Commercial vehicles

ACEA HD Sequences released

22 January 2025

10 June 2015

Lower viscosity oils present heavy-duty diesel engine protection challenges

Careful evaluation of lubricant shear stability is essential to ensure lower viscosity oils offer sufficient protection to heavy-duty diesel engines. Isabella Goldmints, Infineum Lead Scientist in the viscosity modifier area, describes some of the work being undertaken to explore the viscosity retention of various multigrade engine oils.

Environmental and economic concerns have driven significant change to heavy-duty diesel engines – especially in terms of emissions reduction, noise control and power generation. Despite the fact that these requirements place additional stress on the lubricant, today’s engine oils are increasingly expected to provide uncompromised engine protection over longer drain intervals. Additional complexity comes from OEM requirements for lubricants to deliver fuel economy via reduced frictional losses, which means the viscosity of heavy-duty engine oils is expected to continue its downward trend.

Viscosity modifiers are added to heavy-duty engine oil formulations to increase the viscosity index and produce multigrade oils. These VM containing oils are non-Newtonian fluids, which means their viscosity depends on the shear rate. Two phenomena are associated with their use:

The 90 cycle Kurt Orbahn bench test has been usedsuccessfully to determine the shear stabilityperformance of oils

Since their introduction multigrade engine oils have been subjected to significant testing in order to establish their shear stability as new oil and over their service life.

The 90 cycle Kurt Orbahn diesel injector shear bench test, for example, was designed to simulate permanent viscosity loss in heavy-duty diesel engines. It has been used successfully to determine the shear stability performance of oils, and its correlation to field performance with 2003 and newer engines has been well established.

However, heavy-duty diesel engines have evolved and the severity of the shear environment for lubricants has increased. The need to fully understand these phenomena in the latest engine hardware is essential if we are to ensure oils continue to deliver robust wear performance throughout their life in the crankcase.

To meet North American NOx emissions targets, OEMs initially introduced exhaust gas recirculation (EGR) systems. EGR contributes to soot accumulation in the oil sump, with 4-6% soot being found in drain oils for most pre-2010 engines. This resulted in API CJ-4 oils being designed so that they can carry high soot loadings without exhibiting excessive viscosity increase.

However, to comply with near zero NOx emissions regulations, today’s engines are equipped with more sophisticated exhaust aftertreatment systems, including selective catalytic reduction (SCR). This advanced technology allows engines to operate more efficiently and generates much less soot than pre-2010 engines, which means there is a negligible viscosity contribution from soot accumulation in these engines.

These changes, combined with other significant advances in engine technology, mean that it is now essential to assess the behavior of commercial VM chemistries in current API CJ-4 oils in newer emissions-compliant engines.

At the same time it is also important to ensure the laboratory tests used to evaluate lubricant performance are still doing a good job and correlate well with the performance of lubricants in the field in modern engines.

Viscosity retention throughout the entire drain interval is one of the most important lubricant qualities, and understanding the performance of VMs in multigrade oils has never been more important. With this in mind, Infineum has assessed various VMs in both field and bench studies to gain a real insight into the performance of today’s lubricant chemistries.

The first step in this research programme was to establish lubricant performance in the field. To do this, Infineum ran a field trial to evaluate different VM types in a variety of viscosity grades using engines with high physical shear and low soot generation, typical of modern heavy-duty vehicles.

The two most popular viscosity modifiers are hydrogenated styrene diene (HSD) and olefin copolymers (OCP). SAE 15W-40 and 10W-30 test oils were formulated using these polymers and API CJ-4 additive technology in API Group II base stocks. The oils were sampled throughout the test and at 35,000 mile drain intervals and analysed for a variety of parameters. The first key observation was that for all the test oils both the Kinematic Viscosity at 100oC and HTHS Viscosity at 150oC stayed in grade independent of VM choice.

Wear metals were also of particular interest because as low viscosity oils are used to gain lubricant derived fuel economy, some manufacturers have expressed concern about the ability of low viscosity oils to provide sufficient wear protection. However, in this field trial no wear issues, as measured by wear metals in the used oil, were observed for any of the samples – with no real difference between the various VMs tested or the two oil viscosity grades.

All the formulations used in the field trial were able to deliver sufficient wear protection throughout the duration of the trial. Minimal viscosity loss was also observed over the entire drain interval.

However, lubricant viscosity trends are ever downward and it is important to be ready for the next generation of engine oils. In North America, the PC-11 category is set to introduce a new ‘fuel economy’ sub category – PC-11 B – which will be SAE xW-30 oils with HTHS in the range of 2.9 to 3.2 mPa-s.

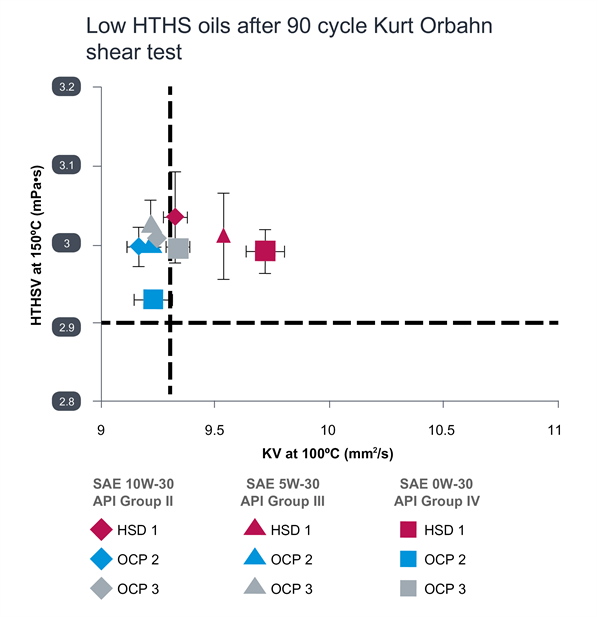

To assess the implications for future PC-11 B oils, a variety of test samples were blended to HTHS viscosity of 3.0 to 3.1 mPa-s and then sheared in the Kurt Orbahn test for 90 cycles and their kinematic viscosity (KV 100) and HTHS viscosity (HTHSV150oC) were measured. The HTHS-KV dependence of these oils is similar to that observed for high HTHS oils. But, because these oils are formulated to the lower limit of the SAE viscosity grade, they tend to drop below the grade limit on KV100 rather than on HTHS after shearing. This means that the Kinematic Viscosity at 100oC stay-in-grade KV100 requirement will be more critical than the HTHS Viscosity at 150oC stay-in-grade requirement when formulating future PC-11 B oils.

The results of these tests indicate that viscosity loss can depend on base oil viscosity and type, lubricant viscosity and polymer concentration. In addition it is clear that the shear stability of the polymers is better in lower viscosity oils even at 90 cycles in the Kurt Orbahn test.

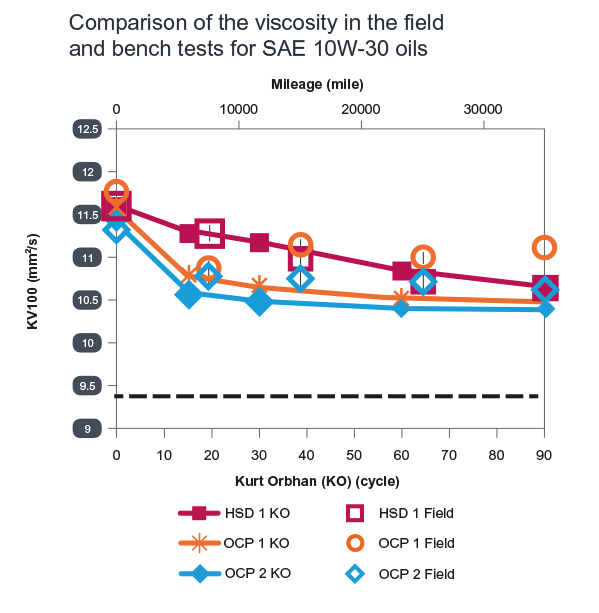

To confirm the results obtained in the laboratory, Infineum analysed the intermediate and 35,000 mile drain samples collected in the field trial. The comparison of the bench and the field data demonstrated that the ASTM method accurately predicts shearing of the polymers in the field even in modern heavy-duty diesel engines.

This research means we can be confident that the 90 cycles Kurt Orbahn bench test is still a good indicator of the viscosity loss and stay-in-grade performance that can be expected when running oils in modern diesel engines.

In our view, selecting a viscosity modifier with a chemistry and architecture that can deliver good shear stability while providing a high contribution to kinematic viscosity will be essential as lubricants are formulated to deliver not only excellent wear protection but also fuel efficiency.

Sign up to receive monthly updates via email