify.

As the IMO 2020 sulphur reduction deadline approached, we witnessed significant industry uncertainty on whether to continue using high sulphur fuels with an exhaust gas scrubber or to switch over to very low sulphur fuel oil (VLSFO). As the price spread between high and low sulphur fuels narrowed, the majority opted for the latter option.

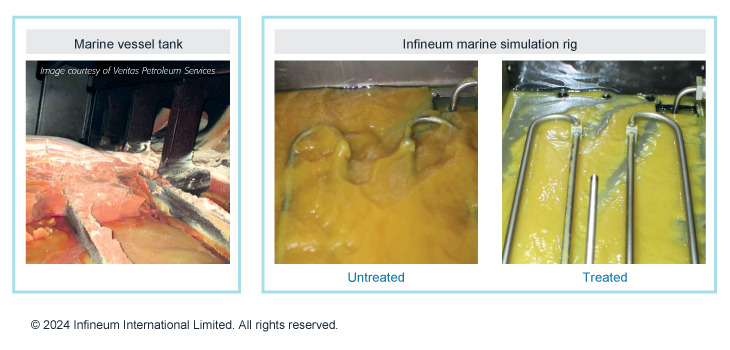

Anticipating this outcome, we identified the critical performance challenges associated with the use of VLSFOs: asphaltene stability, lubricity and wax management, and were ready with cost effective marine products in these areas. These ensured fuels were fit for purpose and helped vessel operators to reduce maintenance costs and downtime while improving engine efficiency - enabling the fleet to switch over to these cleaner burning fuels with confidence.

Infineum cold flow improvers help to prevent wax plugging and deposition issues, ensuring trouble free operation with VLSFO

Infineum cold flow improvers help to prevent wax plugging and deposition issues, ensuring trouble free operation with VLSFO

Over recent years other emissions regulations have been tightened and fuel additives have been deployed that can provide tangible reductions of both NOx and black carbon emissions.

Now, the marine industry is intensifying its efforts to curb greenhouse gas (GHG) emissions, with IMO targets set for 2030 to cut CO2 emissions and for a 5-10% use of net zero technologies in support of their ambition to reach net zero GHG emissions by, or around, 2050. That may seem a long way off, but the size of the challenge means change needs to start now.

Infineum is anticipating the potential requirements - developing cost effective fuel and lubricant additive solutions that will support decarbonisation.

On route to decarbonisation, IMO is introducing a number of measures to monitor and reduce carbon emissions. The first annual reporting on carbon intensity will be completed this year and the first A to E ratings will come out in 2024.

The industry is assessing how best to ensure ships gain and retain a C or better rating without significantly increasing running costs. In support, Infineum has invested in the development of new effective, field proven combustion improvers. These easy to implement fuel borne additives not only offer an immediate, zero CAPEX way to cut vessel fuel consumption (which contributes to an enhanced CII rating) but also help to reduce other key emissions, such as NOx.

On the cylinder lubricants side, a new single additive package for 40 BN (base number) marine diesel cylinder lubricants that meets MAN ES category II lubricant standards has been developed. Its detergent and dispersant capabilities control deposit build up, reducing wear on pistons and liners, which translates to higher engine efficiency with reduced maintenance costs and extended time between overhauls. This field proven additive package has been specifically designed to deliver engine protection to ships running on VLSFO and on lower carbon fuels including LPG, LNG, ethane and methanol – supporting a transition to future fuel alternatives. In addition, this product gives end users the peace of mind of using a low BN oil without the need to switch from high to low BN – delivering logistics flexibility without compromising on reliability.

Another already-available carbon reduction option is the use of biofuels, which can be dropped into the existing marine fuel pool. While they can be used without engine modification and almost eliminate sulphur oxide (SOx) emissions, their NOx emissions are generally higher. However, the use of combustion improver fuel additives, along with advanced lubricants, is helping to overcome this challenge - enabling shippers to reduce GHG emissions today.

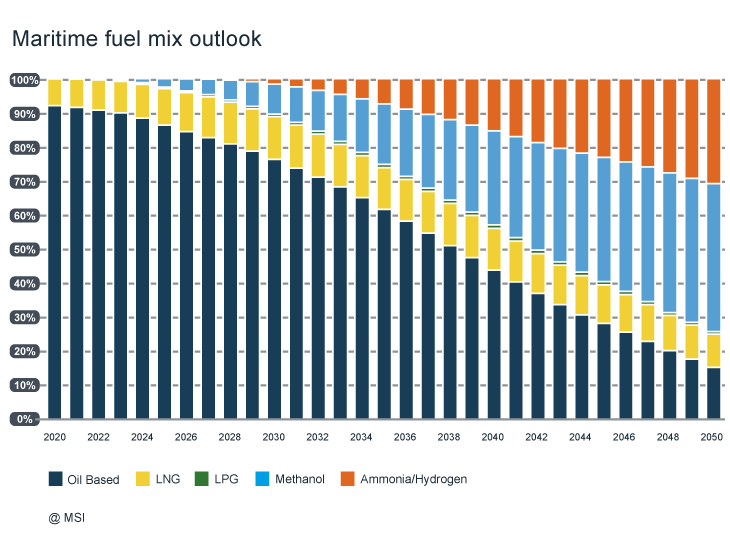

What lies ahead is a diverse multifuel world, with low and zero carbon propulsion energy source solutions likely to be different for each vessel type and sector.

That scenario means fuel supply chain complexity will increase as more fuels become viable. In our view, it will be important to ensure compatibility with these new fuels up and down the supply chain – in the vessel, the bunkering facilities, storage, supply and production - and to ensure new lubricant and fuel additive solutions are fully tested and readily available when needed.

Projects are already underway to assess what is required to support the safe introduction and use of low and zero carbon fuels such as methanol, ammonia and hydrogen. We are actively investigating ammonia combustion in marine engines, which is one of the most promising industry decarbonisation solutions. In our view collaboration is key, and in 2022 we joined the MariNH3 consortium supporting them in securing a £5.5M UK Government grant to fund strategic research in four universities.

Our aim is to be ready with flexible additive solutions that can be used in single, dual or multifuel applications without compromising reliability.

Through these tough times, Infineum fuel and lubricant additives have been trusted by the marine industry to reduce emissions while also protecting hardware to minimise downtime and maintenance costs and improving efficiency to help reduce running costs. With big challenges still to come, lubricant and fuel additives can be expected to play an integral part of many of the solutions.

Improving sustainability is now the key driver for change in the marine industry.

Infineum aims to be a leader on this exciting journey, taking a collaborative approach and engaging on sustainability not just with our customers, but also with our colleagues, suppliers, shareholders, and communities.

Continued investment in innovative chemistries will help support the changes in engine hardware and aftertreatment systems, fuel types and vessel operation that are needed to enable international shipping to meet emissions reduction targets and decarbonisation ambitions.

Sign up to receive monthly updates via email