Passenger cars

Severe hybrid engine oil testing

20 May 2025

13 May 2015

Understanding nitration and oxidation is key to increasing engine oil lifetime

Knowing when an engine oil has reached the end of its useful life is crucial. And to do this, explains Dave Coultas, Infineum Lubricants Development Technologist, it is increasingly important to fully understand the processes involved, and to ensure test conditions mirror real world scenarios.

Lubricants reside in the piston zone for longer and areexposed to NOx at higher temperatures

As engine oil technology has advanced to meet growing demands for extended drain, enhanced protection and fuel economy it has become increasingly difficult to understand oil degradation mechanisms. What’s more, the introduction of novel additive chemistries, and the highly complex conditions oils encounter throughout their time in today’s engines has complicated matters even further.

The advancement of engine technology through downsizing and the introduction of direct injection gasoline engines present a challenging environment for the engine oil. Not only do these hardware changes mean increased specific power density and higher lubricant temperatures, but also reduced lubricant volumes mean the lubricant resides in the piston zone for longer and is exposed to NOx at higher temperatures. All of these changes point towards higher nitration and oxidation and much faster oil degradation.

Parameters including total base number (TBN), total acid number (TAN), wear metal analysis (including iron, lead and copper) and nitration and oxidation have all traditionally been used to study the effects of oil degradation.

The methods of analysis employed to determine oil degredation some 30 years ago are still the primary techniques used to monitor engine oil quality today.

Although they go some way to helping us qualify the condition of the oil, what is really missing is a method that conclusively answers the most important question: when has the engine oil reached its condemnation point? This is a particularly pertinent question for Infineum as we work to maintain and even increase engine oil lifetime with novel additives and formulation approaches whilst working within ever-tightening chemical constraints.

To better understand the impact of oil degradation on lubricant performance Infineum focused on two specific areas, which are of particular importance to the end user and OEM.

The first area of research was determining the true base reserve and acid content of the lubricant over the drain period, and the effectiveness of current techniques to accurately measure these properties. By examining the behavior of weak and strong acids with standard additive systems we were able to develop a deep insight into the acid neutralisation processes.

In today’s engines operating under harsh conditions and running on low sulphur fuels, we have concluded that the weak acid case is more pertinent. This work also revealed the strengths and weaknesses of the techniques used to measure lubricant base and acid content and signposted ways for optimised methods to better interpret the point at which a lubricating oil has passed its useful lifespan.

Infineum has been working to better interpret the point at which engine oils pass their useful lifespan

The second area of focus was the nitration and oxidation of the lubricant and how this impacts oil degradation. For nitration this meant looking at its sources and measurement in engine oil and monitoring how levels have changed over time. In addition, by exploring the importance of higher nitration and how, in conjunction with oxidation, it influences oil degradation we have gained an understanding of just how important nitration is to the end user and OEM.

Infrared (IR) absorbance has long been used to measure both nitrate ester and carbonyl. These species are generated in the combustion process through the reaction of free radicals with NOx and oxygen. However, the height of the nitration and oxidation peaks on the IR spectrum is not a reliable indicator of the reaction rate because the absolute rate of oxidation and nitration is influenced by many factors including:

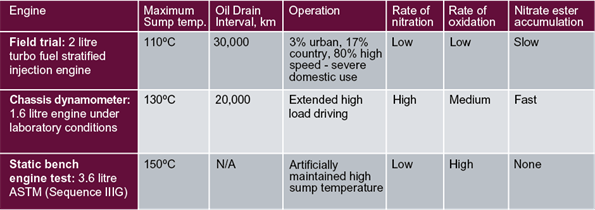

To assess the effect of temperature, Infineum studied a single lubricant formulation in three different engine environments with very different sump temperatures.

These tests demonstrated the tendency for the nitration rate to initially increase then decrease with rising temperatures, while oxidation continually increased as the temperature rose.

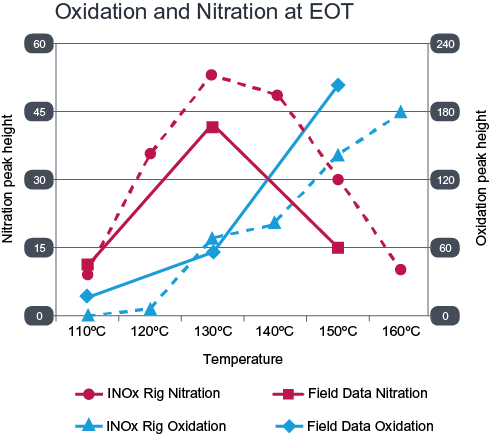

Infineum has developed a simple laboratory test, the INOx rig, so that this phenomenon can be studied in a laboratory test environment. By bubbling a mixture of NO2 and air through the lubricant at various temperatures Infineum established that the nitrate ester peak is temperature dependent. Using the same oil as in the previous tests it was clear that the nitrated species decomposed rapidly at higher temperatures at which point oxidation rapidly took off. This was aided by the fact that the nitrate ester decomposition fed the oxidation cycle with free radicals.

The close agreement observed between the field and laboratory tests means that the INOx rig can be used as a useful research tool. This will help Infineum to better understand the effect of nitration on oxidation and to formulate robust additive packages fit for the most challenging modern engines.

The Infineum INOx rig

The work undertaken by Infineum gives new insights into the ageing processes of engine oils. We have learned that traditional IR techniques are unable to indicate the rate of nitration and that the height of the nitrate ester peak gives little information about the extent of oil degradation. Equally, running engine tests at artificially high temperatures contributes little to the understanding of ‘real world’ oil condition monitoring, because high sump temperatures engage a reaction path which is not usually present in the field to any great extent.

The INOx rig test agrees closely with the observed rates of oxidation and nitration in real-world test conditions. In conjunction with other traditional indicators of oil degradation, the INOx rig is a valuable tool for research into oil ageing and formulation effects.

Our future research will continue to look at nitration as a key process in the understanding of oil degradation because nitration and oxidation are so closely related in real engine operating environments.

David Coultas presented the oxidation and nitration work at the 2015 UNITI Mineral Oil Technology Congress in Stuttgart in a paper titled ‘New insights into the ageing processes of engine oils’.

Sign up to receive monthly updates via email