Commercial vehicles

ACEA HD Sequences released

22 January 2025

17 May 2022

Mandatory simulation tool lays groundwork for 2025 heavy-duty carbon dioxide emissions targets

In Europe the first carbon dioxide (CO2) emissions targets for heavy-duty diesel trucks and buses have been introduced with initial targets in 2025 that will be further tightened in 2030. It is now mandatory for new trucks, under certain vehicle categories, to determin CO2 and fuel consumption data via the VECTO simulation tool and to report them to the European Commissio. As the industry gets to grips with the new processes, Insight reports on the changes ahead, the options OEMs may adopt to avoid the substantial financial penalties applied for non-compliance with the 2025 targets and the ways lubricant technology can support the changes.

According to the European Commission (EC), CO2 emissions from heavy-duty vehicles including lorries, buses and coaches, represent around 6% of total CO2 emissions in the EU and 27% of total road transport CO2 emissions. With these figures in mind, as the EC works to decarbonise transport it has introduced the region’s first ever CO2 emissions standards for new trucks and other heavy-duty vehicles. The rule, adopted in 2019, means manufacturers will be required to cut these emissions from regulated trucks on average by 15% from 2025 and by 30% from 2030, compared with a reference period from 1 July 2019 – 30 June 2020.

The Commission says the regulation will not only contribute to the achievement of the EU's commitments under the Paris Agreement but also help maintain the technological leadership of European manufacturers and suppliers. In addition it anticipates a number of tangible benefits including:

The penalties for non-compliance with the legislation are substantial, amounting to €4,250 per gCO2 /t-km in 2025 and €6,800 per gCO2 /t-km. To avoid them it is essential for OEMs to ensure their fleet-wide CO2 emissions stay under the target limit.

As part of this work EC introduced a way to provide the technical basis for the new rules by setting out detailed monitoring and reporting methods.

The Vehicle Energy Consumption Calculation Tool (VECTO) introduces a common method to objectively compare the performance of heavy-duty vehicles placed on the EU market.

This means that since January 1 2019, newly produced trucks of a certain class come with a certificate with information on fuel consumption and carbon-dioxide emissions.

VECTO is the new simulation tool that has been developed by the European Commission that shall be used for determining CO2 emissions and fuel consumption from heavy-duty vehicles (trucks, buses and coaches) with a gross vehicle weight above 3500kg. While the regulation currently only applies to larger vehicles, which account for 65%-70% of all heavy-duty CO2 emissions, the inclusion of smaller lorries, buses, coaches and trailers is to be discussed as part of the EU Commission's 2022 review.

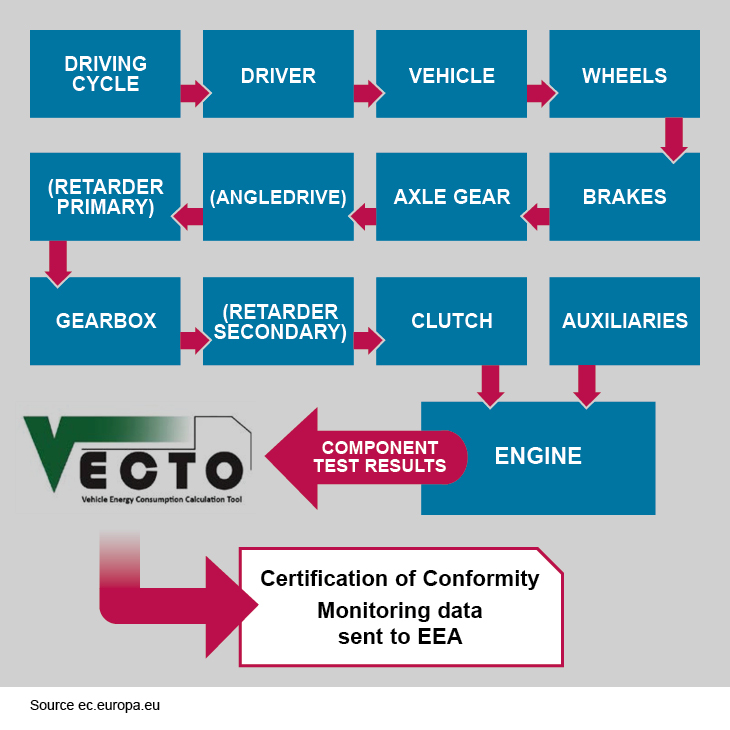

Every 'component' of the vehicle is tested according to EU standards producing input data for VECTO to calculate and validate CO2 emissions for the entire vehicle.

Component testing of the whole vehicle provides input data for VECTO

CO2 emissions are calculated per unit payload (in tonnes) and distance (in kilometers), which means the resulting gCO2/t-km, accounts for the high variation in payload and distance travelled across vehicle subgroups. The information delivered by VECTO provides a certificate of conformity for the customer and the OEM and also monitoring data for the European Environment Agency (EEA).

VECTO looks at families of vehicles, where the parent engine must provide a wide range of data input to VECTO, while every child engine needs to be full load tested only.

VECTO engine inputs:

This parent child relationship may drive OEMs to design and develop engines with more and more shared platforms and commonalities to reduce the testing burden.

Clearly to attract new sales and to comply with the legislation to avoid financial penalties it is vital for OEMs to look for improved efficiency from every element of the vehicle. And, although vehicles with alternative powertrains, such as those using hydrogen and electricity, are being commercialised in this sector, it is likely that most vehicles will still rely on internal combustion engine (ICE) technology for propulsion for some time to come.

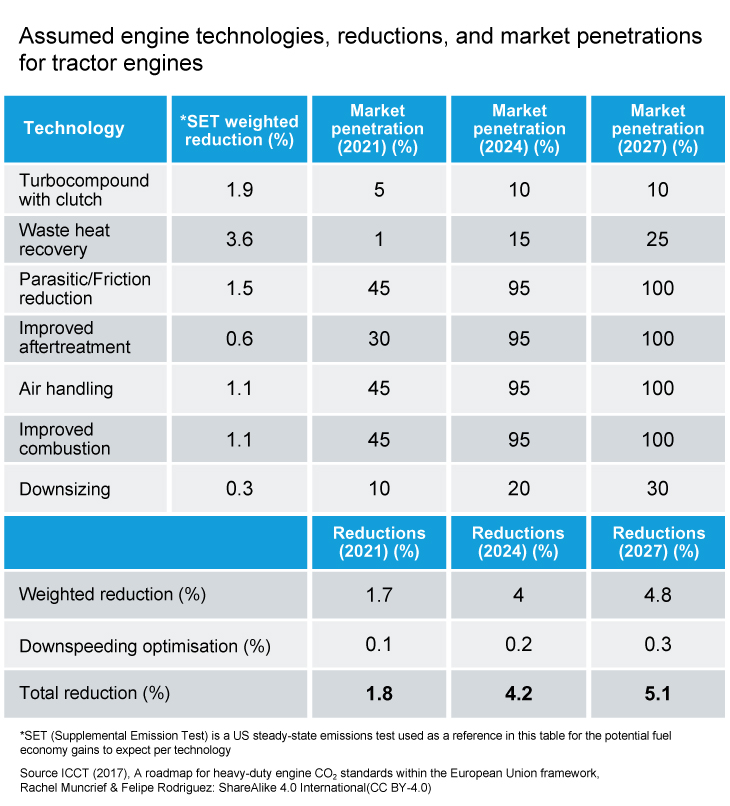

According to ICCT we can expect to see a raft of new technologies being incorporated to different extents into ICE platforms over the coming years – each providing fuel economy benefits:

Some of the highest adoption rates are for parasitic friction reduction, improved aftertreatment and improved combustion. Although this activity means a much harsher environment for the oil in the combustion chamber, advanced lubricants can be designed to deliver sufficient protection while also delivering fuel economy benefits.

Currently, OEMs in Europe use varying viscosity grades applicable to their specific hardware and usage requirements to meet fuel economy targets, with SAE 15W-40 the most commonly used grade today. However, they have been keen to evaluate the performance of lower viscosity lubricants as their use becomes a serious consideration to help them achieve future fuel economy targets. In our view, SAE 10W-40 or lighter grades could account for more than 50% of demand by 2030, with SAE 5W-X grades experiencing some growth.

As viscosity trends to thinner grades there must be no compromise in the engine protection provided by the additive technology chosen.

Infineum has been working with several OEMs to understand the options that can be made available to meet their specific requirements in order to support their ability to maximise lubricants in VECTO performance without any engine protection compromise. Demonstrating the ability of lubricants to deliver frictional benefits via high quality testing, representative of important operating points in the field for the OEMs, is clearly an important consideration for future formulations.

Sign up to receive monthly updates via email