Marine engines

Unlocking the full potential of methanol

16 April 2024

13 August 2019

Finding the right balance of field and bench testing to improve speed to market

Field trials are an essential part of marine oil developments. But, the very aspects that make them the best method for final prove-out of formulations make them unsuitable for assessing novel technology. Insight explores how Infineum is making sure the bench tests it uses to screen new products are more representative of real world performance to help speed up product developments.

Proving the performance for a four-stroke medium speed marine lubricant formulation to ensure optimisation and reduce operational risk is extremely challenging. Field trials are long, expensive, in limited supply and not an acceptable environment for investigating novel and experimental formulations. In the marine lubricant development world, laboratory bench tests that measure physical, chemical or performance properties are used to screen potential formulations. This helps to reduce the cost and time required for lubricant evaluation and to ensure that by the time a candidate is ready to move into full field trials the formulator can be confident that it will not adversely affect ship operation.

Clearly these tests are a critical part of the development of new marine lubricant additive technologies. Current bench tests interrogate individual features of the fluids relatively accurately and can help to provide evidence of likely differences between products. However, there are a number of pros and cons associated with their use.

The key limitation of bench tests in marine lubricant developments is that they are carried out in the absence of fuel, which is a major contributor to many of the parameters under investigation, such as cleanliness and wear. A second shortcoming is that bench tests only consider the behaviour of fresh oil, which is not a true representation of on board operation.

By oversimplifying the variety of complex reactions taking place in an engine, the ability to predict real performance can be lost.

Hardly surprising then that statistical analysis has shown that no current single bench test correlates to any fired engine performance parameters.

With these drivers and limitations in mind, Infineum has taken a close look at the development of efficient and effective tests, using clear, simple processes that deliver meaningful results in which the industry can have confidence. Proprietary modifications to tests have been developed and, when combined with pre-test conditioning of the oil, these allow for better representation of engine performance. In addition, by using a combination of tests, it is possible to gain better insight into lubricant performance in various parts of the engine. At the same time as making bench tests more representative of real world conditions and relevant to modern engines, we are working to ensure they remain a cost effective and credible way to advance new product developments. In addition, limits that are reasonable in terms of preventing the issue of concern and that are commensurate with the precision and accuracy of the measurement tool are being assessed. An evolution, rather revolution, is needed here.

By modifying well-established test methods and assessing new approaches, Infineum is striving to better mimic in-service conditions for some of the key marine performance parameters, such as cleanliness and basicity control.

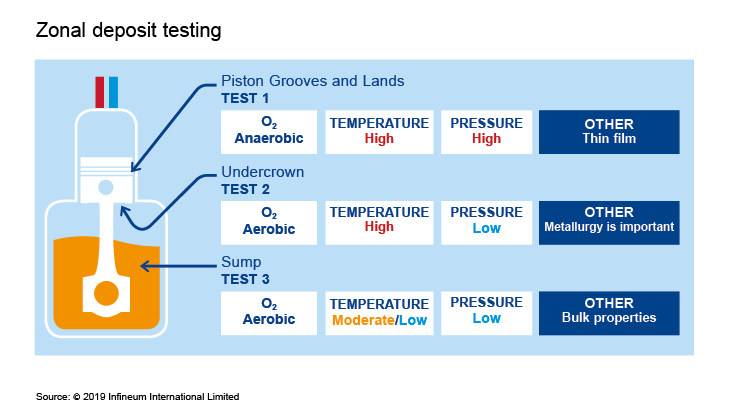

If we look at deposit control as an example, by considering the ‘zones’ where deposits may form and the condition of the lubricant in the field, Infineum has been able to develop new tests and methodologies. Conditioning the oil to a state of partial use and contamination is also important since this can provide a realistic challenge to the additive chemistries. These tests provide a further insight into additive system capabilities and help to identify any gaps that may still exist.

Zonal approach for deposit testing mimics the lubricant conditions at each site

Zonal approach for deposit testing mimics the lubricant conditions at each site

Field performance is a result of multiple degradation pathways and lubricant challenges, something that is impossible to fully replicate in the laboratory. Even the inclusion of these new methods will mean some variables will not be included, for example: shear, blow-by gases, wide temperature profiles and partial fuel combustion. However, the use of bench test data from multiple sources will go some way towards giving an indication of lubricant performance, the strength of the indication being dependent on the number and quality of the tests.

The refined bench test methods developed by Infineum, combined with the use of wider data sets, are being used at the start of the development pipeline to enable our formulators to more easily identify, examine and develop innovative chemistry types. The rate and pace of new formulation developments is increasing since the more valid screener tests allow us to de-risk options before putting a candidate oil forward for full field testing.

In our view, only by running the candidate in a ship’s engine under real world conditions can a ‘true’ representation of performance be gained.

Thus, although refined bench tests are useful development tools they must be used with caution and can never be seen as a substitute for full field trial testing.

Treat rate and cost optimised products, resulting from this bench screening and field prove-out development methodology, are already enabling modern four-stroke marine engines to be operated for longer without compromising the performance of the engine.

Sign up to receive monthly updates via email