Gas Engines

Smooth operation for over 90,000 hours

28 August 2024

Please note this article was published in June 2013 and the facts and opinions expressed may no longer be valid.

01 June 2013

Gas engines demand lubricants formulated to handle specific challenges

Natural gas is leading the way in meeting the global demands for inexpensive, sustainable and reliable power. John Smythe, Infineum Large Engine Lubricants Technical Adviser, explains why crankcase lubricants are unlikely to offer adequate protection to the growing population of gas engines.

As new sources of natural gas are tapped so more and more stationary reciprocating gas engines are being introduced to not only move the gas from wellhead to customer, but also to generate electricity.

But just what makes these engines different from ordinary diesel or gasoline fuelled engines? It is quite literally the methane gas that fuels them that sets them apart.

In a gas engine the fuel is already in the gaseous state so there is no need to vapourise liquid fuel, which means the combustion process is very efficient.

However, gaseous fuel also presents a significant challenge. The lack of liquid hydrocarbons in the fuel means that, unlike a conventional liquid fuel, it has no ability to lubricate the valves. In addition, the high combustion temperatures required to dissociate the strong nitrogen bonds mean gas engines are unique for high oxidation and nitration.

And last, but not least, ash deposits can form in the combustion chamber, which can lead to undesirable engine pre-ignition, detonation and knock.

OEMs and lubricant formulators must not only overcome the challenges presented by the use of ‘clean’ natural methane gas, but also need to address those associated with the increased use of renewable landfill and biogas.

In a highly competitive market, OEMs must look for ways to improve the efficiency of their products. Recent trends in engine design have raised compression ratios and turbocharger pressures to increase power output and efficiency.

At the same time performance enhancements have been introduced to reduce average oil consumption and lengthen oil drain intervals to deliver substantial savings in maintenance and repair costs over the life of the engine.

Operators are also under pressure to keep engines in service while reducing maintenance costs. If reciprocating gas engines used for power generation are not running, they are not earning money and pipeline compressors must operate non stop at high capacity to deliver gas to the customer.

Operators are under pressure to keep engines in service while reducing maintenance costs.

Operators are under pressure to keep engines in service while reducing maintenance costs.

This means engines must stay reliably in operation for long periods of time, which presents a real opportunity for marketers to offer lubricants that can deliver durability and longer drain intervals to cut engine downtime and reduce both labour and waste oil disposal costs.

So what does this all mean for the lubricant? Well, with lower lubricant volumes, longer oil drain intervals, more severe operating environments plus demands for improved cleanliness, corrosion prevention, and reduced maintenance costs, gas engine lubricants really must do far more with much less!

Lubricant formulations for ‘clean’ gas engines must be able to handle the high oxidation and nitration stresses of gaseous fuel. In addition a careful balance must be struck on the level of sulphated ash in the formulation. Too much and deposits can form in the combustion chamber, which can result in pre-ignition and valve torching; too little and insufficient acid neutralisation is provided, and the valves are not sufficiently protected.

While it is important for gas engine oils to offer increased oil drain intervals it is also essential that they maintain engine life, durability, and reliability over the lifetime of the engine.

Gas engine oil requirements:

The anticipated growth in the use of bio and landfill gases presents even more of a challenge to the lubricant formulator. While clean, refined, pipeline natural gas contains pure methane and clean-burning hydrocarbons, landfill gas and biogas contain significant levels of CO2, sulphur and chlorine, which can form acids during combustion.

The anticipated growth in the use of bio gas presents challenges to the lubricant formulator.

The anticipated growth in the use of bio gas presents challenges to the lubricant formulator.

In addition, landfill gas can introduce silicone from waste, which during combustion can form hard siloxilane deposits on the cylinder heads and valves, potentially leading to serious damage. As more gas sources are utilised it is essential that gas engine oils are carefully formulated for each type of service.

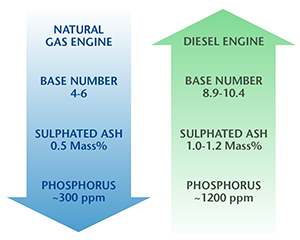

As OEMs seek to protect their aftertreatment systems, the levels of ash and phosphorus in passenger car and heavy-duty engine oils have been decreasing. However, levels are still significantly higher than those required to control deposits and ensure catalyst compatibility in gas engines. This means that conventional crankcase lubricants are not suitable for use in today’s gas engines.

It is increasingly essential to ensure that lubricants are carefully designed to deal with the harsh conditions in the gas engine whilst delivering the necessary protection and maintaining drain interval.

Calcium salicylates are industry-leading detergent components used in the formulation of top tier engine lubricants. In gas engine formulations, they provide strong acid neutralisation capability and help strike the right balance for sulphated ash content to prevent undercrown piston deposits.

Gas engine lubricants formulated with Infineum salicylate additive technology can decrease the amount of deposits within the engine, deliver enhanced engine reliability and help to ensure trouble free operation.

These advanced and specialised lubricants have demonstrated their ability to leave piston crowns, valve faces and the engine visibly cleaner than products, based on other detergent chemistries.

This is clearly a very exciting and challenging time for gas engine OEMs and operators. Infineum is working closely with lubricant companies to develop high quality oils based on salicylate technology that are specifically designed to meet the needs of this growing market.

Sign up to receive monthly updates via email