Passenger cars

Severe hybrid engine oil testing

20 May 2025

24 September 2019

Passenger car powertrain electrification generates new challenges

The increase in the number of hybrid vehicles presents not only lubrication challenges but also exciting opportunities for new technology developments. Simon Moizan, Senior Research Engineer at Infineum, explains how, in this changing vehicle landscape, finding the right additive chemistry balance is more important than ever before.

There is no doubt that the passenger car powertrain is changing. But, how fast and in which direction is still a matter of uncertainty. The drivers for change to future mobility policy are well understood. They include the need to improve air quality to reduce risk to health and to cut greenhouse gas emissions, which are influenced by factors such as governance, ownership models and technology advances.

The complex goals and broad influences, all of which are in constant flux, mean vehicle OEMs are developing multiple solutions to address the challenges, while still trying to build affordable cars that people will want to drive.

There are just so many energy options – electricity, natural gas, liquid petroleum gas, enhanced petroleum based fuels, hydrogen and ethanol. The market traction of each is dependent on a number of factors including: raw material cost and availability, consumer preference, the extent of refuelling infrastructure, government incentives and taxation. Despite the uncertainties, in many regions, OEMs have started to increase the number of models in their line-up with some level of powertrain electrification.

Global passenger car sales have risen from some 70 million ten years ago to over 95 million in 2018. Over the same period the market has moved from being powered almost solely by the internal combustion engine (ICE), to one in which 50% of passenger cars incorporate some level of electrification – from start-stop systems to full battery electric. However, despite the media hype that implies the market is quickly electrifying, new energy vehicles (NEV), where the motors provide power to the wheels, currently account for just 2% of global car sales.

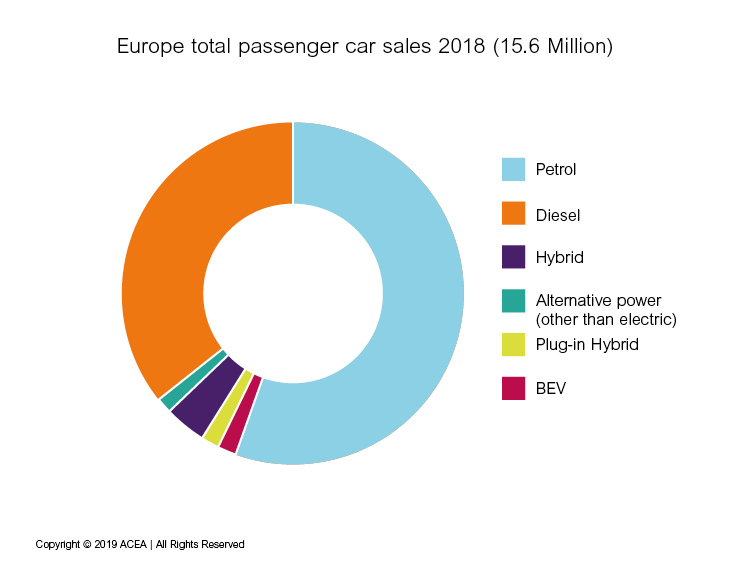

Taking a closer look at three of the world’s major car markets, in the largest, China, more than 23 million cars were sold in 2018, and here deliveries of NEV surged past the million mark reaching 4.5% of car sales. In North America, while Tesla is experiencing strong growth, NEV accounted for less than 1.5% of the 17 million cars sold in 2018. Over in Europe, while diesel sales were down in 2018, conventional ICE cars still made up more than 92% of sales in the region and only 2% of new cars were electrically chargeable.

In 2018 electric vehicles accounted for just 2% of Europe's passenger car sales

In 2018 electric vehicles accounted for just 2% of Europe's passenger car sales

Looking ahead, new vehicle sales are forecast to continue to rise steadily, as is the trend for powertrain electrification. Hybrids represent the best technology solution in terms of well-to-wheel emissions, energy efficiency and driver experience, outside of a pure city driving cycle. This fact, combined with the higher purchase price of full battery electric vehicles (BEV) and constant competition from public transport and other modes of transportation, means that while there is potential for broader adoption of BEV, their uptake is likely to remain fairly limited.

Some industry commentators suggest BEV purchase price could reach parity with their ICE counterparts, without the need for incentives, within the 2025-35 timeframe. While this could result in their wider adoption, future government policies regarding charging infrastructure, penalties and restrictions for ICE can be expected to impact the pace of BEV expansion. In addition, should policies be introduced to apply the current fuel tax rate to electricity then the total cost of ownership parity could be pushed back by another decade of technology development.

The trend toward shared, autonomous, connected and electric vehicles will continue to challenge the organisational resource priorities of the automotive industry

To meet future mobility policy requirements, each OEM will likely respond in a way that best suits their organisation. This means a very wide range of strategies are likely to emerge, creating challenges and opportunities through the entire transportation value chain.

The lubrication challenges associated with conventional ICE crankcase lubricants, including engine and aftertreatment protection, fuel economy, fuel type flexibility and extended oil life, will also apply to these new vehicles. However, as the number of NEV with larger battery capacities grows, their exact form and relative priority may well change and new focus areas could emerge.

Lubricant manufacturers will need to engineer products to meet the needs of an exponentially increasing array of engine technologies: ICE, motors, and batteries, all with different performance capabilities and presented in various powertrain configurations.

In our view, a continuing move towards higher quality lubricants can be expected in all global markets.

By engaging with multiple OEMs, it has been possible for Infineum to assess the main challenges they are experiencing regarding their hybrid vehicle line-up. As a result, a number of research initiatives have been undertaken to assess different hybrid configurations, driving cycles and tailored lubricant formulations.

Current methods for hybrid vehicle performance analysis have typically evolved from tests designed for ICE testing, which present a number of limitations.

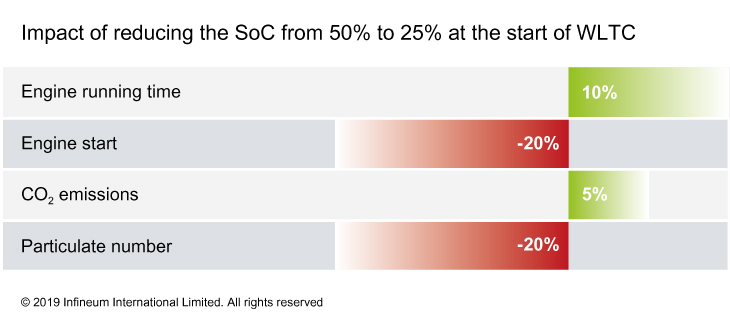

One recent study, to explore fuel economy and powertrain electrification, has shown that both CO2 and particulate number results can be highly influenced by the state of charge (SoC) of the battery at the start of the Worldwide harmonized Light vehicles Test Cycle (WLTC), which indicates that vehicle conditioning is now more important than ever before.

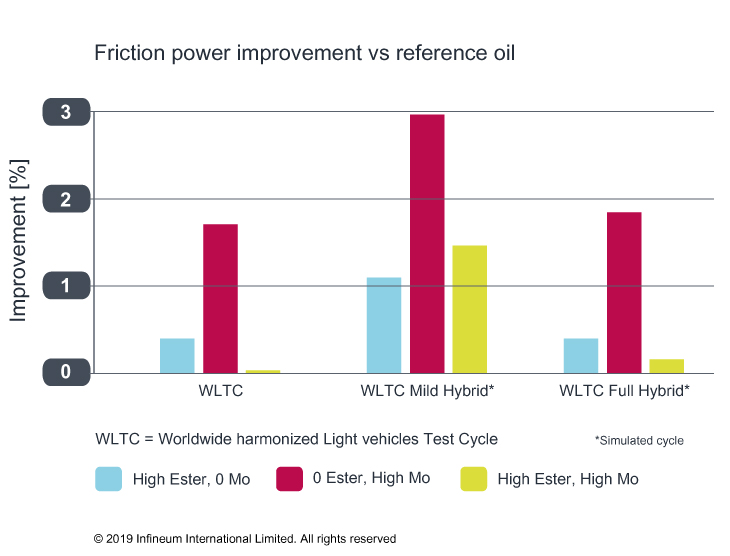

The need to improve fuel economy is a big driver for OEM technical development and investment programmes. With this in mind, Infineum also wanted to further explore the effect of various lubricant formulations on engine friction in various hybrid configurations. The motorised rig results show that both ester and molybdenum booster additives have the ability to reduce friction losses. However, if the boosters are combined into a single formulation, these benefits do not add up.

While both ester and molybdenum boosters reduce frictional losses, combining them diminishes the benefits

While both ester and molybdenum boosters reduce frictional losses, combining them diminishes the benefits

It is evident that not all hybrid technologies are the same, which means careful tailoring of lubricant formulations for these applications is absolutely critical. In addition, the experience gained from our research initiatives highlights the need for testing legislation to evolve to better qualify hybrid vehicles so that end users are properly informed.

Looking to the future, economic growth is expected to drive increased requirements for transportation and, as we move to a lower carbon footprint globally, new lubrication challenges will arise. Innovation is key; in particular there will be a need to respond to the emerging needs of more efficient and lower emitting ICEs, the use of lower carbon fuel sources and hybridised vehicles.

Future lubricants will need to handle the specific needs of engines characterised by intermittent operations, cooler temperatures, and longer periods of inactivity, whilst delivering hardware protection, electric-system component compatibility and exceptional performance when called to action. However, not all hybrids are the same, and there can be no one-size-fits-all lubricant solution.

To engineer tailored lubrication solutions for NEV it is now more important than ever to select the appropriate test methods and conditions to determine the best additive balance.

Infineum is using the entire capability of its product portfolio and the expertise it has gained by working closely with leading hybrid OEMs to design lubrication solutions that address the emerging challenges.

Sign up to receive monthly updates via email