Driveline

Balancing efficiency and durability

20 May 2025

23 August 2021

Overcoming the challenges of optimising fluids for increasingly electrified powertrains

As OEMs strive to meet ever tightening greenhouse gas emissions mandates, the pace at which they are electrifying the passenger car powertrain is accelerating. Zhao Gang, Infineum Power Transmission Fluid Portfolio Manager, explores the latest trends and assesses the challenges facing fluid formulators as they look to balance transmission hardware protection with the very specific e-properties hybrid and battery electric vehicles require.

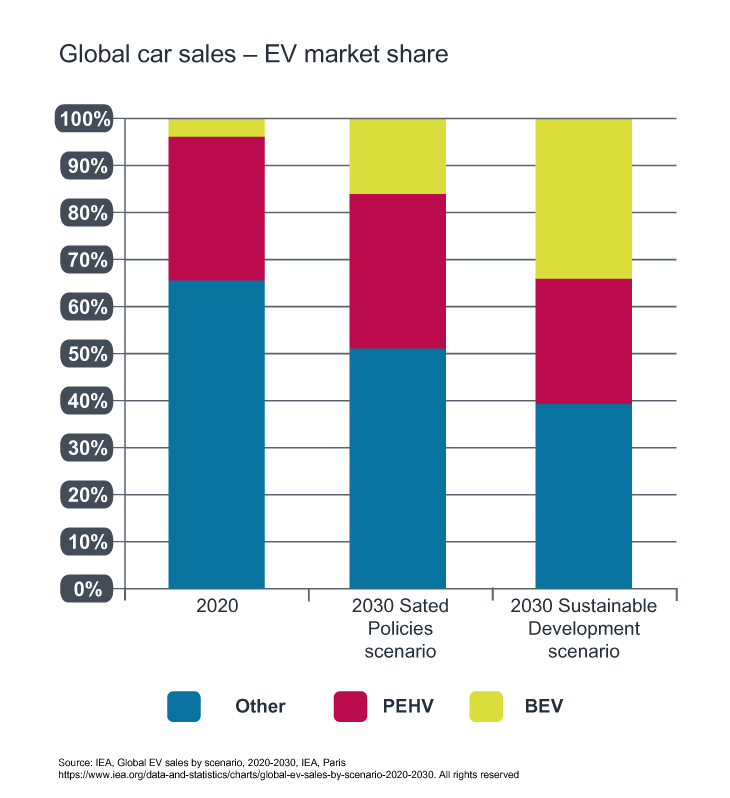

The forecasts by industry analysts regarding the pace of vehicle electrification vary widely and the segmentation of hybrid, plug in hybrid and battery electric can make it hard to compare the various figures. IEA has applied two scenarios to its analysis, the ‘stated policies’ and ‘sustainable development’, which result in two very different pictures by 2030.

Industry analyst figures tend to hover around 26-30% of global sales being battery electric in this timeframe. What all of the forecasts reflect is the decline in sales of vehicles solely powered by internal combustion engines and a growth in sales of electric vehicles (EVs). Bloomberg NEF for example suggests that by 2040 all EV types could account for over 80% of new sales globally. Despite the uncertainties, as governments and legislators around the globe look to curb greenhouse gas emissions faster, we can be certain that vehicle electrification will be one part of the solution. This might be in the form of more hybrids, which still use a combustion engine for propulsion, or in range extended or full battery vehicles.

Whatever mix of powertrain solutions are on offer, vehicle electrification poses a number of challenges for the lubricant formulator.

Infineum has been working on the development of e-fluids that can meet the needs of each approach to electrification. Click here to watch our latest video.

As shown in the video, e-fluids must be tailored to meet the differing requirements of each type of system as we move up the efficiency list - through all the hybrid variants to range extended and, at the top, battery electric and hydrogen fuel cells.

In hybrid systems, if the oil is not in contact with the e-motor, then it needs to maintain all the traditional transmission fluid properties such as aeration, oxidation, frictional properties and gear/bearing pump wear durability. However, in a system that contains an oil cooled motor, new e-fluids must also focus on motor cooling, materials compatibility and electrical properties. Meeting these new requirements must be carefully balanced with the need to optimise transmission performance and protection, particularly in a lower viscosity environment, all of which introduces new considerations for component selection in these applications.

e-fluid electrical properties must be considered, along with transmission performance and protection

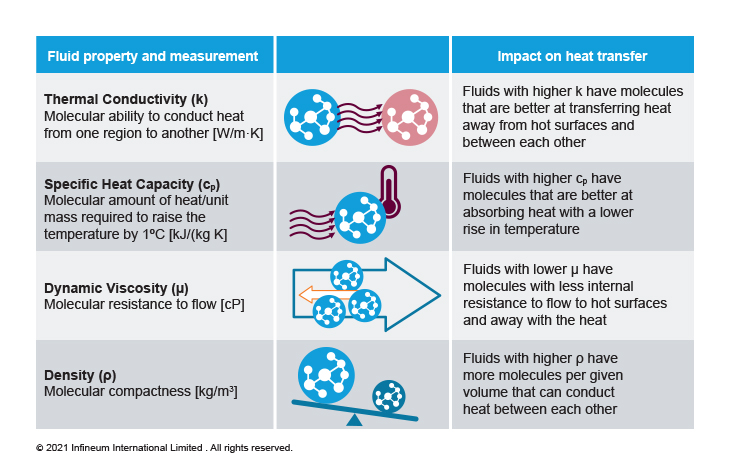

Cooling electric motors, which are responsible for converting electrical energy into mechanical energy, is recognised as a critical function of EV transmission coolants. A number of key parameters can impact the heat transfer properties of the fluid:

Our investigations, conducted in-house and at external testing laboratories under a variety of operating conditions, indicate that thermal conductivity and base oil viscosity are the most important parameters impacting heat transfer properties. One of the key takeaways of our research was that lower viscosity fluids delayed the onset of stator winding temperatures that cause the motor to function at less than optimal levels.

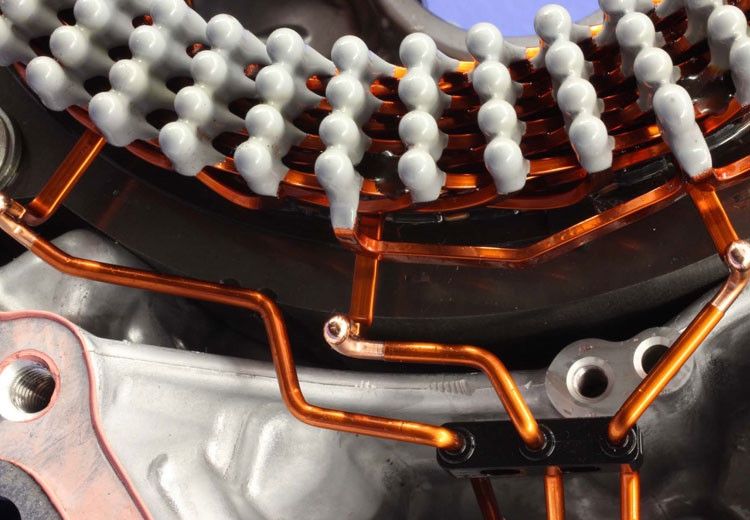

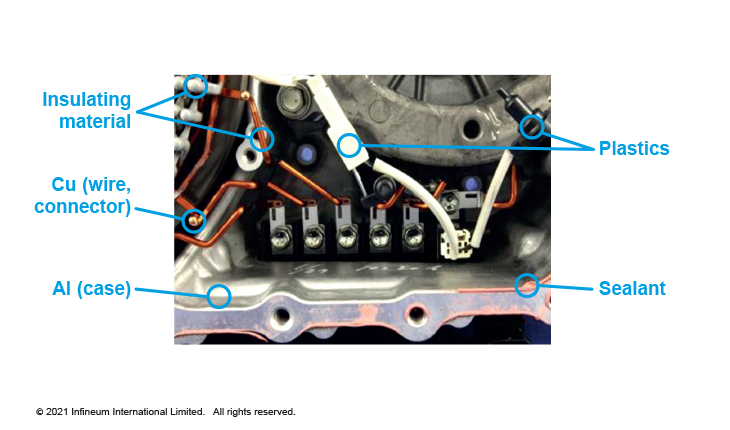

As motors are placed into the transmission a number of materials, different from those used in current engine technology, are being introduced.

Here, since corrosion can lead to electric current leakages or to a short circuit in the transmission, compatibility with the copper wire and connections is seen by many OEMs as the most important design parameter for e-fluids. Infineum has used a number of tests, including ASTM D130 and newer energised circuit board tests, to screen additives to ensure good copper compatibility.

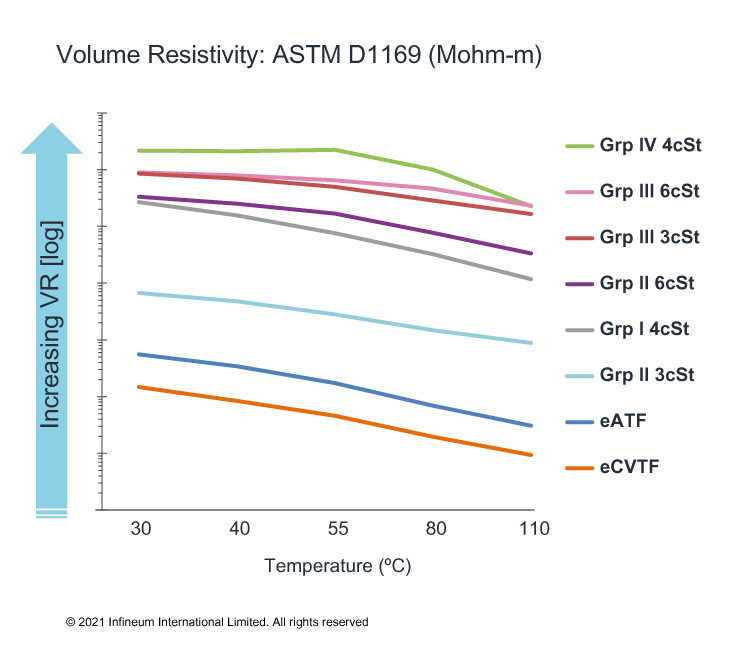

The issue of electrical compatibility over-arches all EV developments. The power electronics of EVs operate at hundreds of volts, which means the fluid also needs to provide enough resistivity to avoid any current leakage. Volume resistivity [VR] is used to measure electrical compatibility, but getting it right is a fine balance. Too low and power outage may result, too high and it can lead to static charge buildup and hardware damage due to arcing phenomena. e-fluids with the optimal resistivity result in low current leakage, which can help OEMs to reduce the size of the casing through smaller e-motors operating at even higher voltages.

Infineum has developed a thorough understanding of the significant impact additives and molecular structure can have on VR.

Our investigations have shown that maximum e-fluid VR is dictated by the base oil, with higher quality and viscosity increasing VR. However, additives can be used to optimise fluid electrical properties to meet the evolving requirements of OEMs.

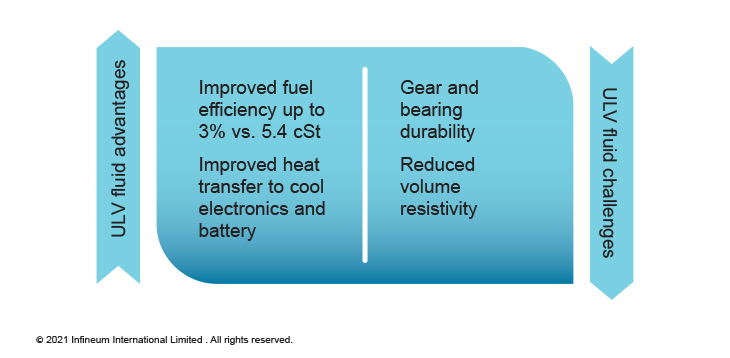

In recent years, to support OEMs as they work to meet ever-tightening fuel economy mandates and targets, transmission fluids have been trending to ultra low viscosity (ULV). In the 1990s, factory fill fluids typically had a kinematic viscosity at 100oC of 8 cSt but today’s fluids can be around 3 cSt. While going to such low viscosities has clear advantages it also presents some formulation challenges for ULV e-fluids.

Careful formulation balancing is necessary in a lower viscosity environment

To solve these issues, Infineum has built on its experience gained in formulating ULV automatic transmission fluids and invested in the development of next generation anti-wear components and step out volume resistivity formulations. Following a number of bench and screener tests these advanced e-fluids have now been tested in extensive field trials.

We will bring you the results of these field trials in future issues of Insight. Meanwhile if you require further details on our dedicated e-mobility products, tailored for every type of electrified transmission application, please contact us here.

Sign up to receive monthly updates via email