Driveline

Balanced e-fluids for commercial vehicles

23 January 2024

12 December 2013

Honda shifts from stepped automatic to CVT transmissions

OEMs are looking for fuel economy gains from every part of the vehicle, including the transmission. Insight talks to Sakai-san, Honda R&D Co., Ltd. Automobile R&D Center, about the benefits delivered by their CVT and DCT technologies.

Honda is constantly looking for ways to achieve improved fuel economy (FE) performance in its vehicles. In North America, the new 2013 Accord comes with a continuously variable transmission (CVT) option, which offers roughly 10% FE improvement over the previous five-speed stepped automatic transmission (AT) model.

“The CVT offers benefits over automatic, dual clutch and automated manual transmissions,” says Sakai-san. “In particular it allows us to utilise the most fuel efficient operating conditions of the engine and delivers constant torque to the wheels, which means improved fuel economy and smooth driving.”

The Honda CVT offers two key benefits - the first being excellent efficiency. “One of the biggest negative impacts on CVT operating efficiency has been the energy consumed by the oil pump,” explains Sakai-san.

“By using precise control technology to reduce the peak pressure at the pulleys we can ensure the oil pump delivers only the required level of pressure, depending on the driving conditions, which means oil pump efficiency is increased to the world’s highest level.”

The second key advantage of the CVT is that the vehicle is fun to drive. In the past, drivers of CVT equipped vehicles had called the response a rather derisory ‘rubber-band-feel’. “We have analysed the undesirable aspects of CVT drive feel as compared to step ATs, and successfully introduced

those highly desirable characteristics into our CVT.”

“In the new 2013 Accord the drivers’ intentions are accurately and swiftly transformed into driving force through precise control between engine and CVT, delivering smooth and dynamic driving which we have not experienced with conventional CVTs.”

Honda is one of the few car manufacturers that produce their own transmissions. In their view, developing engines, car bodies and transmissions under one roof helps to ensure their vehicles deliver smooth and dynamic driving. “What I have learned from my long experience is that harmonisation between the engine and transmission is crucial to controlling the driving force and improving drivability.”

Honda has plans to offer CVTs on almost all vehicle models, and expects the number of models fitted with automatic transmissions to decrease. “Because there is an upper limit on the metal-belt torque transfer capacity there is a corresponding upper limit on engine torque, which means we will not offer CVT on vehicles with large displacement engines.”

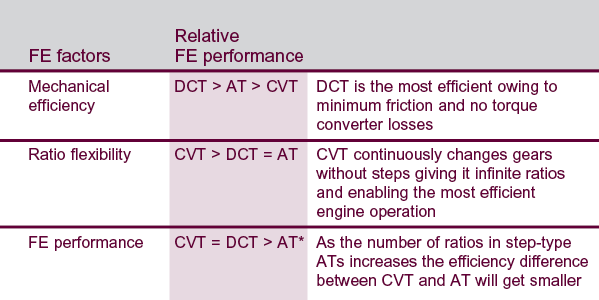

Comparing the fuel efficiency of CVT with AT and dual clutch transmissions (DCT) is fairly complex because a number of factors play a part. However, if we look at the most important factors in FE, which are mechanical efficiency and ratio flexibility, i.e. the ability to seamlessly change ratio between the minimum and maximum value, the following picture emerges:

*These comparisons are based on Honda’s currently available data and on the premise that the AT is a conventional type, and assumes the same overall ratio coverage for the three transmission types.

Honda plans to adopt CVT technology globally. However, because CVTs have an upper torque limit, the company will use other types of transmissions for vehicles with large displacements. For example, in the Accord, the CVT is paired with the 2.4 L engine, but a 6-speed transmission is used for the higher torque 3.5 L engine on the same model.

“We really do not foresee any regional split,” says Sakai-san. “While we recognise that there are regional driving preferences, modes and behaviours, we consider that the general and universal needs for FE improvement and smooth driving performance can be satisfied with CVT.”

To meet the growing demand for CVT Honda plans to increase production in certain regions. “We have plans to increase CVT production in accordance with our fundamental policy of ‘producing in places where the markets exists’. This means we will increase production in regions where Honda vehicles are selling well, specifically Japan, USA, China, Indonesia and Mexico.”

We were keen to understand Honda’s key requirements and performance expectations for CVT fluids. “Fluids become part of the transmission development process right at the start,” explains Sakai-san. “Since fluid performance determines hardware performance, when we set the outline of the new CVT targets we must also set targets for the fluid performance.”

In the future Honda would like CVT fluids to provide performance characteristics that help to improve the CVT’s FE performance by reducing energy loss through better viscosity profiles, breaking the linkage between high steel-on-steel friction and paper friction clutch performance, controlling losses in bearings and gears and extending fluid life.

“By using technologies that can help to improve the steel-on-steel friction coefficient between the pulley and the belt we may be able to reduce the clamping force, which means we will be able to attain further FE improvements and weight reduction,” Sakai-san confirms.

The challenge for transmission fluid producers is to combine as many of these desired characteristics as possible into one fluid.

Generally the life of CVT fluids is shorter than that of conventional AT fluids and because oil maintenance costs are important to end users and vehicle owners, Honda is keen to extend the life of the fluid.

“If all these fluid attributes can be realised, the performance of Honda’s CVT could dramatically improve, and we would be able to provide greater value to our customers who purchase Honda vehicles equipped with those technologies.”

Although Honda is moving to CVT for its conventional vehicles, the high mechanical efficiency of DCT technology makes it the technology of choice for their hybrid vehicles. “As the percentage of time that the vehicle is driven by the engine decreases, so do the advantages offered by CVT systems. This has led us to select a DCT system for our hybrids because it provides the highest energy transfer efficiency, which delivers vehicle FE performance improvements.”

DCT is also highly compatible with the hybrid system. The minimal use of additional systems, such as high-pressure oil supplies, means it can minimise energy loss and is extremely efficient for motor-drive mode. In addition the DCT offers a higher potential for weight reduction compared with other automatic transmissions.

Honda has a long list of performance requirements for their DCT fluid:

“A hybrid vehicle normally starts by motor-drive. However, when more driving force is necessary, the DCT is utilised as a starting clutch, which puts a large stress on the clutch and means ‘no shudder’ performance is an absolute must.”

When thinking about future transmission challenges, Sakai-san points out that we need to first envisage the targets that future vehicles need to meet.

“Since building up sustainable society is the common target of human beings, vehicles must make contributions towards that target. For this, Honda considers that vehicles may be required to offer further efficiency and further safety measures while being fun to drive.”

When the electrification age (pure electric vehicles) finally arrives, complicated transmissions may no longer be required. However, Sakai-san suggests that this evolution will take quite a long time to happen, and that in the meantime improvements to existing technologies are essential.

“At Honda, we believe that ‘efficiency improvement’, ‘weight reduction’ and ‘ratio range expansion’ are the key elements of a transmission that need more and more improvement in the future. Fierce competition has just started among AT, CVT and DCT technologies, and we believe break-through technologies, which can dramatically advance these elements are required for all three transmission types.”

Sign up to receive monthly updates via email