Marine engines

Fuel additive sea trials

08 July 2025

08 February 2017

Low TPP formulations meet performance requirements without reprotoxicity labelling

Infineum Technologists, Luciana Angonesi and Malgorzata Maranska, explain how a novel detergent is enabling marine lubricants to match the performance of current products while removing the need for reprotoxicity labelling under the Globally Harmonised System.

The Globally Harmonised System of Classification and Labelling of Chemicals (GHS) is a single worldwide system, which was introduced by the UN to help remove confusion about the different ways the hazardous properties of chemicals were assessed and classified via a number of historical national schemes. It also clarifies how information about these hazards is passed to users through labels or safety data sheets.

The GHS aims to introduce the same criteria for classifying chemicals according to their health, environmental and physical hazards and the same hazard communication requirements for labelling and safety data sheets across the globe.

In the marine lubricants world, one chemical that is impacted by GHS is tetrapropenyl phenol (TPP), which has been classified as a reprotoxin.

TPP is used in the synthesis of phenate detergents, which can deliver high temperature performance in marine diesel cylinder lubricants (MDCL).

GHS hazard pictogram

Reprotoxins are substances that are known, or presumed, to have an adverse effect on the reproductive ability or on development in humans.

Due to an EU process of harmonisation of the classification of TPP, by March 1 2018 TPP must be classified as a category 1B reproductive toxin.

As a result, the threshold for the labelling of TPP containing formulations will decrease significantly in much of Europe, Middle East and Africa and Asia Pacific in comparison to the previous classification as a category 2 reproductive toxin. This means marine lubricants that contain TPP levels equal to or greater than 0.3% mass will need to carry the appropriate GHS pictogram and hazard phrase. In some countries, notably US and Canada, the classification level for a reproductive toxin is even lower at 0.1% mass.

MDCLs are formulated to protect large two-stroke marine engines, which operate under harsh conditions and typically burn low quality, high sulphur fuel. Additive packages can contain high levels of overbased detergents, delivering base to neutralise acids and organic surfactant (soap) to provide cleaning properties. MDCLs mainly use detergents with an overbased calcium core and different soap types, including alkylated salicylate, sulphonate or phenate.

In today’s engines, combustion by-products can form deposits when exposed to high temperatures in the piston ring zone, which can cause ring sticking and lead to scuffing and excessive cylinder liner wear.

Phenate components are deployed to control these deposits. However, the downside of phenate detergents is that they can contain residual TPP at levels that mean even the finished MDCL must be labelled as reprotoxic. Infineum initiated a project to find a chemistry capable of delivering the required high temperature performance without the health and safety issues associated with the use of prior generation phenates.

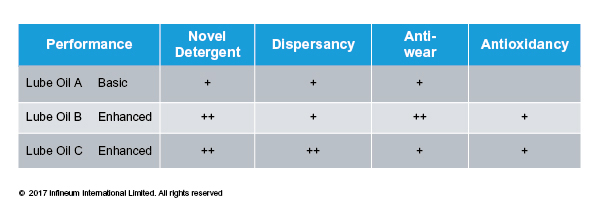

Infineum developed a novel detergent chemistry, which withstands the high temperatures in marine engines, with TPP levels below the labelling threshold. To assess the performance of the new detergent, three test oils were formulated in Group I base stocks to 70 BN at SAE 50.

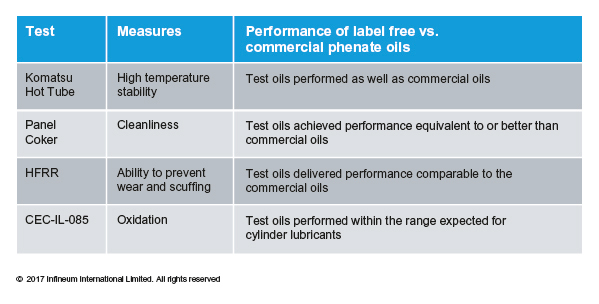

These reprotoxic label free lubricants (referred to as ‘label free’) were compared against commercial MDCL reference oils that, under the new regulations, would carry a reprotoxic label. The oils were evaluated in a number of tests including: the Komatsu Hot Tube Test, Panel Coker test, High Frequency Reciprocating Rig (HFRR) and Pressure Differential Scanning Calorimetry (CEC-IL-085).

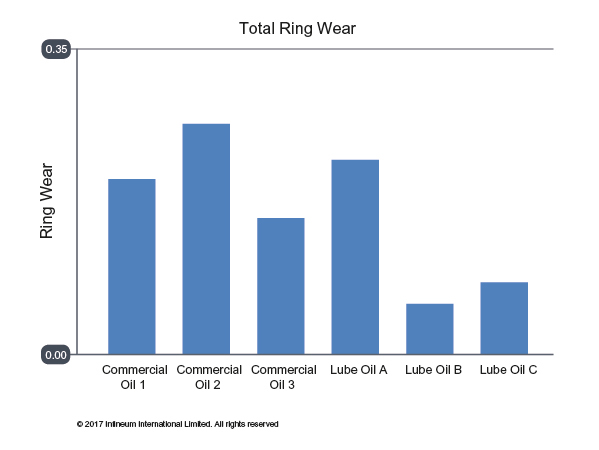

The Bolnes 1DNL engine test is generally used to screen cylinder oils prior to their evaluation in the field. Oils are assessed for control of wear and fouling of the piston, piston rings and cylinder liner. In this test the label free oils achieved mechanical wear performance equivalent to or better than the commercial oils.

Total ring wear in commercial reference oils versus the label free technology

The results from bench and engine tests showed that, in terms of thermal stability, wear, oxidation and cleanliness, the test oils can achieve performance equivalent to, or better than, existing commercial oils.

To confirm the excellent laboratory results the next step was to evaluate the test oils in the field.

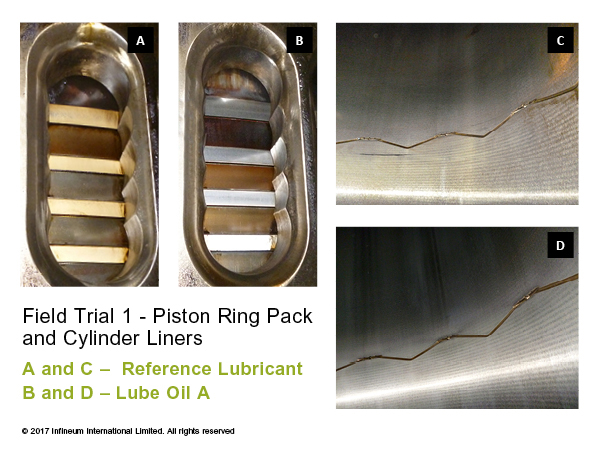

All test oils were assessed in >4,100 hours of field operation in a 8749 TEU container ship with a deadweight of 103,800 tons, powered by a MAN B&W Tier 2 12K98ME-6 engine, which develops ~68,640 kW. The engine was run on heavy fuel oil, except when in emission control areas, and was slow steaming for a significant period with one turbocharger cut out. Test cylinders were segregated so test and reference oils could be compared.

At the end of the trial all of the liners were found to be in good condition, free of deposit and lacquer.

In addition, on board liner scan analysis did not report any concerns or detect any scuffing. The pistons were also very clean with minimal deposits in the grooves and lands.

Piston ring pack and cylinder liners

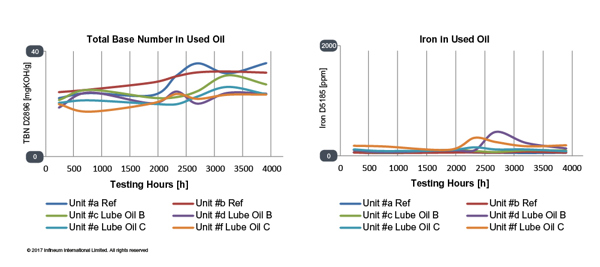

These results indicate that label free formulations can deliver equivalent performance in terms of cleanliness to the commercial MDCL. In addition, in cylinder drain oil analysis, the label free technologies delivered similar performance to the commercial oil.

Used oil analysis base number and iron from reference and test oils

The results of this study clearly indicate that MDCLs can be reformulated to avoid the reprotoxicity harms caused by the presence of TPP without compromising performance.

All of the oils tested have now been OEM approved and are available as reprotoxic label free options for MDCL applications.

Sign up to receive monthly updates via email